13th Oct 2025 07:00

The information contained within this announcement is deemed by the Company to constitute inside information as stipulated under the Market Abuse Regulations (EU) No. 596/2014 ('MAR') which has been incorporated into UK law by the European Union (Withdrawal) Act 2018.

13 October 2025

Strategic Minerals plc

("Strategic Minerals" or the "Company")

Redmoor - Exceptional Tungsten Drilling Results

Multiple mineralised intervals identified reinforcing Redmoor's status as one of the highest-grade undeveloped tungsten deposits globally

Strategic Minerals plc (AIM: SML; USOTC: SMCDF), an international mineral exploration and production company, is delighted to announce that its wholly owned subsidiary, Cornwall Resources Limited ("CRL"), has received standout drillhole assay results from the ongoing drilling campaign at its Redmoor tungsten-tin-copper project located in Cornwall, UK.

Highlights:

Laboratory assay results for borehole CRD033, the first of the 2025 drilling programme, confirm multiple zones of high-grade tungsten mineralisation throughout the full 90 m thickness of the Redmoor Sheeted Vein System ("SVS") deposit intercepted by the borehole (see Table 2 for sample intersection details) with highlights including:

· 3.05 m @ 1.43% WO3 & 0.54% Cu from 439.70 m, including:

o 1.30 m @ 2.34% WO3 & 0.44% Cu from 439.70 m, and

o 0.75 m @ 1.54% WO3 & 0.68% Cu from 442.00 m

· 6.70 m @1.17 WO3 & 0.24% Cu from 447.00 m, including:

o 2.00 m @ 3.86% WO3 & 0.54% Cu from 451.20 m

· 9.35 m @ 0.51% WO3 & 0.48% Cu from 468.65 m, including:

o 1.00 m @ 1.42% Cu, 0.06% WO3 & 38.2 g/t Ag from 469.65 m, and

o 1.33 m @ 3.02% WO3 & 0.67% Cu from 476.67 m

· 3.40 m @ 1.24 WO3 & 0.12% Cu from 493.00 m, including:

o 1.00 m @ 4.18% WO3 & 0.19% Cu from 495.40 m

· 10.20 m @ 0.72% Cu & 0.05% WO3 from 531.80m, including:

o 2.50m @ 1.09% Cu from 531.80 m, and

o 3.00 m @ 1.24% Cu from 539.00m

· 1.00 m @ 2.33% WO3 & 0.43% Cu from 562.00m

These results reinforce Redmoor's position as Europe's highest-grade undeveloped tungsten deposit*¹ (based on comparison with published JORC (2012) exploration results within Europe). Contributions to the results from copper also highlight the polymetallic nature of the deposit and indicate potential additional value from co-products. Tin assay results are being reviewed and are not included in this release.

Dennis Rowland, CRL Managing Director, said:

"These initial results demonstrate high tungsten grades and support Redmoor's position as one of the highest-grade deposits globally, when compared to other CRIRSCO (Committee for Mineral Reserves International Reporting Standards) resources.

"It is worth highlighting that these results are from only one borehole and yet demonstrate multiple, stacked zones of high-grade intersections within the Redmoor SVS deposit that correlate well with existing modelled high-grade zones and reinforce the strong grade continuity within the deposit. Results from CRD033 further identify new zones of potentially economic mineralisation within the Redmoor Deposit, which could contribute to the forthcoming mineral resource estimate update.

"We are now reviewing the geological log and analytical data from borehole CRD033. As a twin of a 1980s borehole drilled at Redmoor, this borehole has the potential to contribute towards the validation of the 1980s datasets and provide further project upside. Results of this review will be announced shortly."

Charles Manners, Strategic Minerals' Executive Chairman, said:

"The 2025 drilling programme is progressing very well and already providing impressive results, with these high-grade intersections further demonstrating Redmoor's globally significant status.

"It is in the Board's opinion that Redmoor's value has gone unrecognised, and our intention is to further progress the project and highlight its merits within a global context. With tungsten prices rising significantly this year, and a global push to secure access to critical and strategic minerals, Redmoor is well placed as a world leading asset.

"With two rigs now mobilised and progressing through the drilling programme, we eagerly await further results, as well as outputs from other ongoing workstreams as part of the match grant funded project. Redmoor is undertaking its most active period in recent history, with significant further news flow expected over coming weeks and months."

Overview of analytical results from CRD033

CRD033 was drilled south to intersect the Redmoor SVS mineralisation. Details of the collar and survey setup are provided in Table 1.

Table 1: Borehole collar data for CRD033

Collar | Orientation at Collar | Total Depth (m) | |||

Easting (m) | Northing (m) | Elevation (m) | Azimuth (⁰) | Dip (⁰) | |

235802 | 71342 | 186 | 161 | 65 | 600.5 |

The results from CRD033 confirm the continuity of numerous high-grade zones, as previously identified during the 2017-2018 diamond drilling programmes at Redmoor, along with the identification of additional mineralised structures outside of the current Mineral Resource estimate (MRE). Results from CRD033 illustrate the presence of 12 high-grade zones where minerals are concentrated within discrete structures within the wider, 90 m thick, Redmoor SVS.

The full extent of the 600.50 m hole was geologically logged and sampled (other than a small section where directional drilling was employed), resulting in the delineation of multiple quartz-greisen vein structures enriched in wolframite (WO3), chalcopyrite (Cu) and cassiterite (Sn), along with other accessory minerals. Notable intervals within the SVS include 3.05 m @ 1.43% WO3 from 439.70 m, (including 1.30 m @ 2.34% WO3 from 439.70 m to 441.00 m). A second high-grade zone over a 9.35 m interval has also been identified containing grades of 0.51% WO3 and 0.48% Cu, within this zone a structure has been sampled returning grades of 3.02% WO3 and 0.67% Cu over 1.33 m from 476.67 m. A further high-grade zone at 493.00 m containing 3.40 m @ 1.24% WO3, including 1.00 m @ 4.18% WO3 from 495.40 m. These results are consistent with Redmoor's high-grade character and will be incorporated into ongoing geological and resource evaluation work.

Reported widths are downhole. QAQC and analytical methods are summarised in detail in the Appendix (JORC Table 1, Sections 1-2). Sampling followed CRL's standard diamond-core protocols with half-core sampling, QAQC comprised routine insertion of certified reference materials (~7.5%), blanks (~5%), coarse and pulp duplicates (~5%), and umpire assays (~2.5%), around 20% control in total, plus XRF verification of W for samples ≥0.30%. All assays were performed by ALS Loughrea (ISO 17025). Snowden Optiro reviewed QA/QC; Tungsten (WO₃) and copper (Cu) results have passed QA/QC checks with no material issues identified and are reported following verification. Tin (Sn) assay results are being reviewed and are not included in this release.

Table 2: Highlights of downhole composite sample intervals returned from recently received results from borehole CRD033, showing interval lengths and subsequent assay results for WO3 & Cu. Composited values use a downhole length weighted average of grades.

