24th Nov 2025 07:00

The information contained within this announcement is deemed to constitute inside information as stipulated under the Market Abuse Regulation ("MAR") (EU) No. 596/2014, as incorporated into UK law by the European Union (Withdrawal) Act 2018. Upon the publication of this announcement, this inside information is now considered to be in the public domain.

ASX/AIM RELEASE

24 November 2025

Updated MCB Mineral Resource Estimate

HIGHLIGHTS:

· Gross Global Mineral Resource of 343Mt @ 0.46% Copper and 0.12g/t gold (0.2% Cu cut-off)

· 1.6 million tonnes of contained copper and 1.4 million ounces of contained gold

· Measured category of 49Mt @ 0.60% Cu and 0.19g/t Au (0.2% Cu cut-off)

· Total high-grade core of (0.5% copper cut-off) of 99 million tonnes @ 0.79% copper and 0.24g/t gold in the Measured and Indicated category

· Overall, the 2025 MRE has an additional 5Mt containing 14kt total copper compared with the 2022 MRE

_______________________________________________________________________________

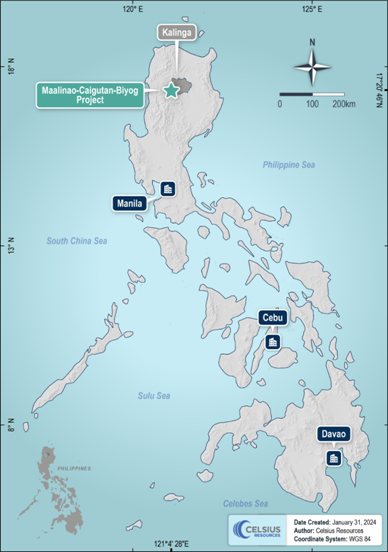

Celsius Resources Limited ("Celsius" or "the Company") (ASX,AIM:CLA) is pleased to announce an updated JORC compliant Mineral Resource Estimate ("MRE") for the Maalinao-Caigutan-Biyog Copper-Gold Project ("Project" or "MCB"), held under its Philippine Affiliate Company, Makilala Mining Co., Inc. ("MMCI") and located at the Island of Luzon in the Philippines (Figure 1).

The Global MRE is now 343 Mt of 0.46% copper, and 0.12g/t gold, for a total of 1.6 Mt of contained copper and 1.4 Moz of contained gold reported to a preferred lower cutoff grade of 0.2% copper.

The drilling during 2022[1] and 2025[2] was all within the boundaries of the prior Resource estimates for MCB (Released in 2021[3] and 2022[4]. The drilling activity was to obtain samples for a metallurgical test work program to determine recoveries from years one (1) to five (5) of the mine life along with further geotechnical investigation of the underground drilling to support an updated underground mine plan. This has allowed for an increase in the confidence level to the Measured category in addition to a refinement of the boundaries to the Mineral Resource. This revised MRE is being utilised for the delivery of the JORC mining reserve along with further increased confidence in the mine plan which will be included in the updated Feasibility Study and the front-end engineering ("FEED") due for release in December 2025.

Celsius has a 40% working interest in MCB. As announced on 20 March 2023 CLA has conditionally agreed to transfer a 60% working interest in MCB to Sodor, Inc, subject to certain conditions, which remain outstanding.

Makilala Technical Director Peter Hume said:

"While the focus of the recent drilling program was established to support the updating of the Feasibility Study and the FEED program, we were pleasantly surprised with further high-grade results."

These results, along with the recently announced recoveries, will further underpin the MCB Project's economic viability and will be the basis of the JORC mining reserve which is part of the updated Feasibility Study and FEED work program"

Table 1. Summary results for the updated MRE at MCB at a cut-off grade of 0.20% copper.

| Gross | Net Attributable | |||||||

Classification | Domain | Tonnes (Mt) | Copper Grade (%) | Gold Grade (g/t) | Copper Metal (kt) | Gold Metal (koz) | Tonnes (Mt) | Copper Metal (kt) | Gold Metal (koz) |

Measured | Type 1HGV | 13 | 1.15 | 0.50 | 145 | 202 | 5 | 58 | 81 |

Type 1HGH | 4 | 0.72 | 0.10 | 32 | 14 | 2 | 13 | 6 | |

Type 3LG | 32 | 0.37 | 0.08 | 119 | 84 | 13 | 48 | 34 | |

Totals | 49 | 0.60 | 0.19 | 296 | 300 | 20 | 118 | 120 | |

Indicated | Type 1HGV | 48 | 0.66 | 0.28 | 316 | 433 | 19 | 126 | 173 |

Type 1HGH | 11 | 0.79 | 0.12 | 83 | 41 | 4 | 33 | 16 | |

Type 3LG | 190 | 0.35 | 0.07 | 674 | 438 | 76 | 270 | 175 | |

Totals | 248 | 0.43 | 0.11 | 1,072 | 913 | 99 | 429 | 365 | |

Inferred | Type 1HGV | 19 | 0.50 | 0.12 | 94 | 72 | 8 | 38 | 29 |

Type 1HGH | 0.1 | 0.80 | 0.14 | 0.5 | 0.3 | 0 | 0 | 0 | |

Type 3LG | 26 | 0.49 | 0.08 | 129 | 71 | 10 | 52 | 28 | |

Totals | 45 | 0.49 | 0.10 | 224 | 143 | 18 | 90 | 57 | |

Total | Type 1HGV | 79 | 0.70 | 0.28 | 554 | 708 | 32 | 222 | 283 |

Type 1HGH | 15 | 0.77 | 0.11 | 115 | 55 | 6 | 46 | 22 | |

Type 3LG | 248 | 0.37 | 0.07 | 922 | 593 | 99 | 369 | 237 | |

Totals | 343 | 0.46 | 0.12 | 1,592 | 1,356 | 137 | 637 | 542 | |

Note for table of results: Estimates have been rounded to the nearest Mt of ore, two significant figures for Cu and Au grade and to the nearest kt of Cu metal and koz of Au metal. Some apparent errors may occur due to rounding.

The MCB Project is an affiliate company of Celsius and MMCI will be the operator of the MCB Project

Changes to the MCB Mineral Resource EstimateThe 2025 MRE incorporates drilling completed by MMCI since late 2022, which has significantly improved confidence in the resource. Additional drilling has strengthened the definition of the Measured category by confirming the continuity of copper mineralisation in key areas.

Recent drilling has also refined the boundaries of the mineralised zones and provided a clearer understanding of the orientation and continuity of higher-grade domains (Type 1HGV). Additional diamond drilling has further defined the shallow high-grade copper mineralisation (Type 1HGH), resulting in improved grade distribution at higher cut-off grades. Overall, the 2025 MRE has an additional 5Mt containing 14kt total copper compared with the 2022 MRE.

The weathering model has also been updated, improving the definition of shallow weathered material. This refined model removes the Inferred category in weathered zones, providing more confidence in these near-surface tonnes. With potential for future mining and processing of this material, the weathered copper mineralisation has been retained within the updated MCB MRE.

Table 2. Comparison between the November 2025 Mineral Resource and the 2022 Mineral Resource at a cut-off grade of 0.20% copper.

MRE | Classification | Tonnes (Mt) | Copper Grade (%) | Gold Grade (g/t) | Copper Metal (kt) | Gold Metal (koz) |

Dec-22 | Measured | 47 | 0.59 | 0.19 | 275 | 282 |

Indicated | 249 | 0.44 | 0.11 | 1,085 | 904 | |

Inferred | 42 | 0.52 | 0.11 | 219 | 154 | |

Totals | 338 | 0.47 | 0.12 | 1,578 | 1,340 | |

Nov-25 | Measured | 49 | 0.60 | 0.19 | 296 | 300 |

Indicated | 248 | 0.43 | 0.11 | 1,072 | 913 | |

Inferred | 45 | 0.49 | 0.10 | 224 | 143 | |

Totals | 343 | 0.46 | 0.12 | 1,592 | 1,356 |

Note for table of results: Estimates have been rounded to the nearest Mt of ore, two significant figures for Cu and Au grade and to the nearest kt of Cu metal and koz of Au metal. Some apparent errors may occur due to rounding.

