9th Feb 2026 07:00

THIS ANNOUNCEMENT CONTAINS INSIDE INFORMATION FOR THE PURPOSES OF ARTICLE 7 OF EU REGULATION 596/2014 (WHICH FORMS PART OF DOMESTIC UK LAW PURSUANT TO THE EUROPEAN UNION (WITHDRAWAL) ACT 2018) ("UK MAR").

Fulcrum Metals plc / EPIC: FMET / Market: AIM / Sector: Mining

9 February 2026

Fulcrum Metals plc

("Fulcrum" or the "Company" or the "Group")

Fulcrum reports 31% higher gold recovery and co-product recoveries at the Teck Hughes Tailings Project

Fulcrum Metals plc (AIM: FMET), a company pioneering the application of innovative cyanide-free technologies to recover precious and critical metals from mine waste, is pleased announce o provide an update on Phase 3 optimisation trials undertaken by Extrakt Process Solutions, LLC. ("Extrakt") and Testing Design Implement Solutions LLC ("TDI") at its 100% owned Teck Hughes tailings project in Kirkland Lake, Ontario. Extrakt technology is now delivering 78% gold recovery, a 31% increase over Phase 1, with multiple co-products recovered from a single stage in situ process.

Highlights

· Gold recovery of up to 78% - a 31% increase from Phase 1 testing

· Recovery of multiple co-products including up to 95% silver, 96% tellurium, 85% copper and 20% gallium

· Indicative in-situ metal value of approximately US$750 million, with a conceptual potential recoverable value of over US$550 million, based on recovery test work, revised metal prices, auger hole results and estimated tonnage (Figure 3) (These figures are conceptual in nature and do not constitute Mineral Resource or Reserves)

· Further optimisation work is needed to improve gallium recovery and additional potentially valuable minerals recovery that remain untested

· Phase 3 Test results support a technically robust pathway to improved gold recovery, solution management, and tailings handling: -

o Optimised leaching cycle time of just 6 hours, supporting high throughput

o Rapid dewatering times of less than 1 minute, producing approximately 80% dry stack material which may reduce handling costs

o Operating cost efficiencies with approximately 80% of water and reagents recovered for reuse, reducing demands on downstream equipment

o Extrakt Reagent Management System ("ERMS") test work indicates the potential for significant benefits, reducing process solution volume by about 80% while increasing precious metal concentrations by 85-90%

· The Company is assessing the next step of optimisation and commercialisation through larger scale and pilot scale testing subject to technical review

Ryan Mee, Chief Executive Officer of Fulcrum, commented:

"The Extrakt technology has delivered results which significantly upgrades the economic potential of our Teck Hughes project and supports effective site rehabilitation.

The results from Fulcrum and Extrakt's work programmes validate Extrakt's technology as an emerging disruptive Zero-Cyanide Zero-Waste, closed loop tailing recovery process. Fast and high co-product metal recoveries from a single stage leach configuration, a rapid dewatering process recovering water and reagent and the EMRS reducing solution volume all have positive implications for both the mining industry and the environment.

We are in discussions with Extrakt on further steps to optimise recoveries and monetise a wider range of co-products. I will keep investors updated on further developments."

PHASE 3 OPTIMISATION AND DEVELOPMENT

Background

Extrakt has developed its proprietary environmentally friendly cyanide-free TNSTM technology for enhanced leaching and recovery of gold and other metals from all types of ores and solid-liquid separation that significantly improves dewatering and consolidation of mine tailings. Fulcrum is further evaluating the applicability of this technology for its Teck-Hughes tailings project at Kirkland Lake Ontario, Canada following the successful completion of the Phase 1 high level gold leach recovery and Phase 2 high level concept study.

Fulcrum engaged Extrakt to conduct a Phase 3 high-level technical assessment to determine optimal leaching and dewatering conditions through controlled laboratory testing. The assessment was to provide further optimisation of a single stage leach and configuration process. The leach recovery test work for the recovery of gold, silver, and a select group of metals has been extended to include tellurium and gallium, which were not included in the first stage.