CRD033 Sample Start | From (m) | To (m) | Interval (m) | WO3 % | Cu % | Comments |

CRL005141-48 | 365.15 | 372.65 | 7.50 | 0.04 | 0.27 | Lode-Style Cu Mineralisation |

incl. CRL005144 | 367.60 | 368.10 | 0.50 | 0.00 | 0.50 | Lode-Style Cu Mineralisation |

incl. CRL005145 | 370.30 | 371.60 | 1.30 | 0.05 | 0.50 | Lode-Style Cu Mineralisation |

CRL005199-5202 | 439.70 | 442.75 | 3.05 | 1.43 | 0.54 | S.V.S Mineralisation |

incl. CRL005199 | 439.70 | 441.00 | 1.30 | 2.34 | 0.44 | S.V.S Mineralisation |

incl. CRL005202 | 442.00 | 442.75 | 0.75 | 1.54 | 0.68 | S.V.S Mineralisation |

CRL005207-13 | 447.00 | 453.70 | 6.70 | 1.17 | 0.24 | S.V.S Mineralisation |

incl. CRL005212 | 451.20 | 453.20 | 2.00 | 3.86 | 0.54 | S.V.S Mineralisation |

CRL005227-36 | 468.65 | 478.00 | 9.35 | 0.51 | 0.48 | S.V.S Mineralisation |

incl. CRL005228 | 469.65 | 470.65 | 1.00 | 0.06 | 1.42 | S.V.S Mineralisation |

incl. CRL005234 | 474.45 | 475.20 | 0.75 | 0.52 | 0.21 | S.V.S Mineralisation |

incl. CRL005236 | 476.67 | 478.00 | 1.33 | 3.02 | 0.67 | S.V.S Mineralisation |

CRL005244 | 487.25 | 488.95 | 1.70 | 0.90 | 0.08 | S.V.S Mineralisation |

CRL005249-52 | 493.00 | 496.40 | 3.40 | 1.24 | 0.12 | S.V.S Mineralisation |

incl. CRL005252 | 495.40 | 496.40 | 1.00 | 4.18 | 0.19 | S.V.S Mineralisation |

CRL005264 | 509.70 | 510.70 | 1.00 | 0.32 | 0.52 | S.V.S Mineralisation |

CRL005271-76 | 518.50 | 524.50 | 6.00 | 0.03 | 0.29 | S.V.S Mineralisation |

incl. CRL005271 | 518.50 | 519.50 | 1.00 | 0.00 | 0.49 | S.V.S Mineralisation |

incl. CRL005273 | 520.45 | 521.50 | 1.05 | 0.14 | 0.47 | S.V.S Mineralisation |

incl. CRL005276 | 523.50 | 524.50 | 1.00 | 0.01 | 0.49 | S.V.S Mineralisation |

CRL005285-94 | 531.80 | 542.00 | 10.20 | 0.05 | 0.72 | S.V.S Mineralisation |

incl. CRL005285-86 | 531.80 | 534.30 | 2.50 | 0.05 | 1.09 | S.V.S Mineralisation |

incl. CRL005288 | 535.10 | 536.25 | 1.15 | 0.32 | 0.63 | S.V.S Mineralisation |

incl. CRL005292-94 | 539.00 | 542.00 | 3.00 | 0.01 | 1.24 | S.V.S Mineralisation |

CRL005298-99 | 548.00 | 550.00 | 2.00 | 0.01 | 0.54 | S.V.S Mineralisation |

CRL005304 | 556.00 | 557.00 | 1.00 | 0.08 | 0.63 | S.V.S Mineralisation |

CRL005309 | 562.00 | 563.00 | 1.00 | 2.33 | 0.43 | S.V.S Mineralisation |

CRL005335-37 | 589.75 | 594.00 | 4.25 | 0.05 | 0.18 | Skarn-Style Mineralisation |

incl. CRL005336 | 591.00 | 592.00 | 1.00 | 0.07 | 0.49 | Skarn-Style Mineralisation |

The high-grade tungsten intervals are accompanied by varying copper grades, consistent with Redmoor's polymetallic character. CRD033 results are considered by the Company to be high grade for tungsten and, on an indicative basis, compare favourably with published grades from undeveloped projects in Europe, supporting CRL's understanding that Redmoor is the highest grade, undeveloped tungsten deposit in Europe*¹, and amongst one of the highest grade globally.

*¹As far as CRL is aware following a review of active exploration projects with undeveloped assets in Europe, which have reported CRIRSCO-compliant resources, Redmoor has the highest tungsten grade.

Additional mineralised zones were also identified within CRD033 outside of the SVS and were logged as different mineralisation styles to those within the SVS (Table 2). Examples of these additional mineralised zones can be seen in samples CRL005141 to CRL005148, where mafic volcanic units contain "lode-style" copper mineralisation, with intersections reporting 1.30 m @ 0.50% Cu from 370.30 m, and 0.50 m @ 0.50% Cu from 367.60 m. At the base of CRD033, "skarn-style" mineralisation was identified with chalcopyrite and visible cassiterite logged by CRL geologists and verified using a handheld pXRF, with 4.25 m @ 0.18% Cu from 589.75 m, including 1.00m @ 0.49% Cu from 591.00 m. These mineralised bodies lie outside the SVS deposit and current Redmoor JORC (2012) MRE and will be the subject of further evaluation to determine significance and prospectivity, alongside the addition of pending tin results.

A review of CRD033, drilled as a twin to the 1982 SWM hole RM82-22, is underway to assess data comparability and support validation of the historical dataset and use in the forthcoming Mineral Resource estimate update and future drill programmes. This will be supported by results from further twin boreholes following receipt of laboratory results.

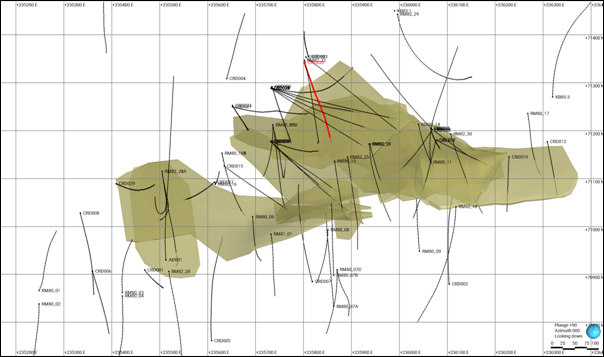

Figure 1 shows a plan view of all drilling carried out to date at Redmoor (in black), and the trace of CRD033 (in red). The current SVS model of high-grade zones is shown in gold dipping steeply to the north.

Figure 1: Plan view of existing Redmoor boreholes (in black), including CRL (CRD) and SWM (RM) boreholes, and the trace of CRD033 (in red), highlighting its path as a twin borehole. The current SVS model of high-grade zones is shown in gold dipping steeply to the north.