MCB COPPER-GOLD PROJECT

The MCB Copper-Gold Project (MCB) is located in the Cordillera Administrative Region in the Philippines, approximately 320km north of Manila. It is the flagship project within the Celsius portfolio which also contains other key prospects in the pipeline for permit renewal/extension.

The updated JORC compliant Mineral Resource Estimate (subject of this release) for the MCB Project is 343 million tonnes @ 0.46% copper and 0.12 g/t gold, for a total of 1.6 million tonnes of contained copper and 1.4 million ounces of gold, of which 45 million tonnes @ 0.49% copper and 0.10 g/t gold is classified as Inferred, 248 million tonnes @ 0.43% copper and 0.11 g/t gold is classified as Indicated, and 49 million tonnes @ 0.60% copper and 0.19 g/t gold is classified as Measured.

A Study for the MCB Project was announced by CLA on 1 December 2021, which identified the potential for the development of a copper-gold operation with a 25-year mine life. The Study was based on an underground mining operation and processing facility to produce a saleable copper-gold concentrate.

Highlights from the Study include a Post tax NPV (8%) of US$464m and IRR of 31%, assuming a copper price of US$4.00/lb and gold price of US$1,695/oz. Initial capital expenditure is estimated to be US$253m with a payback period of approximately 2.7 years. The designed mine production is matched to a 2.28Mtpa processing plant which will treat ore with an estimated average grade of 1.14% copper and 0.54g/t gold for the first 10 years of planned production with a C1[5] cash costs at just US$0.73/lb copper, net of gold credits. As at the date of this announcement there are studies ongoing to update the Feasibility Study for the MCB Project which are scheduled for completion by December 2025.

Figure 1. Location of the MCB Project in the province of Kalinga, Northern Luzon, Philippines.

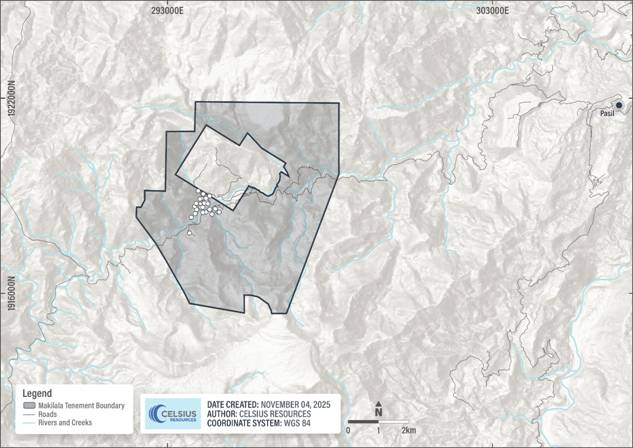

Figure 2. Location of MCB Exploration Tenement area and associated drilling related to the reported MRE.

LocationThe MCB Project is located in Barangay Balatoc, Municipality of Pasil, Province of Kalinga. At the Project area settlements are generally small, compact and occupy a limited area within the main Barangay of Balatoc. The closest major centre is the city of Tabuk which is approximately a 3 hour drive from the Project location.

The Exploration Tenement EP-003-2006-CAR was originally approved in 2006 and had its 3rd renewal approved by the Mines and Geosciences Bureau ("MGB") on 19 November 2020[6]. The Exploration Permit was extended on 31 March 2022 until May 2023. The MGB issued the Mineral Production Sharing Agreement (MPSA-356-2024-CAR) to MMCI on 15 March 2024[7].

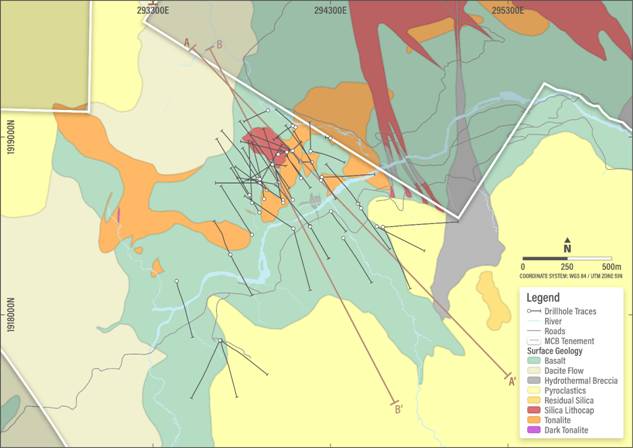

Geology and Geological InterpretationThe geological interpretations and technical information that have contributed to the 2025 MRE at MCB are based largely on surface mapping and analysis of 60 diamond drill holes (31,616.20 m) completed by Makilala Mining (MMCI) from 2006 to 2025.

Drilling at MCB has broadly defined a large-scale copper mineralisation interpreted to be a typical porphyry copper style of mineralisation, common throughout the Philippine archipelago.

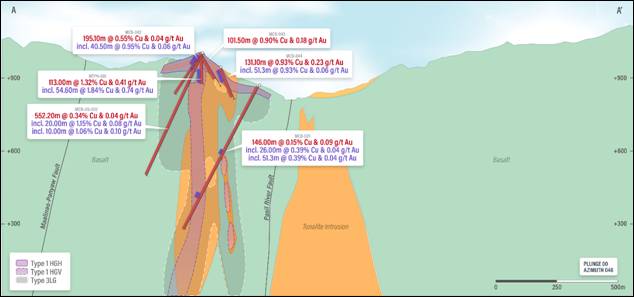

The mineralisation and associated alteration exist across the contact between a genetically related intrusive body (tonalite) and the surrounding host rock material. In most cases the surrounding host rock is an older mafic volcanic rock (see Figures 3 to 5).

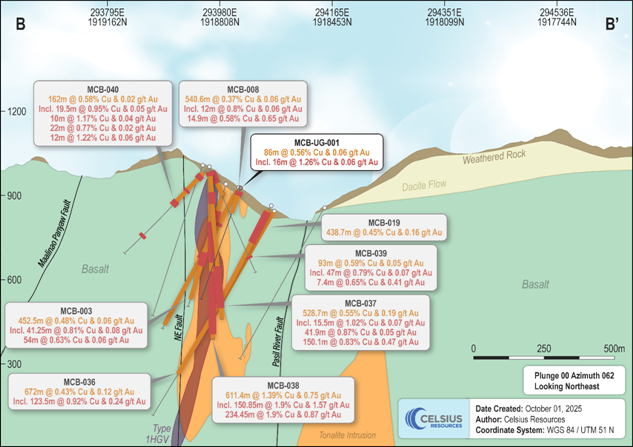

Figure 3. MCB Project drill hole locations and interpreted surface geological plan view diagram

The location and trend of the copper-gold mineralisation is influenced by two dominant structural trends that exist at MCB. The broad fabric and trend of the intrusive bodies and associated alteration extends in a north-east direction, or at approximately 050 degrees with a near to vertical dip. This orientation is also parallel to some major faulting.

The broad copper-gold domains as defined by the MCB MRE were defined based on the continuous zones of copper and gold mineralisation which coincides with the controlling geological host rocks, structures, and alteration features.

Figure 4. Section 1 with the interpreted host rock geology relative to the defined copper mineralised domains. Drill holes completed after the 2022 Mineral Resource Estimate on this cross section are identified (holes MCB-042, MCB-043, MTPH-001, and MCB-UG-002). View looking Northeast[8].

Figure 5. Section 2 with the interpreted host rock geology relative to the defined copper mineralised domains. Drill hole completed after the 2022 Mineral Resource Estimate on this cross section is identified (MCB-UG-001). View looking Northeast.

There is also evidence at MCB for epithermal vein deposit types exist within close proximity to the large-scale porphyry copper-gold mineralisation. At this stage the only deposit type that is defined in the MRE for MCB is a porphyry copper-gold style.

Drilling TechniquesThe MRE was defined using diamond drill holes, which was the preferred drilling method in MCB. Drilling was completed over two broad stages. The first stage was managed by the previous owner of MMCI, Freeport McMoRan, with a total of 25,481 metres from 46 drill holes completed within December 2006 to July 2013. The second drilling program was implemented by MMCI, with a total of 6,135.2 meters from 14 drill holes completed from 2021 to 2025. All diamond drilling utilised a triple tube core barrel for the entire length to ensure maximum sample recovery.