Leaching

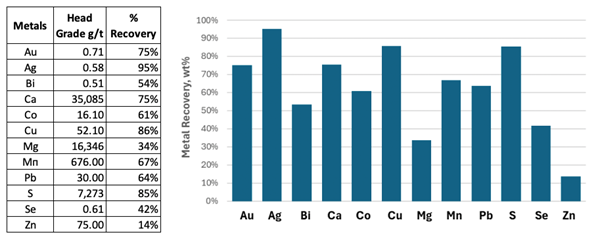

Step 1: Optimised leach results for select material at 54 microns and 38 degrees

Gold recovery improves with reduced P80 particle sizeto 54 microns requiring only 10 minutes of grind time. Temperature adjustments demonstrated a positive correlation with recovery, with 38 degrees balancing economic benefits of recovery and enhanced temperature, but further work is required to determine the optimum level. Extending leach times from 6 hours to 9.5 hours did not result in a meaningful increase in recoveries, confirming that 6 hours is optimal. While gold was the primary target other minerals also demonstrated significant and moderate co-extraction of metals providing valuable insight into mineral deportment and selective metal mobility under the applied conditions.

Figure 1: Optimised leaching results for select material at 54 microns and 38 degrees

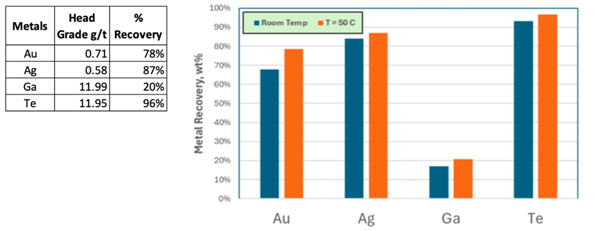

Step 2: Effect of leaching temperature on Gold, Silver, Tellurium and Gallium recovery at 54 Microns

The extended testing program from step 1 demonstrated co-extraction of selected metals. Increasing leaching temperature consistently improved recoveries of all metals. Gallium demonstrated a very different behaviour and deportment which requires further testing and adjustments to leaching chemistry and configuration.

Figure 2: Effect of leaching temperature on Gold, Silver, Tellurium and Gallium recovery at 54 Microns

Dewatering and Filtration

Vacuum filtration combined with Extrakt TNSTM dewatering reagent, consistently produced fast cycle times of less than 1-minute, high cake solids and low residual moisture. The method is technically effective and operationally simple, enabling efficient recovery of pregnant solutions.

From a process perspective, these outcomes have several important implications. Reducing solution volume decreases downstream equipment loading and reagent demand in the precipitation circuit, while increasing precious metal concentration enhances recovery efficiency and operational robustness. Collectively, these effects support improved mass-balance control, lower operating costs, and more efficient integration of the recovery circuit within a closed-loop ERMS.

Extrakt Reagent Management System

Process simulation indicates that ERMS could reduce solution volume to precipitation by approximately 80% while increasing concentration to approximately 85-90%. The modelled outcomes suggest significant potential benefits, although validation through larger scale and pilot scale testing is required.

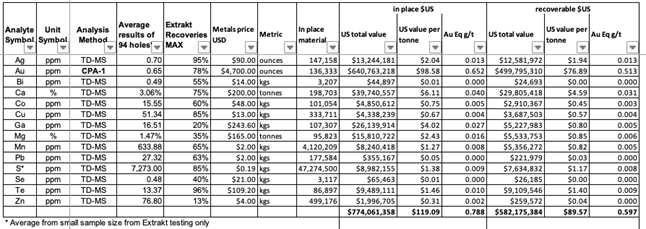

Teck Hughes potential in situ and extractable values

Based on an estimated 6.5 million tonnes in situ (to be confirmed by Fulcrum), the average grades reported from 94 complete auger holes, and the price per Ounce/Kg/Tonne of material as outlined, the in situ value would be in the region of US$750m. Based on the extraction rates from Phase 3 testing and development work with Extrakt, the recoverable value could be in the region of US$550m. Further testing, validation, and potential leaching and configuration adjustments are required, and market accessibility for the product is to be confirmed.