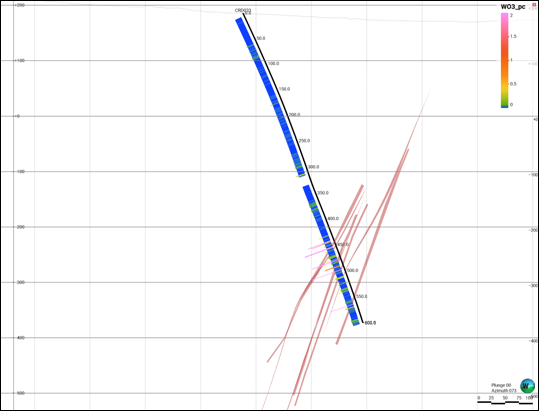

Figure 2 shows a cross-section view from north (left) to south (right) of CRD033 only. The trace is coloured by WO3, showing the sample results from top to bottom of the borehole, and includes an analytical gap where directional drilling was used meaning no core was recovered. Figure 2 also displays the currently interpreted high-grade zones within the SVS (modelled prior to CRD033) which are coloured in red for reference. Higher grade sample results are shown to correlate well with the modelled high-grade zones produced prior to these results, aiding in the validation of the new model.

Figure 2: Cross=section of CRD033 showing WO₃ analytical results, and wireframes for SVS high grade zones

Competent Person Statement:

The information in this announcement that relates to Sampling Techniques and Data and Exploration Results has been reviewed and approved by Mr Laurie Hassall, MSci (Geology), FIMMM, QMR, FGS, who is a full-time employee of Snowden Optiro. Mr Hassall holds a Master of Science degree in Geology from the University of Southampton and is a Fellow of the Institute of Materials, Minerals and Mining (FIMMM), through which he is also accredited as Qualified for Minerals Reporting (QMR). He is also a Fellow of the Geological Society of London (FGS).

Snowden Optiro has been engaged by Cornwall Resources Limited to provide independent technical advice. Mr Hassall, a full-time employee of Snowden Optiro, is acting as the Competent Person and is independent of Cornwall Resources Limited. He has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration, and to the activity being undertaken, to qualify as a Competent Person as defined in the 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (JORC Code), and under the AIM Rules.

Mr Hassall consents to the inclusion in this announcement of the matters based on his information, in the form and context in which it appears. He confirms that, to the best of his knowledge, there is no new information or data that materially affects the information contained in previous market announcements, and that the form and context in which the information is presented has not been materially modified.

For further information, please contact: |

| |

Strategic Minerals plc | +44 (0) 207 389 7067 | |

Mark Burnett | ||

Executive Director | ||

Website: | www.strategicminerals.net | |

Email: | ||

| ||

Follow Strategic Minerals on: | ||

X: | @StrategicMnrls | |

LinkedIn: | https://www.linkedin.com/company/strategic-minerals-plc | |

SP Angel Corporate Finance LLP |

+44 (0) 20 3470 0470 | |

Nominated Adviser and Broker | ||

Matthew Johnson/Charlie Bouverat/Grant Barker

Zeus Capital Limited Joint Broker Harry Ansell/Katy Mitchell | +44 (0) 203 829 5000 | |

|

| |

Vigo Consulting | +44 (0) 207 390 0234 | |

Investor Relations | ||

Ben Simons/Peter Jacob/Anna Sutton | ||

Email: | ||

Notes to Editors

About Strategic Minerals plc and Cornwall Resources Limited

Strategic Minerals plc (AIM: SML; USOTC: SMCDY) is an AIM-quoted, producing minerals company, actively developing strategic projects in the UK, United States and Australia.

In 2019, the Company completed the 100% acquisition of Cornwall Resources Limited and the Redmoor Tungsten-Tin-Copper Project.

The Redmoor Project is situated within the historically significant Tamar Valley Mining District in Cornwall, United Kingdom, with a JORC (2012) Compliant Inferred Mineral Resource Estimate published 14 February 2019:

Cut-off (SnEq%) | Tonnage (Mt) | WO3 % | Sn % | Cu % | Sn Eq1 % | WO3 Eq % |

>0.45 <0.65 | 1.50 | 0.18 | 0.21 | 0.30 | 0.58 | 0.41 |

>0.65 | 10.20 | 0.62 | 0.16 | 0.53 | 1.26 | 0.88 |

Total Inferred Resource | 11.70 | 0.56 | 0.16 | 0.50 | 1.17 | 0.82 |

1 Equivalent metal calculation notes; Sn(Eq)% = Sn% x 1 + WO3% x 1.43 + Cu% x 0.40. WO3(EQ)% = Sn% x 0.7 + WO3 + Cu% x 0.28. Commodity price assumptions: WO₃ US$ 33,000/t, Sn US$ 22,000/t, Cu US$ 7,000/t. Recovery assumptions: total WO3 recovery 72%, total Sn recovery 68% & total Cu recovery 85% and payability assumptions of 81%, 90% and 90% respectively

More information on Cornwall Resources can be found at: https://www.cornwallresources.com

In September 2011, Strategic Minerals acquired the distribution rights to the Cobre magnetite project in New Mexico, USA, through its wholly owned subsidiary Southern Minerals Group. Cobre has been in production since 2012 and continues to provide a sustainable revenue stream for the Company.

In March 2018, the Company completed the acquisition of the Leigh Creek Copper Mine situated in the copper rich belt of South Australia. The Company has entered into an exclusive Call Option with South Pacific Mineral Investments Pty Ltd trading as Cuprum Metals to acquire 100% of the project.

About the CIOS Good Growth Fund and UK Shared Prosperity Fund

This project is part-funded by the UK Government through the UK Shared Prosperity Fund. Cornwall Council is responsible for managing projects funded by the UK Shared Prosperity Fund through the Cornwall and the Isles of Scilly Good Growth Programme.

Cornwall and Isles of Scilly has been allocated £184 million for local investment through the Shared Prosperity Fund. This new approach to investment is designed to empower local leaders and communities, so they can make a real difference on the ground where it's needed the most.

The UK Shared Prosperity Fund proactively supports delivery of the UK-government's five national missions: pushing power out to communities everywhere, with a specific focus to help kickstart economic growth and promoting opportunities in all parts of the UK.