Sampling and Sub-sampling TechniquesHalf core samples were collected from diamond holes drilled from the surface. All drill cores were generally sampled at 2m intervals. In cases where geological and mineralogical characteristics change, the sample length is reduced to best fit the geological contact. The minimum observed sample size is one metre. Sampling typically commenced after the overburden horizon.

The following sub sampling and sample preparations were observed for all the diamond drilling at MCB.

A. Drying and Weighing: Samples were weighed, dried in an oven at 105 Celsius for 6 to 8 hours. For samples with high clay content, drying time is extended up to 16 hours. After drying, samples were weighed again to calculate the moisture content.

B. Crushing: Samples were then primary crushed to a size of <4mm. Using a Boyd crusher, secondary crushing produces <2mm product size. The 1kg crushed material is retained for final preparation.

C. Pulverizing: The 1kg split is pulverized to -200 mesh with a grinding time of 4 to 6 minutes for 1kg ground samples.

D. Splitting: 1kg sample is split successively to obtain four samples of 250 grams each. Out of the four pulp samples, one sample is being dispatched to the laboratory analysis while the pulp samples are retained to be used later for duplicate assays and inter-laboratory checks.

Sample Analysis MethodAll drill samples were prepared and sent to Intertek in Manila, an internationally recognised and ISO-accredited independent laboratory. Gold was analysed using fire-assay methods, while copper and other elements were tested using industry-standard multi-element analytical techniques.

Assay procedures have evolved across the two drilling programs (2007-2013 and 2021-2025), with more recent drilling using updated multi-element, four-acid digestion methods to ensure accurate copper results. Higher-precision analytical methods were used whenever copper values exceeded standard detection limits to ensure the most reliable grades were reported.

Quality control procedures were rigorously followed, with standards and blanks included in nearly 10% of all samples. Independent checks of the laboratory data confirmed no material issues, ensuring the assay results used in the MCB MRE are accurate and reliable.

Estimation MethodologyBased on the general dimensions of the interpreted ore domains, and the likely mining method, a parent cell block size of 10m x 10m x 10m was chosen for the MRE.

Basic statistical information and variogram analysis was reviewed for both copper and gold within the various defined high grade and low-grade domains. The interpreted domains of Type 1HGH, Type 1HGV and Type 3LG were the only 3 domains that were considered to have sufficient data distributed to provide a basis for the use of a more sophisticated interpolation method such as Ordinary Kriging. The parameters for the Ordinary Kriging were based on an analysis of the variograms for each domain. The variograms (defined within the Leapfrog Edge software package) were located along the plane of the interpreted controlling geological trend which is striking at 050 degrees at a near vertical dip.

A broad review of the statistics for each domain did not identify significant high value outliers that are considered likely to result in an overestimated either locally or globally to the grade distribution within the block model. Therefore, no top cut was applied to the MRE.

Classification CriteriaThe Measured portion of the Mineral Resource was generated after the completion of additional drilling results completed during 2022 and 2025. The criteria for the Measured Mineral Resource were based on the first pass interpolation for each domain. This first pass was based on a search of ellipse parameters with a maximum distance of the Sill distance as defined by the variography for each domain. Minimum selection criteria for the Measured criteria also included a minimum of 8 samples from at least 2 drill holes and a maximum total of 18 samples derived from the 2m composited data.

The Indicated Resource for the MCB model was based on a second pass which was defined by a search distance which is~1.5x the Sill distance based off the variogram analysis for each domain. The additional selection criteria for the Indicated category included minimum number of samples of 4 and a maximum of 20 samples derived from the 2m composited data.

The Inferred Mineral Resource was extended for twice the distances applied to the Indicated Mineral Resource using a minimum of 2 samples and maximum of 10 samples defined for each block. No restriction on the number of drill holes was applied for the Indicated and Inferred Mineral Resource category.

Cut-off Grade

A preferred lower cut-off grade of 0.2% copper has been used in the reported MRE. This is considered appropriate based on the geological continuity associated with copper mineralisation above 0.2% copper in addition to a broad economic cut-off point based on a US$5.00/lb copper price.

DimensionsThe copper-gold mineralisation at MCB is classified as a porphyry copper-gold deposit which at deeper levels (below 400m depth) has a broad geometry of up to 1km along strike towards the north-east and true widths of up to 280m. At shallower levels, the copper mineralisation is broken up into multiple domains which are individually up to 600m along strike and with true widths of up to 150m.

Metallurgical and Mining ParametersMetallurgical test work was undertaken by MMCI for multiple defined ore types and over the most common grade ranges considered applicable to a potential mining operation at the MCB deposit. The results highlighted the potential for good recoveries of both copper and gold into a saleable copper-gold concentrate with average recoveries of approximately 95% for copper and 77% for gold (see CLA announcement dated 11 November 2025).

Benchmark mining costs of US$16/t and processing costs of US$10/t respectively for a medium sized (2.25Mt per annum) underground sublevel open stoping mining method and processing using conventional floatation to produce a copper-gold concentrate have been assumed where applicable for the MRE. This cost range estimate matches closely with a broad geological cut-off grade of between 0.2% copper and 0.25% copper (at a Copper Price of US$5/lb).

Table of ResultsThe table below identify the results from the block model at various higher cut-off grades up to 0.5% copper. The ranges identified in these tables define the range of copper cut-off grades on the possible mining options.

Table 3. Summary results for the updated MRE at MCB at a cut-off grade of 0.3% copper.

Classification | Domain | Tonnes (Mt) | Copper Grade (%) | Gold Grade (g/t) | Copper Metal (kt) | Gold Metal (koz) |

Measured | Type 1HGV | 12 | 1.16 | 0.51 | 144 | 202 |

Type 1HGH | 4 | 0.73 | 0.10 | 32 | 13 | |

Type 3LG | 22 | 0.43 | 0.09 | 93 | 64 | |

Totals | 38 | 0.70 | 0.23 | 269 | 280 | |

Indicated | Type 1HGV | 45 | 0.69 | 0.29 | 308 | 423 |

Type 1HGH | 11 | 0.79 | 0.12 | 83 | 41 | |

Type 3LG | 113 | 0.42 | 0.08 | 476 | 275 | |

Totals | 168 | 0.52 | 0.14 | 867 | 739 | |

Inferred | Type 1HGV | 18 | 0.51 | 0.12 | 90 | 70 |

Type 1HGH | 0.1 | 0.80 | 0.14 | 0.5 | 0.3 | |

Type 3LG | 19 | 0.58 | 0.10 | 107 | 58 | |

Totals | 36 | 0.55 | 0.11 | 198 | 128 | |

Total | Type 1HGV | 75 | 0.73 | 0.29 | 542 | 694 |

Type 1HGH | 15 | 0.77 | 0.11 | 115 | 55 | |

Type 3LG | 153 | 0.44 | 0.08 | 676 | 397 | |

Totals | 242 | 0.55 | 0.15 | 1,334 | 1,146 | |

Table 4. Summary results for the updated MRE at MCB at a cut-off grade of 0.4% copper.

Classification | Domain | Tonnes (Mt) | Copper Grade (%) | Gold Grade (g/t) | Copper Metal (kt) | Gold Metal (koz) |

Measured | Type 1HGV | 11 | 1.23 | 0.55 | 140 | 200 |

Type 1HGH | 4 | 0.75 | 0.10 | 31 | 13 | |

Type 3LG | 10 | 0.52 | 0.11 | 53 | 36 | |

Totals | 26 | 0.87 | 0.30 | 225 | 249 | |

Indicated | Type 1HGV | 37 | 0.75 | 0.32 | 282 | 389 |

Type 1HGH | 10 | 0.81 | 0.12 | 82 | 41 | |

Type 3LG | 52 | 0.51 | 0.08 | 267 | 134 | |

Totals | 100 | 0.63 | 0.18 | 630 | 564 | |

Inferred | Type 1HGV | 13 | 0.58 | 0.15 | 73 | 59 |

Type 1HGH | 0.1 | 0.80 | 0.14 | 0.5 | 0.3 | |

Type 3LG | 17 | 0.59 | 0.10 | 103 | 56 | |

Totals | 30 | 0.59 | 0.12 | 177 | 115 | |

Total | Type 1HGV | 61 | 0.81 | 0.33 | 495 | 648 |

Type 1HGH | 14 | 0.79 | 0.12 | 113 | 54 | |

Type 3LG | 80 | 0.53 | 0.09 | 424 | 227 | |

Totals | 155 | 0.66 | 0.19 | 1,032 | 928 | |

Table 5. Summary results for the updated MRE at MCB at a cut-off grade of 0.5% copper.