Additional critical and other minerals may be in high enough concentration to derive additional economic value, subject to a review of available information and discussion with Extrakt about potential testing and development steps.

Figure 3: Metals concentration and extraction rates from Phase 3 testing

The above table uses US$ metal prices around the time of this news release. Metal prices are subject to market pricing and fluctuations.

FULCRUM'S PROJECTS AND COMMERCIAL PATHWAY

Fulcrums Projects

Fulcrum's Teck Hughes and Sylvanite tailing projects are just 3km apart and based in Kirkland Lake, Ontario, Canada. Fulcrum are leading with development towards production at the Teck Hughes project with synergy opportunities to expand operations to integrate the Sylvanite project to develop a regional processing hub.

Zero Cyanide Zero Waste Approach

Fulcrum is using Extrakt's proprietary TNSTM cyanide free leaching and solid-liquid separation technologies in a closed loop system to achieve a Zero Cyanide Zero Waste solution for effective mine tailings reprocessing and site remediation.

Advancing the Projects

Workstreams of auger drilling and testing development work with Extrakt, including initial high-level testing, conceptual studies, technology optimisation, and economic assessment studies, will provide the basis for a 43-101 compliant MRE leading to commercialisation steps through to production.

Fulcrum will then be positioned to scale the concept across other legacy sites, particularly across two of Canada's historically most productive gold regions, Timmins and Kirkland Lake, through its Exclusivity with Extrakt. Fulcrum believes this is a long-term opportunity to unlock significant and largely untapped value from legacy mine waste.

Auger Drilling

Fulcrum has completed a 159-hole auger drill program to provide the detailed mineralogical data needed to support a Mineral Resource Estimate ("MRE"). Photon gold and ICP-MS Ultratrace 4 multi-element results have been returned for 94 augur drill holes to date. Incorporating gold, silver, tellurium and gallium only, resulted in a notable 8% increase in gold-equivalent grade ("AuEq") to 0.701 g/t Au (see Fulcrum news release 27 January 2026). The best gold equivalent assay results are 1.68g/t AuEq over 0.8 metres, best hole results of 1.08g/t AuEq over 4.75 metres from surface and the deepest hole measured is 12.4 metres.

Final samples for the remaining 65 auger holes are presently at Actlab for comparative Gold Fire Assay and ICP-MS Ultratrace 4 multi-element assay.

Phase 1 testing and Phase 2 Early Concept

Fulcrum completed successful phase 1 bench testing for gold leach recovery only, and a phase 2 early non-optimised conceptual study at Teck-Hughes. The study conceptualised a simple single-stage leach and dewatering process in a closed-loop system. This was based on an estimated 6.5 million tonnes in-situ (to be confirmed by Fulcrum), 2,000 tonnes of tailings processed per day over a 9-year mine life, a 59.4% gold recovery rate, a 6-hour leach time, and a gold price of US$2,899/oz suggesting a pre-tax Net Present Value at a 7.5% discount ("NPV7.5") of approximately US$33m with a 3 year payback period (see announcement released by Fulcrum on 12 March 2025).

A sensitivity analysis suggests that a 25% increase in the recovery rates or in the gold price each increases the pre-tax NPV7.5 by 129% to US$75.5m, reducing the payback period to less than 2 years with an Internal Rate of Return of 37.75%.

Phase 3 Optimisation

Laboratory-based test work with Extrakt using their proprietary cyanide-free leach and solid-liquid separation TNSTM technologies was completed in February 2026 (see announcement by Fulcrum on 8 February 2026). The test work focused on a simple single-stage leach and configuration to extract metals and dewater tailings in a closed-loop system for effective site remediation. The leach results reported fast optimised cycle times of 6 hours, a substantial increase in gold recoveries of up to 78% gold, and potential additional co-product recoveries including up to 95% silver, 96% tellurium, 85% copper and 20% gallium. The solid-liquid separation confirmed an effective closed loop process with fast dewatering times of less than 1 minute, producing 80% dry stack material for site remediation, and cost reductions with 80% recovery of water and reagent for reuse and reduced demand on downstream equipment.