For more information, visit

https://www.gov.uk/government/publications/uk-shared-prosperity-fund-prospectus

For more information, visit https://ciosgoodgrowth.com

Appendix 1: Individual Sample Results Table for Composites

Individual Laboratory Results Per Sample used to form highlighted composite intervals(Sample ranges and numbers in bold represent those listed in Table 2, above. Results include sample number, intersected depths and interval length, and WO₃ and Cu values. WO₃ is calculated from W results by applying a factor of 1.26 to the result)

Sample Start | From (m) | To (m) | Interval (m) | WO3 % | Cu % |

CRL005141-48 | |||||

CRL005141 | 365.15 | 365.88 | 0.73 | 0.06 | 0.36 |

CRL005142 | 365.88 | 366.65 | 0.77 | 0.03 | 0.29 |

CRL005143 | 366.65 | 367.60 | 0.95 | 0.04 | 0.05 |

CRL005144 | 367.60 | 368.10 | 0.50 | 0.00 | 0.50 |

CRL005145 | 368.10 | 369.55 | 1.45 | 0.08 | 0.21 |

CRL005146 | 369.55 | 370.30 | 0.75 | 0.02 | 0.10 |

CRL005147 | 370.30 | 371.60 | 1.3 | 0.05 | 0.50 |

CRL005148 | 371.60 | 372.65 | 1.05 | 0.01 | 0.23 |

CRL005199-5202 | |||||

CRL005199 | 439.70 | 441.00 | 1.30 | 2.34 | 0.44 |

CRL005201 | 441.00 | 442.00 | 1.00 | 0.16 | 0.57 |

CRL005202 | 442.00 | 442.75 | 0.75 | 1.54 | 0.68 |

CRL005207-13 | |||||

CRL005207 | 447.00 | 448.00

| 1.00 | 0.12 | 0.38 |

CRL005208 | 448.00 | 449.70 | 1.70 | 0.00 | 0.01 |

CRL005209 | 449.70 | 450.20 | 0.5 | 0.01 | 0.08 |

CRL005211 | 450.20 | 451.20 | 1.00 | 0.00 | 0.02 |

CRL005212 | 451.20 | 453.20 | 2.00 | 3.86 | 0.54 |

CRL005213 | 453.20 | 453.7 | 0.50 | 0.03 | 0.15 |

CRL005227-36 | |||||

CRL005227 | 468.65 | 469.65 | 1.00 | 0.14 | 0.27 |

CRL005228 | 469.65 | 470.65 | 1.00 | 0.06 | 1.42 |

CRL005229 | 470.65 | 471.40 | 0.75 | 0.17 | 0.94 |

CRL005231 | 471.40 | 472.15 | 0.75 | 0.00 | 0.02 |

CRL005232 | 472.15 | 473.65 | 1.5 | 0.00 | 0.02 |

CRL005233 | 473.65 | 474.45 | 0.8 | 0.00 | 0.33 |

CRL005234 | 474.45 | 475.20 | 0.75 | 0.52 | 0.21 |

CRL005235 | 475.2 | 476.67 | 1.47 | 0.01 | 0.52 |

CRL005236 | 476.67 | 478.00 | 1.33 | 3.02 | 0.67 |

CRL005244 | 487.25 | 488.95 | 1.70 | 0.90 | 0.08 |

CRL005249-52 | |||||

CRL005249 | 493.00 | 494.00 | 1.00 | 0.01 | 0.21 |

CRL005251 | 494.00 | 495.40 | 1.4 | 0.00 | 0.00 |

CRL005252 | 495.40 | 496.40 | 1.00 | 4.18 | 0.19 |

CRL005264 | 509.70 | 510.70 | 1.00 | 0.32 | 0.52 |

CRL005271-76 | |||||

CRL005271 | 518.50 | 519.50 | 1.00 | 0.00 | 0.49 |

CRL005272 | 519.50 | 520.45 | 0.95 | 0.01 | 0.11 |

CRL005273 | 520.45 | 521.50 | 1.05 | 0.14 | 0.47 |

CRL005274 | 521.50 | 522.60 | 1.10 | 0.00 | 0.03 |

CRL005275

| 522.60

| 523.50

| 0.90

| 0.00

| 0.19

|

CRL005276 | 523.50 | 524.50 | 1.00 | 0.01 | 0.49 |

CRL005285-94 | |||||

CRL005285 | 531.80 | 533.80 | 2.00 | 0.06 | 1.07 |

CRL005286 | 533.80 | 534.30 | 0.50 | 0.02 | 1.155 |

CRL005285-86 | |||||

CRL005287 | 534.30 | 535.10 | 0.80 | 0.00 | 0.04 |

CRL005288 | 535.10 | 536.25 | 1.15 | 0.32 | 0.63 |

CRL005289 | 536.25 | 537.00 | 0.75 | 0.00 | 0.02 |

CRL005291 | 537.00 | 539.00 | 2.00 | 0.01 | 0.08 |

CRL005292-94 | |||||

CRL005292 | 539.00 | 540.00 | 1.00 | 0.00 | 0.90 |

CRL005293 | 540.00 | 541.00 | 1.00 | 0.01 | 0.01 |

CRL005294 | 541.00 | 542.00 | 1.00 | 0.00 | 2.80 |

CRL005298-99 | |||||

CRL005298 | 548.00 | 549.00 | 1.00 | 0.00 | 0.31 |

CRL005299 | 549.00 | 550.00 | 1.00 | 0.01 | 0.77 |

CRL005304 | 556.00 | 557.00 | 1.00 | 0.08 | 0.63 |

CRL005309 | 562.00 | 563.00 | 1.00 | 2.33 | 0.43 |

CRL005335-37 | |||||

CRL005335 | 589.75 | 591.00 | 1.25 | 0.06 | 0.14 |

CRL005336 | 591.00 | 592.00 | 1.00 | 0.07 | 0.49 |

CRL005337 | 592.00 | 594.00 | 2.00 | 0.04 | 0.05 |

Appendix 2: JORC Code, 2012 Edition -Table 1

Redmoor Tungsten-Tin-Copper Project

Section 1 Sampling Techniques and Data(Criteria in this section apply to all succeeding sections)

Criteria | JORC Code explanation | Commentary |

Sampling techniques | · Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. · Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. · Aspects of the determination of mineralisation that are Material to the Public Report. · In cases where 'industry standard' work has been done this would be relatively simple (eg 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information. | CRL 2025 drilling · Diamond drill core was aligned prior to splitting and halved using a core saw, based on geological boundaries and differing mineralised structures, typically of 1 m sample length, and up to 2 m in less mineralised zones. Sections that did not appear mineralised were not sampled, however CRD033 was sampled in its entirety to collect a full geochemical profile of the orebody. · Drilling was aligned as close as possible to perpendicular to the SVS.