Classification | Domain | Tonnes (Mt) | Copper Grade (%) | Gold Grade (g/t) | Copper Metal (kt) | Gold Metal (koz) |

Measured | Type 1HGV | 10 | 1.32 | 0.60 | 136 | 197 |

Type 1HGH | 4 | 0.80 | 0.10 | 28 | 11 | |

Type 3LG | 4 | 0.64 | 0.13 | 26 | 17 | |

Totals | 18 | 1.06 | 0.39 | 190 | 226 | |

Indicated | Type 1HGV | 29 | 0.84 | 0.38 | 242 | 346 |

Type 1HGH | 9 | 0.83 | 0.13 | 79 | 38 | |

Type 3LG | 20 | 0.62 | 0.08 | 126 | 56 | |

Totals | 59 | 0.76 | 0.23 | 447 | 440 | |

Inferred | Type 1HGV | 7 | 0.67 | 0.18 | 48 | 42 |

Type 1HGH | 0.1 | 0.80 | 0.14 | 0.5 | 0.3 | |

Type 3LG | 15 | 0.61 | 0.10 | 93 | 50 | |

Totals | 22 | 0.63 | 0.13 | 142 | 92 | |

Total | Type 1HGV | 46 | 0.92 | 0.40 | 425 | 585 |

Type 1HGH | 13 | 0.82 | 0.12 | 108 | 50 | |

Type 3LG | 40 | 0.62 | 0.10 | 246 | 123 | |

Totals | 99 | 0.79 | 0.24 | 778 | 758 | |

Note for table of results: Estimates have been rounded to the nearest Mt of ore, two significant figures for Cu and Au grade and to the nearest kt of Cu metal and koz of Au metal. Some apparent errors may occur due to rounding.

This announcement has been authorised by the Board of Directors of Celsius Resources Limited.

The information contained within this announcement is deemed by the Company to constitute inside information as stipulated under the Market Abuse Regulations (EU) No. 596/2014 as it forms part of UK Domestic Law by virtue of the European Union (Withdrawal) Act 2018.

Qualified Persons Statement

Information in this report relating to Exploration Results is based on information compiled, reviewed and assessed by Mr. Steven Olsen, who is a Member of the Australasian Institute of Mining and Metallurgy and the Australian Institute of Geoscientists. Mr. Olsen is a consultant to Celsius Resources and has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking to qualify as a Competent Person as defined by the 2012 Edition of the Australasian Code for reporting of Exploration Results, Mineral Resources and Ore Reserves. Mr. Olsen is also considered a Qualified Person for the purposes of the AIM Rules. Mr. Olsen consents to the inclusion of the data in the form and context in which it appears.

Definitions

Cut-off Grade | The minimum grade of a mineralised material considered economically viable to process. For this announcement, a preferred lower cut-off grade of 0.2% copper has been applied, consistent with industry practice and economic assumptions. |

Feasibility Study | A comprehensive technical and economic assessment conducted to determine the viability of a proposed mining project. The feasibility study evaluates all key aspects of the project, including geology, mineral resources, mining methods, processing, infrastructure, environmental and social impacts, capital and operating costs, and financial returns. Its purpose is to provide sufficient detail and confidence to support a final investment decision and project financing. The outcomes of a feasibility study typically include detailed engineering designs, cost estimates, implementation schedules, and risk assessments. |

Front-End Engineering Design (FEED) | A detailed engineering phase undertaken prior to the commencement of project construction, during which the technical requirements, design specifications, cost estimates, and project execution plans are developed. In mining, FEED typically includes studies of process flows, plant layout, equipment selection, infrastructure, and environmental considerations. The FEED process provides the basis for final investment decisions and forms the foundation for subsequent detailed engineering, procurement, and construction activities |

Indicated Mineral Resource | The part of a Mineral Resource for which quantity, grade or quality, densities, shape, and physical characteristics are sufficiently well established to allow for a reasonable level of confidence in the estimate, but not as high as for Measured Resources. |

Inferred Mineral Resource | The part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of limited geological evidence and sampling, resulting in a lower level of confidence. |

Measured Mineral Resource | The part of a Mineral Resource for which quantity, grade or quality, densities, shape, and physical characteristics are so well established that they can be estimated with confidence sufficient to allow for detailed mine planning. |

Mineral Resource Estimate/MRE | The estimate of mineral resources as calculated and presented in accordance with a minerals code or standard |

Mineral Resource | A concentration or occurrence of solid material of economic interest in or on the earth's crust in such form, grade (or quality), and quantity that there are reasonable prospects for eventual economic extraction. The location, quantity, grade (or quality), continuity and other geological characteristics of a Mineral Resource are known, estimated or interpreted from specific geological evidence and knowledge, including sampling. Mineral Resources are sub-divided, in order of increasing geological confidence, into Inferred, Indicated and Measured categories |

Type 1HGV | Vertically oriented high-grade copper mineralisation, following geological contacts |

Type 1HGH | Shallow, flat-lying high-grade copper mineralisation, near-surface |

Type 3LG | Broad zones of mineralisation with copper grades generally below high-grade thresholds, modelled for continuity and tonnage estimation |

Forward Looking Statements

Some of the statements appearing in this announcement may be in the nature of forward-looking statements. You should be aware that such statements are only predictions and are subject to inherent risks and uncertainties. Those risks and uncertainties include factors and risks specific to the industries in which the Company operates and proposes to operate as well as general economic conditions, prevailing exchange rates and interest rates and conditions in the financial markets, among other things. Actual events or results may differ materially from the events or results expressed or implied in any forward-looking statement.

No forward-looking statement is a guarantee or representation as to future performance or any other future matters, which will be influenced by a number of factors and subject to various uncertainties and contingencies, many of which will be outside the Company's control.

The Company does not undertake any obligation to update publicly or release any revisions to these forward-looking statements to reflect events or circumstances after today's date or to reflect the occurrence of unanticipated events. No representation or warranty, express or implied, is made as to the fairness, accuracy, completeness or correctness of the information, opinions or conclusions contained in this announcement. To the maximum extent permitted by law, none of the Company's Directors, employees, advisors, or agents, nor any other person, accepts any liability for any loss arising from the use of the information contained in this announcement. You are cautioned not to place undue reliance on any forward-looking statement. The forward-looking statements in this announcement reflect views held only as at the date of this announcement. As at the date of this announcement there are studies ongoing to update the Feasibility Study for the MCB Project which are scheduled for completion by December 2025.

Celsius Resources Contact Information

Level 5, 191 St. Georges Terrace

Perth WA 6000

PO Box 7059

Cloisters Square PO

Perth WA 6850

P: +61 8 9324 4516

W: www.celsiusresources.com

Celsius Resources Limited |

|

Neil Grimes | P: +61 419 922 478 W: www.celsiusresources.com

|

Multiplier Media (Australia Media Contact) Jon Cuthbert |

M: +61 402 075 707

|

Zeus Capital Limited (Nominated Adviser & Broker) Harry Ansell/James Joyce/ James Bavister

|

P: +44 (0) 20 3 829 5000 |

Zeus Capital Limited ("Zeus") is the Company's Nominated Adviser and is authorised andregulated by FCA. Zeus's responsibilities as the Company's Nominated Adviser,including a responsibility to advise and guide the Company on its responsibilities underthe AIM Rules for Companies and AIM Rules for Nominated Advisers, are owed solely tothe London Stock Exchange. Zeus is not acting for and will not be responsible to anypersons for providing protections afforded to customers of Zeus nor for advising them inrelation to the proposed arrangements described in this announcement or any matter referred to in it.

Appendix 1: The following tables are provided to ensure compliance with the JORC Code (2012) requirements for the reporting of Exploration Results for the MCB Project.