With gold now above US$4,900/oz (as at 5 February 2026) and results from the Extrakt phase 3 test and development work completed, both have significantly enhanced the economic potential of the Teck Hughes project.

Next steps

Fulcrum is in discussions with Extrakt on further steps to optimise recoveries and to monetise a wider range of co-products and commercialisation steps through larger scale and pilot scale testing.

Technical Glossary

Ag | Silver |

Au | Gold

|

AuEq | Gold equivalent grade

|

Ga | Gallium |

g/t | grams per metric tonne

|

CPA-AU1 | Gamma-ray analysis of sample for gold by Photon Assay instrument

|

Fire Assay | An assay procedure involving heating the sample in a furnace to ensure complete extraction of all the contained precious metal

|

ICP Analysis | Inductively Coupled Plasma - an analytical technique that can be used to measure elements at trace levels

|

ICP-MS Ultratrace 4 | Four acid near-total sample digestion followed by ICP-MS multi-element analysis |

PFS | Pre-Feasibility Study |

P80 | Material passing through an 80-mesh sieve |

S | Sulphur |

Te | Tellurium |

Qualified Person Statement

The technical information in this announcement has been reviewed by Edward (Ed) Slowey, BSc, PGeo, technical advisor to Fulcrum Metals Plc. Mr Slowey is a graduate geologist with more than 40 years' relevant experience in mineral exploration and mining and a founder member of the Institute of Geologists of Ireland. Mr Slowey has sufficient experience relevant to the style of mineralisation and type of deposit under consideration and to the activity which has been undertaken to qualify as a "Qualified Person" in accordance with the AIM Rules Guidance Note for Mining and Oil & Gas Companies. Mr Slowey consents to the inclusion in the announcement of the matters based on their information in the form and context in which it appears.

FOR FURTHER INFORMATION

Visit: www.fulcrummetals.com

Follow on X: @FulcrumMetals

Contact:

Fulcrum Metals PLC | |

Ryan Mee (Chief Executive Officer) | Via St Brides Partners Limited |

Allenby Capital Limited (Nominated adviser) | |

Nick Athanas / Ashur Joseph | Tel: +44 (0) 203 328 5656 |

Clear Capital Markets Limited (Broker) | |

Bob Roberts | Tel: +44 (0) 203 869 6081 |

St Brides Partners Ltd (Financial PR) | |

Ana Ribeiro / Paul Dulieu | Tel: +44 (0) 20 7236 1177 |

Notes to Editors

About Fulcrum Metals PLC

Fulcrum Metals PLC (AIM: FMET) is an AIM listed technology led natural resources company focused on recovery of precious metals from mine tailings (previously milled and processed ore) in Canada using environmentally friendly leaching technology developed by Extrakt Process Solutions LLC and its associates (together "Extrakt"). The Company's current projects are the tailing sites of the former Teck-Hughes and Sylvanite gold mines, located in the Kirkland Lake region of Ontario. In addition, the Company has interests in a portfolio of highly prospective mineral exploration and development projects in both Ontario and Saskatchewan Canada.

Fulcrum has exclusive rights to use Extrakt's proven cyanide-free technology on gold mine waste sites over the mining districts of Timmins and Kirkland Lake. These are two of Canada's biggest gold camps with a historical production above 110Moz over the past 100 years, leaving more than 70 documented legacy mine waste sites.

Fulcrum is now focused on the development of its Teck-Hughes and Sylvanite projects towards optimisation and production using Extrakt's technology and positioned to scale the concept across two of Canada's historically most productive gold regions. Fulcrum believes this represents a substantial, long-term opportunity to unlock significant and largely untapped value from legacy mine waste.

Related Shares:

Fulcrum Metals PLC