CRL 2017-2018 drilling · Core was aligned prior to splitting and halved using a core saw, based on geological boundaries, typically of 1 m sample length, and up to 2.5 m in less mineralised zones. Sections that did not appear mineralised were not sampled. · Drilling was orientated where possible to intersect the target as closely as possible to perpendicular. The deposit contains multiple different mineralisation sets, and so for this reason and limitations of access, not all holes comply with this. SWM 1980-1983 drilling · In addition to CRL drilling, South West Minerals (SWM) completed a diamond-core surface programme in 1980-1983. These data are used alongside CRL drilling within the Redmoor database. Historical SWM assays were retrospectively verified at the time by Robertson Research International with independent check assays at Alfred H. Knight, and later by SRK/NAE core resampling; Snowden Optiro's 2025 review and twin-hole work provide additional verification for use in current reporting · The drilling was orientated to intersect the mineralisation at high angles with the exception, in many cases, of Johnson's Lode as this dips in the opposite direction to the other lodes and SVS. The holes were sampled for assaying and density measurements. |

Drilling techniques | · Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). | CRL drilling · For the 2025 campaign, all drilling was carried out by diamond core drilling, of HQ to NQ diameter (63.5-47.6mm). · Core was oriented through all of the core drilled where possible, using a Reflex ACTx system. · For the 2018 campaign, all drilling was carried out by diamond core drilling, of HQ to NQ diameter (63.5-47.6mm). · Core was oriented through the majority of the core drilled, using a Reflex ACT III system. · For the 2017 campaign, all drilling was carried out by diamond core drilling, of HQ3 to BTW diameter (61-42mm). · Core was generally oriented within the mineralised zone, using a Reflex ACT II system. SWM drilling · All historic drillholes were completed using HQ, NQ or BQ diamond core. · The holes were primarily orientated to intersect the northerly dipping vein system from the north, however a small number were orientated to intercept southerly dipping lodes. |

Drill sample recovery | · Method of recording and assessing core and chip sample recoveries and results assessed. · Measures taken to maximise sample recovery and ensure representative nature of the samples. · Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. | CRL 2025 drilling · Recovery was generally good through mineralisation and entirety of the drill holes, and typically better than 95%. All core was joined, measured by run length, and correlated to core blocks, and recoveries were measured for each run drilled within 24 hours of being drilled. · Core recoveries were checked against drilling records to ensure consistency. · Broken ground where structures were encountered and any core loss recorded clearly logged as such. · Other than where broken ground is encountered, no negative relationship was seen between recovery and mineralisation. CRL 2018 drilling · Recoveries were generally good through mineralisation, and typically better than 90%. Recoveries were measured for each run drilled, normally within 24 hours of the hole being drilled. · Voids where encountered were clearly logged as such. · Other than where an area may have been mined, as mentioned above, no negative relationship was seen between recovery and mineralization and this has been reviewed by Snowden Optiro. CRL 2017 drilling · Recoveries were generally good through mineralisation, and typically better than 90%. Recoveries were measured for each run drilled, normally within 24 hours of the hole being drilled. · Triple Tube drilling was used where possible given available equipment and core diameter, to enable precise definition of recovery. · Voids where encountered were clearly logged as such. · Other than where an area may have been mined, as mentioned above, no negative relationship was seen between recovery and grade. SWM drilling · All historic drillholes were completed using HQ, NQ or BQ diamond core. Core recovery was recorded on the logs and the results suggest that the core recovery was relatively high, typically ranging from 80% to 100%, the higher losses being in areas of poor ground. Snowden Optiro is not aware of specific measures taken to reduce core loss but where excessive losses were experienced holes were typically and often re-drilled. There is no apparent relationship between core loss and grade. |

Logging | · Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. · Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. · The total length and percentage of the relevant intersections logged. | CRL drilling · All drill core was digitally logged producing detailed structural logs recording Alpha and Beta angles using a Kenometer, recording each individual vein and structural zone, alteration zones and geotechnical characteristics. · Select samples were taken for petrographic studies in order to support observations and clarify mineralogical observations. · All core was photographed and referenced to downhole geology using Leapfrog software. · Voids and broken ground, where encountered, were clearly logged as such. · Logging template improvements were made for the 2025 drilling, that included capturing separate lithology, structural, alteration and mineralisation tables SWM drilling · Detailed geological core logging and recording of the features of the core was undertaken as part of the historic drilling campaign and these logs remain available for review. · Mineralogical descriptions are qualitative but detailed. Details of all relevant intersections are separately noted. |

Sub-sampling techniques and sample preparation | · If core, whether cut or sawn and whether quarter, half or all core taken. · If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. · For all sample types, the nature, quality and appropriateness of the sample preparation technique. · Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. · Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling. · Whether sample sizes are appropriate to the grain size of the material being sampled. | CRL 2025 drilling · Sawn half core was used for all samples submitted to the laboratory. The remaining half-core is preserved in the core trays as a record. · The routine sample procedure is always to take the half core to the left of the orientation line looking down the hole. · The halved samples were submitted to ALS Loughrea laboratory. · All samples, typically in the range 2-7 kg were dried and finely crushed to better than 95 % passing a 2 mm screen. A split of 1000 g was taken and pulverised to better than 85 % passing a 75 micron screen. · Once assay results are received, the results from certified reference material, and blank samples are compared with expected certified concentrations and the corresponding duplicate samples are compared to ascertain whether the sampling is representative. · Copies of internal laboratory QC validating that the targeted particle size was being achieved were received and reviewed. · Sample sizes are considered appropriate for the style and type of mineralisation, if halved core is used. CRL 2017-2018 drilling · Sawn half core was used for all samples submitted to the laboratory. The remaining half-core is preserved in the core trays as a record. · The routine sample procedure was always to take the half core to the left of the orientation line looking down the hole. · The halved samples were submitted to ALS Loughrea laboratory. · For holes CRD001 to CRD013, samples, typically in the range 3-7 kg were dried and finely crushed to better than 70 % passing a 2 mm screen. A split of up to 250 g was taken and pulverized to better than 85 % passing a 75 micron screen. · For holes CRD014 onwards, samples, typically in the range 3-7 kg were dried and finely crushed to better than 95 % passing a 2 mm screen. A split of 1000 g was taken and pulverized to better than 85 % passing a 75 micron screen. · Copies of internal laboratory QC validating that the targeted particle size was being achieved were received. · % of samples were re-assayed as coarse reject duplicates. · Once assay results were received, the results from duplicate samples were compared with the corresponding routine sample to ascertain whether the sample preparation steps were not introducing bias or imprecision. · Sample sizes are considered appropriate for the style and type of mineralisation, if halved core is used. · CRL 2025 new samples. SWM drilling · Historic SWM core was generally sampled at ~2 m intervals using two methods: split half-core and geochemical chip sampling. Chip samples (material washed from the core barrel) are considered non-representative and are not used for estimation; only split-core samples are retained for verification and modelling work. Sample-type codes in the database distinguish SC (split core), G (chip), and SCG (split core for Sn/W with chip for other analytes). Contemporary QAQC (standards/blanks/duplicates) was not implemented in 1980-83; however, Robertson Research International undertook retrospective checks with Alfred H. Knight (c.10% of samples) and re-assayed Redmoor submissions following identification and correction of an analytical issue, providing reasonable confidence in the WO₃ data. SRK/NAE later performed limited core resampling. |