SECTION 1:

Sampling Techniques and Data(Criteria in this section apply to all succeeding sections.)

Criteria | JORC Code Explanation | Commentary |

Sampling techniques | · Nature and quality of sampling (e.g. cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down whole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. · Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. · Aspects of the determination of mineralisation that are Material to the Public Report. In cases where 'industry standard' work has been done this would be relatively simple (e.g. 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases, more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (e.g. submarine nodules) may warrant disclosure of detailed information. | · Samples were collected from diamond core drilled from the surface. All drill core was generally sampled on 2-meter intervals. In cases where geological and mineralogical characteristics change, sample length was not less than 1 meter. · Core samples cut into half using diamond core saw following the cutting lines marked by the Geologist. Split cores returned to its respective core tray. · Samples were shipped by company vehicle to Intertek Testing Services which is an external laboratory located in Manila, Philippines. · Crushed samples were fire assayed for gold (Au) using a 30-gram charge, with a detection limit of 0.005 ppm. Gold values greater than 50 ppm were determined by gravimetric fire assay. · Copper (Cu) values were assayed using Four acid digestion. Elements determined by AAS finish with final reporting for a total of 36 elements. |

Drilling techniques | · Drill type (e.g. core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). | · Previous exploration and drilling were conducted between December 2006 and July 2013 by Freeport-McMoRan, completing a total of 46 drill holes with an aggregate meterage of 25,480.55 meters. · An exploration program managed by MMCI commenced in February 2021up to early 2022 with a total of 9 drill holes added to the updated MRE, with a cumulative depth of 4641.7 meters. · Five additional drillholes were drilled in the late 2022 and in 2025 with a total meterage of 1,427.3 meters. · The core drilling utilised a triple-tube core barrel from collar to end-of-hole to ensure optimum core recovery, with the deepest downhole depth being 893.8 meters (MCB-029). · Diamond drilling was used to capture the rock samples for the new drill hole intercepts, with the following drill core size summarized as follows: · PQ sized drill core with a core diameter of 81.1 mm was used from surface to more competent lithology. Core samples of this size are estimated to comprise about 43%of the total length of the recently drilled holes. · HQ sized drill core, with a core diameter of 61.1mm, was then substituted at greater depths to accommodate variations of subsurface conditions. Core samples of this size is estimated to comprise about 57% of the total length of the recently drilled holes. |

Drill sample recovery | · Method of recording and assessing core and chip sample recoveries and results assessed. · Measures taken to maximise sample recovery and ensure representative nature of the samples. · Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. | · Core recovery has been recorded for every interval as part of the routine geomechanical logging. · Recovered core lengths on average were measured to be over 98% for the total length of the drill hole, indicating a high recovery and minimal lost core. · All drilling activities were supervised by company Geologists. Trained Core house Technician were responsible for the core recovery determination. · Core was arranged to fit the breakages before the actual core length from the start to the end of the drill run was measured. Percent recovery was calculated from dividing the measured core length over the total drill run multiplied by 100. |

Logging | · Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. · Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. · The total length and percentage of the relevant intersections logged. | · Geologists were tasked to oversee the daily quick log report down to sampling. Daily quick log form was completed to identify the geological details such as lithology, alteration and mineralisation with corresponding percentage estimate of Cu minerals and Cu grade, using an established geological code. · Detailed logging proceeds describing geological characteristics present in the core, i.e. lithology, alteration, mineralogy, structures, etc. · Core photography was undertaken after completing the geomechanical logging. |

Sub-sampling techniques and sample preparation | · If core, whether cut or sawn and whether quarter, half or all core taken. · If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. · For all sample types, the nature, quality and appropriateness of the sample preparation technique. · Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. · Measures taken to ensure that the sampling is representative of the in-situ material collected, including for instance results for field duplicate/second-half sampling. · Whether sample sizes are appropriate to the grain size of the material being sampled. | · Samples were routinely taken over a 2m interval, and cut in half, with half of the drill core sent for analysis and half of the drill core retained for future reference. · Samples were cut on site using a hand core saw. Samples were then selected and bagged on site prior to delivery to the laboratory (Intertek) in Manila for sample preparation. · The sample size is considered appropriate for type of material being samples. |

Quality of assay data and laboratory tests | · The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. · For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. · Nature of quality control procedures adopted (e.g. standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established. | · Samples were fire assayed for gold (Au) using a 30-gram charge, with a detection limit of 0.005 ppm. Gold values greater than 50 ppm were determined by gravimetric fire assay. Copper (Cu) values were assayed using four acid digestion. Elements determined by AAS finish · The procedures for the submission of samples to the laboratory also include the regular insertion of QA/QC samples in every transmittal form or batch, which was typically delivered to the laboratory in batches of 50 numbered samples. For each batch of 50 samples a total of 43 came from core samples and an additional 7 samples were included for QA/QC checks, which were as follows: o Four referenced standards o One referenced Blank o One coarse (unrecognisable) blank o One field duplicate taken from the quartered core · After sample preparation, all samples were sent for final analysis to Intertek at their laboratory in Manila. Intertek is an internationally recognised and ISO/IEC 17025:2005 & ISO/IEC 17020:2004 certified independent laboratory. |

Verification of sampling and assaying | · The verification of significant intersections by either independent or alternative company personnel. · The use of twinned holes. · Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. · Discuss any adjustment to assay data. | · Analytical procedures provided by an internationally certified laboratory is considered in line with industry standard for the type of deposit and mineralisation identified at the Property. · Apart from the verification of the procedures and results as described above, no further verification of the sampling and assaying have been undertaken. · None of the diamond drill holes in this report are twinned. |

Location of data points | · Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. · Specification of the grid system used. · Quality and adequacy of topographic control. | · All data reference points and maps for the Makilala database, including drill hole collar co-ordinates are recorded in WGS 84/UTM Zone 51N. · Compass measurements taken by Geologists were used to establish the dip and azimuth of the collar hole as part of their initial collar surveys. Drill collar locations were positioned using a handheld Garmin GPS unit, set to UTM WGS 84 Zone 51N coordinate reference system, with an accuracy expected to be within 2 metres. Downhole surveys were also completed using a Keeper Gyro at 50m intervals. · Drill collar locations were recently re-surveyed by Datum Engineering and Surveying Consultancy including elevation checks against an updated drone-based Lidar survey which has a reported "x-y-z" accuracy of 10 cm. · Collar surveys were then logged into the master MS Access database after validation checks were completed against the updated Lidar survey. |

Data spacing and distribution | · Data spacing for reporting of Exploration Results. · Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. · Whether sample compositing has been applied. | · The broad drilling pattern is at 100m spacing for a series of diamond drill holes which are oriented in a north-west direction and dipping at predominantly at 60 degrees. These drill holes are augmented by some drill holes which have a west-north-west orientation or a north-east orientation or are vertical. (see figure 1 for Drill Hole Locations). · Drill holes at the MCB deposit are distributed broadly on eight grid lines, giving coverage of 1,000 metres from east to west. · The drill hole spacing where significant copper-gold mineralisation has been identified is sufficient to determine the geology and grade continuity of the area, as well as the ore body and mineralisation extents. · In the MRE, drill hole assays were composited to 2 metres which matches closely with the sample length down hole for all drill hole sampling completed at MCB. |

Orientation of data in relation to geological structure | · Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. · If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. | · In the resource estimation, drill hole assays were composited to 2 metres downhole intervals. · The dominant trend of the tonalite intrusion, which is directly related to the broader lower grade copper-gold mineralisation has an overall strike of 50 degrees and a sub-vertical dip. Drill hole directions vary relative to this dominant orientation, with some more optimal drill holes dipping at 60 degrees towards 320 degrees. There are a number of vertical drill holes which are not optimal for assessing the geological contacts or grade distribution, however, in most cases these drill holes are also close to other drill holes which are dipping across the mineralised domains, typically at 60 degrees. · There is also a defined horizontal control to the copper-gold mineralisation which appears to extend away from the source feeder structures which are vertical in orientation. Some shallow drilling was completed to fill in gaps in the drill hole data existed where possible, often at 50-to-60-degree angles which are considered still reasonable for testing the horizontal orientations identified as part of the copper-gold distribution at MCB. |

Sample security | · The measures taken to ensure sample security. | · The following standard procedures were enforced for the drilling of new intercepts: o Sample bags are arranged in sequence according to its sample number. These are then weighed and jotted down to a sample dispatch note which details the sample numbers, sample type and laboratory processing required. Geologists ensures that the transmittal form is correct for encoding and submission. The bags of samples are sent directly to the Intertek Laboratory in Manila by company vehicle. No unsupervised third parties were given access prior to the chain of custody procedure. o Samples were delivered to Intertek Testing Services along with two copies of the sample dispatch form. One copy for the laboratory to accept custody of the sample, and the signed/received copy return to database custodian at the Core House facility in Tabuk, Kalinga. |

Audits or reviews | · The results of any audits or reviews of sampling techniques and data. | · No other specific audit or review was conducted other than the validation checks by the author documented earlier with regard to the sample preparation, analysis or security for the information in the new drillholes. |

SECTION 2:

Reporting of Exploration Results(Criteria listed in the preceding section also apply to this section.)

Criteria | JORC Code Explanation | Commentary |

Mineral tenement and land tenure status | · Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. · The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. | · The Maalinao-Caigutan-Biyog (MCB) Copper-Gold project is situated in Luzon Central Cordillera in the Barangay of Balatoc, Municipality of Pasil, Province of Kalinga. · The Project is covered by Mineral Production Sharing Agreement MPSA-356-2024-CAR, which encompasses approximately 2,501 hectares and was granted on 14 March 2024. · The tenement is held by Makilala Mining Company Inc. (MMCI), a Philippines registered corporation that is 100% owned by Makilala Holdings Ltd, · The Project site is located within the Ancestral Domain of Balatoc, and Free and Prior Informed Consent (FPIC) has been secured from the Balatoc tribe for development and operation of the mine within the designated tenement area. · The MPSA grants exclusive rights for exploration, development, and commercial production of copper and associated minerals for 25 years, renewable for another 25 years, providing secure tenure for the Project. · The MCB Project has obtained all National Government statutory permits to commence development and mining operations, · |

Exploration done by other parties | · Acknowledgment and appraisal of exploration by other parties. | · Exploration work and drilling was completed by Makilala Mining Company Inc. from year 2006 to 2025, the details of which have been documented in CLA announcements. · The relative quality and detail associated with the drilling information is considered to be of a high standard. This has enabled the author to establish a high level of confidence associated with the historical drilling information. |

Geology | · Deposit type, geological setting and style of mineralisation. | · The geological setting for the MCB copper-gold mineralisation is typical of a porphyry copper + gold + moly deposit as commonly defined in many academic papers (Hedenquist and Lowernstern, 1994; Sillitoe, R. H., 2010. Corbett and Leach, 1997). The mineralisation and associated alteration exist across the contact between the genetically related intrusive body (tonalite) and the surrounding host rock material. In most cases the surrounding host rock is a mafic volcanic, however, in some instances the older (not genetically related to copper-gold mineralisation) intrusive bodies also exist in contact with the younger intrusive resulting in broad sections of mineralisation and alteration within a series of intrusive bodies. · There is also evidence at MCB for epithermal vein deposit types which exist within close proximity to the large-scale porphyry copper-gold mineralisation. At this stage, only the deposit type that is identified from the drilling information for MCB is a porphyry copper-gold style. · Basalt lava flows make up the majority of the host rocks in the tenement area, which is part of the oldest exposed unit, Basement Complex. This Cretaceous-Paleogene Metavolcanics has been intruded by quartz diorite complex, which in Kalinga, ranges in composition from gabbro to tonalite. · A later stage Tonalite intrusion exists throughout the project area and is interpreted to be genetically related to the copper-gold mineralisation at MCB deposit. · A dacite flow and dacitic pyroclastic blankets the older basalt host rock and tonalitic intrusive rocks. · There are four types of ore mineralisation that were emphasized in the project: o Type 1 - Early high-grade porphyry Cu-Au mineralisation, hosted both in tonalite and basalt. o Type 2 - Mix of high-grade porphyry Cu-Au (Type 1) and high-sulphidation mineralisation (Type 4). Hosted in basalt and tonalites, but with strong Type 1 mineralisation that was partially overprinted by ore Type 4. o Type 3 - Medium grade porphyry-copper o Type 4 - High-sulphidation epithermal mineralisation · (See and for a representative Cross Section of the Geology and its relationship to the copper-gold mineralisation at the MCB Deposit). |

Drill hole Information | · A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes: · easting and northing of the drill hole collar · elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar · dip and azimuth of the hole · down hole length and interception depth · hole length. · If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case. | · See Section 1 (Sampling Techniques and Data) for all details regarding the drill hole information for the MCB Property in addition to a full list of all significant drill intersections which have been reported. · In addition to the drilling information that has been reported from previous MRE, 5 new drill holes were completed by MMCI and included as part of this updated Mineral Resource estimate for MCB. · In summary the drill hole database used for the updated MCB MRE consists of 64 diamond drill holes with an accumulated meterage of 31,616.20. · No drill hole information has been excluded. |

Data aggregation methods | · In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated. · Where aggregate intercepts incorporate short lengths of high-grade results and longer lengths of low-grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. · The assumptions used for any reporting of metal equivalent values should be clearly stated. | · No exploration results are reported in this release. · Only individual weighted average assay results have been reported and no metal equivalent values have been reported. |

Relationship between mineralisation widths and intercept lengths | · These relationships are particularly important in the reporting of Exploration Results. · If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. · If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg 'down hole length, true width not known'). | · There are several drilling orientations, but generally drill holes were designed in a rough grid pattern on lines oriented N30W-S30E spaced at 100 to 200 meters apart, with an inclination of -60 degrees. For the drilling which is at an angle of -60 degrees, there is a relative angle against the contact of the near to vertical intrusive Tonalite and associated copper-gold mineralisation of approximately 30 degrees. In this case, the estimated true widths of the copper-gold mineralisation is approximately half of the reported down hole length. · In some instances, there are vertical drill holes which are still useful in defining the extent of the copper-gold mineralisation, but at a relatively poor angle to define the distribution of the copper-gold mineralisation due to being sub-parallel to the mineralisation direction. · Recent drilling completed by MMCI has improved the distribution of assay information over the central portion of the defined copper mineralisation to improve confidence in the continuity and for the purpose of increasing the category from Indicated to Measured at some important locations. |

Diagrams | · Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include but not be limited to a plan view of drill hole collar locations and appropriate sectional views. | · See Figure 4 and Figure 5 for representative Cross Section of the Geology and its relationship to the copper-gold mineralisation at MCB. |

Balanced reporting | · Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. | · All data for the project has been collected, validated and reported and is considered to be a fair representation of the MRE from MCB which is the subject of this which is the subject of this release. |

Other substantive exploration data | · Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. | · Historical exploration since the date of the original grant of EP-003-2006-CAR in 2006 was undertaken under the ownership and management of Makilala Mining Company Inc. Exploration work conducted by Makilala Mining Company Inc include surface mapping and sampling (2007), ground magnetic survey (2007), induced polarisation (IP) geophysical surveys (2010), and an extended period of diamond drilling from 2006 through to 2025 for a total of 46 diamond drill holes. |

Further work | · The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling). · Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. | · There are a few locations where the potential extension to the current Minerals Resource could be tested. These locations are initially defined at depth plunging steeply to the west underneath the high-grade copper-gold mineralisation, and also to the west of the Maalinao-Panyaw fault. The location for the possible high-grade copper-gold to the west include at depth, due to the interpretation that the fault has downthrown the geology on its western side, or toward the north-west, as a possible trend exists to the mineralisation in this direction which has not been tested. · Apart from the direct extensions to the currently defined copper-gold mineralisation, there is considerable scope for further discoveries of two defined deposit types at the MCB Tenement. · Porphyry copper-gold deposit types o There are extensive intrusions in the area that are directly related to the copper-gold mineralisation, and which could at multiple locations formed significant high-grade copper-gold deposits. · Epithermal vein hosted deposit types o It is considered likely that there could be a combination of narrow high grade, and/or more broad large scale and lower grade epithermal deposit types that are closely related to the porphyry copper-gold deposits at MCB. |

SECTION 3:

Estimation and Reporting of Mineral Resources(Criteria listed in section 1, and where relevant in section 2, also apply to this section.)