Quality of assay data and laboratory tests | · The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. · For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. · Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established. | CRL 2025 drilling · Analysis by method ME-MS61 was carried out using a HF-HNO3-HClO4 acid digestion, HCl leach, and analysed with a combination of ICP-MS and ICP-AES, including Sn, Cu, and W. The upper and lower detection limits have previously been tested and predetermined by CRL and confirmed acceptable for the target elements of Sn, Cu, and W. A limited number of samples were also analysed for Cu, Pb and Zn by method OG62. · Where grades by method ME-MS61 exceed 0.30% W, as previously determined by internal review, an additional assay for high grade W by method ME-XRF15b was subsequently carried out. These results replace relevant W values for ME-MS61. Where grades by method ME-MS61 exceed 500 ppm Sn, an additional assay for high grade Sn was carried out using ME-XRF15b. · The laboratory shared their internal QC data on blanks, pulp duplicates and CRMs. CRL also inserted 7.5% CRMs to test WO₃, Sn and Cu analyses and 5% blanks along with 5% coarse and pulp duplicates, as a further control. · CRM standards were reproducible and within analytical ranges as certified; CRL's blanks show no significant contamination issues and the assays of the laboratory standards, which cover a range of metal values for each of Sn, Cu, WO₃, show no material bias. · 2.5 % of samples are selected for umpire assays at an independent laboratory and project-specific CRMs for WO₃ and Sn to maintain long-term analytical confidence. CRL 2017-2018 drilling · Analysis by method ME-ICP81x was carried out using a sodium peroxide fusion for decomposition and then analysed by ICP-AES for 34 elements, including Sn, Cu, and W. The upper and lower detection limits are considered acceptable for the target elements of Sn, Cu, and W. A limited number of samples were also analysed for silver by method Ag-ICP61. · Assay method selection (2017-2018): Where WO₃ by ME-ICP81x exceeded 0.50% WO₃, samples were re-analysed by XRF (ME-XRF15b) and the XRF results replaced the corresponding ICP values for reporting and resource evaluation. · Pulp re-assay and updated trigger (2024/2025): Following a review, the XRF trigger was lowered to 0.30% WO₃. CRL re-assayed 73 pulps by XRF at ALS; results showed an ~9% average increase in WO₃ relative to the original ICP assays (with the majority returning higher grades). This work confirms XRF as the preferred method for samples ≥0.30% WO₃ and supports its use for future estimation and reporting. · The laboratory shared their internal QC data on blanks, pulp duplicates and standards. CRL also inserted 5% each of blanks, standards and coarse duplicates, as a further control. · While there was some spread in the repeatability of the 2017 coarse rejects the results are acceptable and to industry guidelines; CRL's blanks show no significant contamination issues and the assays of the laboratory standards, which cover a range of metal values for each of Sn, Cu, W, show no bias subject to the protocol above being used. SWM drilling · Historic SWM drill core was predominantly sampled at ~2 m intervals using two methods: split half-core and geochemical chip sampling. Chip samples are interpreted to comprise material washed from the core barrel and are concentrated in low-grade or unmineralised zones; due to representativity limitations they are not recommended for use in grade estimation. For verification and estimation, Snowden Optiro advises using split-core samples only. · Historical SWM assay data were generated by RRI using XRF and colorimetric methods; subsequent check work by Alfred H. Knight provide a basis for confidence in the original WO₃ results. · No additional information is available on the quality control programmes used for the historic drilling. · SRK/NAE re-sampled selected SWM core in 2012-2013 for verification. Snowden Optiro reviewed these results and concluded that the quarter-core versus quarter-core methodology was sub-optimal for the coarse, nuggety wolframite mineralisation at Redmoor. Future verification was recommended to employ half-core versus half-core resampling to maintain equivalent sample support, or through twin hole verification. |

Verification of sampling and assaying | · The verification of significant intersections by either independent or alternative company personnel. · The use of twinned holes. · Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. · Discuss any adjustment to assay data. | CRL 2025 drilling · Internal review of all assay and QA/QC data was undertaken internally by CRL geologists and Exploration Manager, with review undertaken externally by Snowden Optiro. · CRL previously undertook analytical checks and reviews on historical pulp samples, confirming the necessity for lower trigger limits for W analysis (from 0.5% to 0.3%), with ME-XRF 15b analyses showing an increase in W grade in a majority of samples, these results were incorporated into the revised assay database. Checks for Sn trigger limits were tested, which were kept at 500 ppm. CRL 2018 drilling · Geologica UK previously validated the 2018 drilling database against laboratory certificates. In 2025, Snowden Optiro completed an additional independent check of the 2017-2018 assay data against original lab files. CRL in 2024/2025 also undertook targeted pulp re-assays (XRF) to confirm WO₃ grades · Snowden Optiro consider the dataset fit for Mineral Resource estimation. CRL 2017 drilling · SRK previously reviewed the database and laboratory certificates and confirmed significant intersections. In 2025, Snowden Optiro re-reviewed these data as part of a comprehensive assessment of previous datasets, confirming the earlier conclusions and data integrity. · Snowden Optiro received copies of CRL's database and laboratory analysis certificates and reviewed the significant intersections. · SRK conducted a site visit and audit in 2017. Snowden Optiro completed multiple site visits (2025) and reviewed data entry, chain-of-custody and verification procedures. CRL maintains routine off-site backups; Snowden Optiro also recommended (and CRL is implementing) migration to a secure relational database and standardisation of historic SWM and CRL datasets. · Within significant intercepts, values at detection limits were replaced with 0.5 of the detection limit value. Where duplicate assays exist the primary sample assay is used. · CRL's 2017-2018 diamond drilling data and QAQC results have been independently reviewed by Snowden Optiro; no material issues were identified, and the dataset is considered fit for use in resource estimation. SWM drilling · Historical SWM drilling (1980-1983) was completed prior to the routine implementation of QAQC procedures; however, records show that the primary laboratory, Robertson Research International (RRI), conducted internal check analyses. RRI submitted approximately 10 % of samples for independent check assays at Alfred H. Knight Laboratories. All Redmoor samples since April 1980 were re-assayed due to an issue with a faulty x-ray tube. Snowden Optiro considers this an appropriate historical verification step providing reasonable confidence in the WO₃ data. · SRK re-sampled selected SWM core in 2012-2013 for verification. Snowden Optiro reviewed these results and concluded that the quarter-core versus quarter-core methodology was sub-optimal for the coarse, nuggety wolframite mineralisation at Redmoor. Snowden Optiro recommended twin drilling as a better and more appropriate technique for verification. · Snowden Optiro and CRL jointly planned a programme of twin-hole drilling, designed to verify the SWM dataset through direct comparison of lithology, structure, and assay tenor. The first of these, CRD033 (twin of RM82-22) as reported in this RNS, provides an encouraging result, confirming the same mineralised zones and no systematic grade bias. · Snowden Optiro has undertaken side-by-side sectional reviews and statistical checks (including Q-Q plots, depth-aligned paired analyses, and grade-threshold comparisons) as part of its independent verification process. · Collar locations for selected SWM holes (e.g., RM80-05 and RM80-05B) were verified in the field by Snowden Optiro using handheld GPS; down-hole survey data and the -8° magnetic-to-grid correction were checked and confirmed as appropriate. · Through recent re-modelling work, Snowden Optiro has independently checked relevant original logs against those captured in the current database and conformable with the level of data captured in the SRK digitisation and that no material transcription errors have taken place. |