Criteria | JORC Code Explanation | Commentary | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Database integrity | · Measures taken to ensure that data has not been corrupted by, for example, transcription or keying errors, between its initial collection and its use for Mineral Resource estimation purposes. Data validation procedures used. | · The original assay sheets and drill logs were checked against the drill hole database by the author and no systematic or random errors were identified as part of this validation check of the database. · In addition, the original laboratory reports were checked against the drill hole database. This data review did not identify any systematic or isolated errors in the drill hole database. · Outliers in the specific gravity measurements were excluded from the dataset. · Drill core observations and validation steps were completed in August 2020 which included a review of all the defined Ore Domains and broad contact positions between the high grade and low-grade domains in addition to the low-grade ore to waste domain boundaries. · All drill core from the MCB Project which were used to define the 2025 Mineral Resources have been preserved and were available for the author to visually check against the drill logs and recorded assay results. · Geological observations that are recorded in the drill logs leading to the definition of the mineralised domains at MCB appear consistent and reflective of what could be observed from the drill core by the Author. In addition, copper sulphides and recently weathered copper-sulphides (due to exposure of the drill core at the surface) are observable in the drill core where high grade copper mineralisation has been reported. The relative presence of copper sulphides and oxidised copper minerals appear reasonably reflective of the assay results reported in the database based on the observations made by the author of the drill core. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Site visits | · Comment on any site visits undertaken by the Competent Person and the outcome of those visits. · If no site visits have been undertaken indicate why this is the case. | · The Author has completed site inspections of the property including detailed review of the drill core which relate to the Mineral Resource Estimate. The field inspections included validation of the drill collar locations for drill holes (using a handheld GPS) which contained significant copper mineralisation that are included in the Mineral Resource estimate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Geological interpretation | · Confidence in (or conversely, the uncertainty of) the geological interpretation of the mineral deposit. · Nature of the data used and of any assumptions made. · The effect, if any, of alternative interpretations on Mineral Resource estimation. · The use of geology in guiding and controlling Mineral Resource estimation. · The factors affecting continuity both of grade and geology. | · The geological interpretation associated with the MCB Mineral Resource estimate is considered by the author to have a high level of confidence, with limited variability considered likely due to a difference in the geological interpretation. · The interpretation and Mineral Resource estimate have been compared directly with the previous Mineral Resource estimate in 2022. The copper and gold mineralization defined in the Mineral Resource estimate has a high level of consistency relative to the geological interpretation completed by Freeport-McMoRan. · The geological controls on the copper-gold mineralization at the MCB copper-gold mineralisation is typical of a porphyry copper + gold + moly deposit as commonly defined in many academic papers (Hedenquist and Lowernstern, 1994; Sillitoe, R. H., 2010. Corbett and Leach, 1997). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dimensions | · The extent and variability of the Mineral Resource expressed as length (along strike or otherwise), plan width, and depth below surface to the upper and lower limits of the Mineral Resource. | · The copper-gold mineralisation at MCB is typical for a porphyry copper-gold deposit with the geometry of a very thick body, up to 100m in true width for the high-grade core and surrounded by over 400m in true width of additional lower grade copper mineralisation, as a relatively elongate body which stretches out parallel to the contact between the intrusive tonalite and the host rock basaltic rocks. · Away from the central core, the high-grade copper-gold mineralisation extends further as a narrow structurally controlled sheet, interpreted again to be mostly parallel to the tonalite - basalt contact, with some possible extensions extending along interpreted structures which exist in a north-north-west orientation. Both structural sets are close to vertical, and their intersection points also are very steeply dipping | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Estimation and modelling techniques | · The nature and appropriateness of the estimation technique(s) applied and key assumptions, including treatment of extreme grade values, domaining, interpolation parameters and maximum distance of extrapolation from data points. If a computer assisted estimation method was chosen include a description of computer software and parameters used. · The availability of check estimates, previous estimates and/or mine production records and whether the Mineral Resource estimate takes appropriate account of such data. · The assumptions made regarding recovery of by-products. · Estimation of deleterious elements or other non-grade variables of economic significance (eg sulphur for acid mine drainage characterisation). · In the case of block model interpolation, the block size in relation to the average sample spacing and the search employed. · Any assumptions behind modelling of selective mining units. · Any assumptions about correlation between variables. · Description of how the geological interpretation was used to control the resource estimates. · Discussion of basis for using or not using grade cutting or capping. · The process of validation, the checking process used, the comparison of model data to drill hole data, and use of reconciliation data if available. | · The MCB geological models, ore domain models and associated interpolation were all completed in the 3D software modelling package Leapfrog Geo and Leapfrog Edge (Version 2025.1.1). · Ore Domains o A combination of features was utilized to review and subsequently domain the copper mineralisation to an appropriate level for the purpose of estimating the copper and gold contents. · High Grade Copper Domain (s) o A high-grade ore type called "Ore Type 1" was based on alteration features, magnetic susceptibility readings and copper grades. o In addition, the spatial location of this ore type was predominantly situated across a tonalite and mafic volcanic contact position. o For the purpose of defining an ore domain that obeyed the observed trends and geological controls on the mineralisation, the Type 1 ore positions were reviewed relative to the potential continuity of this ore type. o In locations where this ore type was very narrow, or patchy and no observable continuity, this ore type was not defined as a Type 1HG domain. o In positions where the larger and more continuous Type 1 sections were observed, the ore domain was further reviewed for possible continuity along the trend of the tonalite/mafic volcanic contact position. In some cases, the Type 1HG domain was extended into a larger body, where there appeared to be additional high-grade copper mineralisation that extended as part of this mineralized domain in 3D space along the tonalite/mafic contact position. o The original Type 1HG high-grade domain has been divided into two separate domains. The Type 1HG domain was segregated into a shallow horizontal high-grade domain (Type 1 HGH) representing shallow and relatively flat-lying higher grade copper mineralisation, and the remaining vertically oriented high-grade material which forms the Type 1 HGV (High Grade Vertical) domain. Both domains are predominantly characterized by Type 1 style mineralisation. · Low Grade Copper Domain o Further grade continuity models were created surrounding the high-grade material, with observable boundaries which are parallel to the older volcanics and diorite intrusions position. o There appear to be a natural geological boundary at close to 0.2% copper, which has been used as the basis for developing a surrounding low-grade domain which is substantially mineralized. The position for copper mineralisation is not necessarily at exactly 0.2% copper, however, it is observable that there are distinct trends with grade distributions roughly above and then below into waste domains across this position. For example, there is a distinct low-grade trend in the middle of the tonalite body which is parallel to the dip and strike of the main structural trend. This observation and apparent close link to the grade trends with the geological contacts and alteration was the basis for creating a low-grade domain which ensured that the data from the waste material was not mixed with the broader lower grade trends as part of the Mineral Resource estimate o Therefore, a low-grade domain boundary was created which obeyed the general trend of the contact position between assay results which were above and below 0.2% copper and for which this contact position was distinctly parallel to the dominant geological trends. · BLOCK SIZE o A parent cell size of 10m x 10m x 10m was used as the final model block size which appear to appropriately fill the model with cells and is considered appropriate for any potential economic evaluation of the Mineral Resource, which is most likely considered to be via the block caving method, or large-scale open stoping mining with back fill. · ORE CONTINUITY AND STATISTICAL ANALYSIS o After applying the constraints on the ore domains for the high-grade and low-grade domain boundaries, each dataset was reviewed in terms of their basic statistics and also a review of their potential continuity based on their variograms. · STATISTICS AND TOP CUT o The summary basic statistical information for copper, gold and specific gravity associated with each domain, based on the 2-meters composited datasets from within each domain are summarised in the following tables. o A review of the statistics for each domain did not identify significant high value outliers that are considered likely to result in an overestimated either locally or globally to the grade distribution within the block model. Therefore, no top cut was applied to the Mineral Resource estimate.

· VARIOGRAM ANALYSIS o Variograms were completed for all of the reported mineralised domains. The results were generally in line with the geological interpretations with a high level of confidence up to in initial structure or inflection point in the variogram between 50m and 70m for all three mineralised domains. This distance when supported by multiple drill holes is considered to have a high degree of confidence with regards to the copper and gold grade estimates based on the observations of the copper grade information in 3D space relative to the host rock geology and influencing or cross cutting major faults. o The Sill for the variograms for each mineralised domains extended further, but at a lower level of confidence than the initial structure defined within each variogram. Details for each mineralised domain are summarised below. · Type 1HGV Domain: This ore domain occurs as a vertical high-grade copper mineralisation situated across a tonalite and mafic volcanic contact position. The major axis has a strike of 050 degrees which is very close to the observable trend of the geology and interpreted boundaries to the copper mineralisation. · Type 1HGH Domain: This ore domain occurs as a shallow and relatively flat lying higher grade copper mineralization. The variogram analysis has strong support for over 60m, up to an inflection point where the sill in modelled. · Type 3LG Domain: A distinct low-grade trend in the middle of the tonalite body and surrounding the higher-grade mineralisation domains within the host rock mafic rocks which is parallel to the dip and strike of the main structural trend. · INTERPOLATION METHOD o After definition of the ore domains and subsequent statistical and variogram analysis were completed for each ore domain, Ordinary Kriging (OK) was used as a standard estimator for both copper and gold values. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Moisture | · Whether the tonnages are estimated on a dry basis or with natural moisture, and the method of determination of the moisture content. | · The tonnes estimated for the MCB deposit block models were calculated on a dry basis. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cut-off parameters | · The basis of the adopted cut-off grade(s) or quality parameters applied. | · The MCB deposit has been limited to a defined body of copper and gold mineralisation which are predominantly above 0.2% copper on average. · The 0.2% lower limit is also broadly in line with the expected lower economic limits of the likely mining and processing options considered for MCB. · Therefore, a preferred lower cut-off grade of 0.2% copper was applied to the reporting of the Mineral Resource estimate which is based on the information provided in this report (Table 1). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mining factors or assumptions | · Assumptions made regarding possible mining methods, minimum mining dimensions and internal (or, if applicable, external) mining dilution. It is always necessary as part of the process of determining reasonable prospects for eventual economic extraction to consider potential mining methods, but the assumptions made regarding mining methods and parameters when estimating Mineral Resources may not always be rigorous. Where this is the case, this should be reported with an explanation of the basis of the mining assumptions made. | · Benchmark mining costs of US$16/ t and processing costs of US$10/t respectively for a medium sized (2.25Mt per annum) underground block caving mining method and processing using floatation to produce a copper-gold concentrate have been assumed where applicable for the Mineral Resource estimate. · A lower cut-off grade of between 0.2% and .25copper has been used as the preferred lower cut-off grade for the reported Mineral Resource estimate, which is considered appropriate based on the geological continuity associated with copper mineralisation above 0.2% copper in addition to a broad economic cut-off point based on a US$5/lb copper price. · A preliminary economic assessment ( Study - see CLA announcement on 1 December 2021) was completed for the MCB deposit which identified that an initial mining method of sub-level open stoping with back-fill would be the preferred mining method. The closest approximation with regards to a lower cut-off grade for this type of mining method is close to 0.5% copper, similar to the defined boundaries of the high-grade mineralised domains. · A review is also ongoing with regards to some surface at stabilisation work and block caving mining methods, both of which are considered to identified mining options which would have economic cut-off closer to the reported Mineral Resource of 0.2% copper. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metallurgical factors or assumptions | · The basis for assumptions or predictions regarding metallurgical amenability. It is always necessary as part of the process of determining reasonable prospects for eventual economic extraction to consider potential metallurgical methods, but the assumptions regarding metallurgical treatment processes and parameters made when reporting Mineral Resources may not always be rigorous. Where this is the case, this should be reported with an explanation of the basis of the metallurgical assumptions made. | · Test work for the multiple mineralisation types over various grade ranges have been completed at both ALS laboratory in Perth and Brisbane Met Labs. The results from this test work identified that high copper and gold recoveries (95% and 77% respectively) are possible from the MCB copper mineralisation using conventional floatation technology to recover a saleable copper-gold concentrate (See CLA announcement dated 11 November 2025). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Environ-mental factors or assumptions | · Assumptions made regarding possible waste and process residue disposal options. It is always necessary as part of the process of determining reasonable prospects for eventual economic extraction to consider the potential environmental impacts of the mining and processing operation. While at this stage the determination of potential environmental impacts, particularly for a greenfields project, may not always be well advanced, the status of early consideration of these potential environmental impacts should be reported. Where these aspects have not been considered this should be reported with an explanation of the environmental assumptions made. | · The MCB deposit exists within a relatively high mountain range with local regions containing high topographic relief, ranging from 800m in the valleys to over 1,300m at the surrounding mountain peaks. · Work completed as part of the study announced by CLA on 1 December 2021 identified a number of mining options which are considered viable options for the mining of the MCB deposit which take into account the environmentally sensitive nature of the high mountain range and local environment at MCB. · It is assumed at this stage that there are no additional impediments or environmental controls which would prevent the proposed mining operation from proceeding outside of the assumptions made in this release. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bulk Density | · Whether assumed or determined. If assumed, the basis for the assumptions. If determined, the method used, whether wet or dry, the frequency of the measurements, the nature, size and representativeness of the samples. · The bulk density for bulk material must have been measured by methods that adequately account for void spaces (vugs, porosity, etc), moisture and differences between rock and alteration zones within the deposit. · Discuss assumptions for bulk density estimates used in the evaluation process of the different materials. | · Bulk density measurements were routinely taken throughout the drilling campaign and are available for all the defined ore domains. The method used to collect the specific gravity information for each drill hole is summarised in the sampling and core management procedures report by by the company. These procedures are summarised as follows: o Specific gravity is determined by weighing a dry core sample in air and as submerge in water. o Two 10 to 15 cm long split core samples are collected from each sampling interval, one near the start and the other near the end of the interval. o Samples were weighed in air, weighed suspended in water, and weighed in air again to determine its saturated weight. · A review of the bulk density measurements identified that there is minimal variability in the bulk density measurements, apart from some generally lower values that exist closer to the surface, or within the top 100m from surface. · Given that the basic statistics for specific gravity in each domain showed very low standard deviation for both uncomposited and 2m composited drill hole data, the mean specific gravity value for each domain was applied as the default throughout the respective block model domains. These default values were derived from the basic statistics of the drill hole data for each ore domain. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Classification | · The basis for the classification of the Mineral Resources into varying confidence categories. · Whether appropriate account has been taken of all relevant factors (ie relative confidence in tonnage/grade estimations, reliability of input data, confidence in continuity of geology and metal values, quality, quantity and distribution of the data). · Whether the result appropriately reflects the Competent Person's view of the deposit. | · Measured Mineral Resource Classification o The updated Mineral Resource for MCB increased the confidence on the Measured component of the 2025 Mineral Resource Estimate. The criteria for the Measured Mineral Resource for each domain was based on search ellipse parameters with a maximum direction length of 60m which was less than 60% of the defined Sill distance for all the mineralised domains and corresponded to an inflection point in the variogram within which the confidence level for the continuity of the copper distribution is higher. Minimum selection criteria for the Measured criteria also included a minimum of 8 samples from at least 2 drill holes and a maximum total of 18 samples derived from the 2m composited data. · Indicated Mineral Resource Classification o The Indicated Resource for the MCB model was based on the second pass which was defined by a search distance which is approximately the ~1.5x the Sill distance based off the Variogram analysis for each domain. The additional selection criteria for the Indicated category included minimum number of samples of 4 and a maximum of 20 samples derived from the 2m composited data. · Inferred Mineral Resource Classification o The Inferred Mineral Resource was extended for twice the distances applied to the Indicated Mineral Resource using a minimum of 2 samples and maximum of 10 samples defined for each block. Samples derived from only 1 drill hole were required to fill the blocks for the Inferred category. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Audits or reviews | · The results of any audits or reviews of Mineral Resource estimates. | · No independent audit or review has been undertaken on the updated Mineral Resource estimate for the MCB Project which is the subject of this JORC Report. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||