Location of data points | · Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. · Specification of the grid system used. · Quality and adequacy of topographic control. | CRL 2025 drilling · Planned collar locations were recorded as six-figure grid references, together with RL values in meters, in the British National Grid (OSGB) coordinate system. · Final collar coordinates were recorded using a Reach RS2 GPS receiver, with variation from planned position within 10 m. · Downhole surveys were conducted using the Reflex EZ-Trac system, as a minimum every 30m downhole. A multi-shot survey, using the Reflex EZ-Trac system, is collected when drill diameter is reduced from HQ to NQ diameter and at the end of hole, with survey readings taken every 3m up hole. Aluminium extension rods were used to minimise magnetic error. · Data were synchronised with the online IMDEX HUB-IQ online data management system, with survey data reviewed by CRL geologists and QA/QC parameters checked to validate survey data. · Initial collar set up was conducted using an optical sighting compass, at least 10m from the rig, for azimuth, and an inclinometer on the rig for inclination; azimuth was checked prior to drill rig set up and following set up of drill pad and levelling of dril rig. CRL 2018 drilling · Planned collar locations were recorded as six-figure grid references, together with RL values in meters, in the British National Grid (OSGB) coordinate system. These were surveyed using a real-time corrected DGPS operated by a professional survey company, 4D Civil Engineering Surveying Ltd (4D-CES). Final pick -up of actual hole positions is completed on completion of each site; variation from planned positions is generally <5 m. · Downhole surveys were conducted using the Reflex EZ-Trac system, as a minimum every 50m downhole. Aluminium extension rods were used to minimise magnetic error. · Initial collar set up was conducted using an optical sighting compass, at least 10m from the rig, for azimuth, and an inclinometer on the rig for inclination. CRL 2017 drilling · Collar locations were recorded as six-figure grid references, together with RL values in metres, in the British National Grid (OSGB) coordinate system. These were surveyed using a real-time corrected DGPS operated by a professional survey company. · Downhole surveys were conducted using the Reflex EZ-Trac system, as a minimum every 50m downhole. Aluminium extension rods were used to minimise magnetic error. · Initial collar set up was conducted using an optical sighting compass, at least 10m from the rig, for azimuth, and an inclinometer on the rig for inclination. SWM drilling · Historic drillhole logs present collar locations as six-figure grid references in British National Grid (OSGB) coordinate system. In the absence of RL data, SRK has projected collars on to (2005) Lidar topographic survey data. · Downhole surveys were typically recorded using either acid tube test or single shot survey camera, with readings taken at approximately every 50 m. · Historic plans of the drilling and drillhole traces have been digitised and Snowden Optiro have reviewed database collars vs georeferenced plans and is satisfied with the coordinate positions. |

Data spacing and distribution | · Data spacing for reporting of Exploration Results. · Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. · Whether sample compositing has been applied. | CRL 2025 drilling · The programme aimed to extend previously identified mineralisation, confirm validity of SWM drilling and its use in a Mineral Resource estimate, and identify mineralisation within the exploration target area as defined in the 2020 Scoping Study . · Twinned drill hole spacing is typically 10-25 m apart, and reasonably follow the same azimuth and dip. · Data spacing provides an acceptable degree of geological and grade continuity for Mineral Resource estimation in the Inferred category. · Samples were composited to 2 m for continuity analysis and estimation. CRL 2018 drilling · The programme aimed to extend previously identified mineralisation. · Data spacing is typically 70/80-150m apart, and locally less. · Data spacing provides an acceptable degree of geological and grade continuity for Mineral Resource estimation in the Inferred category. · Samples were composited to 2m for continuity analysis and estimation. CRL 2017 drilling · The programme aimed at extending and improving continuity of previously identified mineralisation. · The data spacing varies depending on the target, within the SVS this is 100-150m apart, and often less. · Compositing was applied in order to calculate intersected width equivalents, on an interval length weighted-average basis. SWM drilling · The drillholes and sample intersections are typically some 100-150m apart in the main lodes and lode systems of interest which has provided a reasonable indication of continuity of structure for the SVS, Johnson's Lode and the Great South Lode. All individual sample assays remain available. |

Orientation of data in relation to geological structure | · Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. · If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. | CRL 2025 drilling · Drillholes in the programme target the SVS and as secondary target ancillary lodes, such as Johnsons lode. · All drillholes were drilled perpendicular to the SVS with the objective of collecting drill core that best represents mineralised zones and give the best representation of the geology, mineralisation and geometry of the orebody. · Drilling has confirmed the continuity of previously drilled High-Grade zones and the continuity of geological structures containing mineralisation. Furthermore, twinned drill holes have confirmed the continuity of WO₃, Sn and Cu grade along logged geological structures. CRL 2018 drilling · Drillholes in the programme target the SVS and as secondary targets ancillary lodes such as Kelly Bray lode. · In order to minimize impact on local residents, some holes were drilled oblique to the mineralisation. · Notwithstanding this, the SVS mineralisation is interpreted to be a broad tabular mineralised zone. The orientation of the drilling is believed to be appropriate for the evaluation of this geometry as presently understood. CRL 2017 drilling · Drillholes in the programme targeted the SVS, Johnson's Lode, Great South Lode, and Kelly Bray Lode, each of which has different dips. · Some holes hit more than one of the above, and therefore could not be perpendicular to all mineralisation. · In order to minimize impact on local residents, some holes were drilled oblique to the mineralisation. · Notwithstanding this, the SVS mineralisation is interpreted to be a broad tabular mineralised zone with an internal plunge component. The orientation of the drilling is believed to be appropriate for the evaluation of this geometry as presently understood. It is recommended that this be further assessed during subsequent drilling. · Intercepts are reported as apparent thicknesses except where otherwise stated. The data spacing varies depending on the target, within the SVS this is 100-150m apart, and often less. SWM drilling · The drillholes and sample intersections are typically some 100-150m apart in the main lodes and lode systems of interest which has provided a reasonable indication of continuity of structure for the SVS, Johnson's Lode and the Great South Lode. All individual sample assays, and some of the drill core, remain available. · The drillholes were orientated to intersect the SVS and Great South Lode at intersection angles of between 45 and 90 degrees. Two or three holes were though often drilled from one site to limit the number of drill sites needed and also the intersection angles with Johnson's Lode are shallower then ideal due to the different orientation of this structure. Full intersections are however available in all cases so there should be no material bias and the differences between intersected and true lode widths has been accounted for in SRK's evaluation procedures. |

Sample security | · The measures taken to ensure sample security. | CRL drilling · All drill core is stored at CRL's warehouse/office in Kelly Bray Callington, with no possible access from the public. All core is securely stored on racking and recorded, with historical pulp and coarse reject samples stored at CRL's office for any future review. SWM Drilling · All remaining SWM drill core is in CRL's custody and is stored on private land, for which CRL has continued access. |

Audits or reviews | · The results of any audits or reviews of sampling techniques and data. | CRL drilling · Snowden Optiro audited CRL's sampling, logging, and QAQC procedures during a comprehensive review in 2025 and found them to meet industry best practice. · Snowden Optiro undertook six site visits to CRL's Redmoor Project to review and audit drilling, logging, density measurement and sampling practices, as well as standard operating procedures and is satisfied that CRL are performing all to a high standard. · SRK previously audited CRL's 2017 drilling programme (June 2017) and identified no significant issues. SWM drilling · No external audit of the historical SWM QAQC is known other than those undertaken by SRK and Snowden Optiro. |

Section 2 Reporting of Exploration Results

(Criteria in this section apply to all succeeding sections)

Criteria | JORC Code explanation | Commentary | ||||||||||||||||||||

Mineral tenement and land tenure status | · Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. · The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. | · The Project is located immediately south of the village of Kelly Bray and approximately 0.5km north of the town of Callington in Cornwall in the United Kingdom. · In October 2012, NAE Resources (UK) Limited acquired a 100% interest in the Redmoor Tin-Tungsten Project through an Exploration License and Option Agreement with the owner of mineral rights covering a large area of approximately 23km² that includes the Redmoor Project. The Exploration License was granted for an initial period of 15 years with modest annual payments. On 14 November 2016, NAE Resources (UK) Limited changed its name to Cornwall Resources Limited (CRL). · On 26 May 2016 Strategic Minerals Plc (SML) entered into an option agreement with NAE to buy a 50% interest in CRL. In March 2019, the Company entered into arrangements to acquire the balance of CRL, and this was completed on 24 July 2019. · On 21 April 2022, SML announced a 10-year extension of CRL's Redmoor Exploration Licence until October 2037. · CRL also has the option to a 25-year Mining Lease, extendable by a further 25 years which can be exercised at any time during the term of the Exploration License. The Mining Lease permits commercial extraction of the minerals subject to obtaining planning and other approvals required and is subject to a 3% Net Smelter Return royalty payable to the mineral right owner once commercial production has commenced. CRL also has a pre-emptive right over the sale of the mineral rights by the vendor. Surface land access for exploration drilling and mining over some of the Redmoor deposit is also included in these agreements. · In addition to the Redmoor exploration licence, CRL holds further licence agreements with two other mineral rights owners, including the Duchy of Cornwall, for a total mineral rights area within the historic Tamar Valley Mining District of 91.67km2. | ||||||||||||||||||||

Exploration done by other parties | · Acknowledgment and appraisal of exploration by other parties. | · Historical exploration was completed by South West Minerals (SWM) between 1980 and 1983, consisting of diamond drilling and limited underground channel sampling of Redmoor adit. Data from this programme form part of the current geological and assay database. Verification of these data has included laboratory check assays by Alfred H. Knight (1980), SRK/NAE core resampling (2012-2013), and ongoing twin-hole validation by CRL under Snowden Optiro supervision (2025). · The Redmoor area was the subject of underground development and processing from the 18th century to around 1946. · Snowden Optiro is unaware of any exploration undertaken by parties other than South West Minerals (SWM). | ||||||||||||||||||||

Geology | · Deposit type, geological setting and style of mineralisation. | · The geology of the Redmoor Project is typical of other established mining areas of Cornwall. Tin, tungsten and metal sulphide mineralisation is spatially related to granite intrusions which have caused mineral containing fluids to transport and deposit tin, tungsten and copper bearing minerals along fractures and faults in surrounding rocks. · At Redmoor the mineralisation occurs both in discrete veins (lodes) and within a stockwork and sheeted zone of numerous closely spaced quartz veins known as the Sheeted Vein System (SVS). | ||||||||||||||||||||

Drill hole Information | · A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes: o easting and northing of the drill hole collar o elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar o dip and azimuth of the hole o down hole length and interception depth o hole length. · If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case. | CRL 2025 drilling · Drillhole collar data including position, RL, azimuth, inclination, and length is provided below for CRD033:

CRL 2018 drilling · Drillhole collar data including position, RL, azimuth, inclination, and length was provided in the CRL release dated 24 January 2019. CRL 2017 drilling · Drillhole collar data including position, RL, azimuth, inclination, and length were reported in the CRL releases dated 7 September, 1 November, and 11 December 2018. · Depths of intercepts were reported in the releases dated 7 September, 1 November, and 11 December 2018. · Figures previously presented in the 26 November 2015 announcement show the relative location and orientation of the drilling completed by SWM. | ||||||||||||||||||||

Data aggregation methods | · In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated. · Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. · The assumptions used for any reporting of metal equivalent values should be clearly stated. | CRL 2025 drilling · Weighted average intercepts were calculated using sample weighting by length of sample interval. · No high cut was thought to be appropriate. · Internal dilution is accepted where a geological basis is thought to exist for reporting a wider package, for example within the SVS. · For the 2025 drilling, results are expressed in WO3 equivalent values. The formula used is WO₃Eq = WO₃ + (Sn × 0.82) + (Cu × 0.27). · The assumptions for this calculation are:

| ||||||||||||||||||||

Relationship between mineralisation widths and intercept lengths | · These relationships are particularly important in the reporting of Exploration Results. · If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. · If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg 'down hole length, true width not known'). | CRL drilling · The SVS mineralisation is interpreted to be a broad tabular mineralised zone with an internal plunge component, which is currently being evaluated. · The orientation of the drilling is believed to be appropriate for the evaluation of this geometry as presently understood. It is recommended that this be further assessed during subsequent drilling. · Intercepts are reported as apparent thicknesses except where otherwise stated. SWM drilling · Full intersections are available in all cases so there should be no material bias and the differences between intersected and true lode widths were accounted for in consultant SRK's evaluation procedures. | ||||||||||||||||||||

Diagrams | · Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views. | · Appropriate maps, plans, sections and other views of the interpreted mineralisation are included in the announcement. | ||||||||||||||||||||

Balanced reporting | · Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. | · The announcement presents all of the salient exploration data that supports the results presented and where summarised is done so in such a way as to convey all of the results in a balanced manner. | ||||||||||||||||||||

Other substantive exploration data | · Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. | · All relevant new information has been presented in the announcement. | ||||||||||||||||||||

Further work | · The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling). · Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. | · The announcement summarises the geological and other work currently underway and planned and the current considerations regarding the potential of the licence area. |

Related Shares:

Strategic Minerals