5th Jan 2026 12:00

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

05 January 2026

GEO Exploration Limited

("GEO " or the "Company")

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

JORC Code, 2012 Edition - Table 1 report

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

Criteria | JORC Code explanation | Commentary |

Sampling techniques | · Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. · Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. · Aspects of the determination of mineralisation that are Material to the Public Report. · In cases where 'industry standard' work has been done this would be relatively simple (eg 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information. | · All drilling and sampling was undertaken in an industry standard manner · All drill core was sampled as 1m intervals · Half core was crushed and pulverized for analysis · 25g fire assay ICPOES - Au (FA25/OE04) · 4 acid digest ICPMS 48 elements (4A/MS48) |

Drilling techniques | · Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). | · HQ3 and NQ2 core standard tube · Survey between 15m and 60m intervals · Holes vertical |

Drill sample recovery | · Method of recording and assessing core and chip sample recoveries and results assessed. · Measures taken to maximise sample recovery and ensure representative nature of the samples. · Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. | · Minimal core loss reported · Samples are considered representative with good recovery · No sample bias observed |

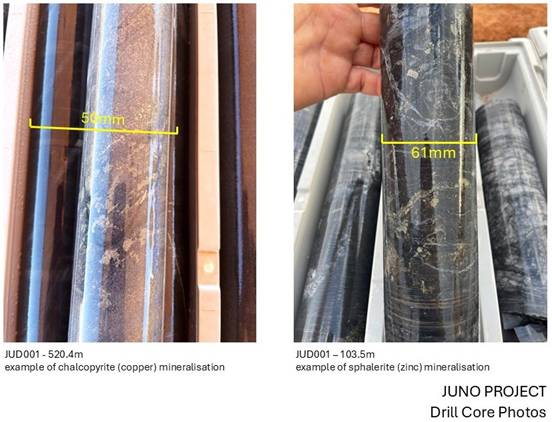

Logging | · Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. · Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. · The total length and percentage of the relevant intersections logged. | · Geologically logged qualitatively as sub metre intervals · All core trays photographed |

Sub-sampling techniques and sample preparation | · If core, whether cut or sawn and whether quarter, half or all core taken. · If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. · For all sample types, the nature, quality and appropriateness of the sample preparation technique. · Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. · Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling. · Whether sample sizes are appropriate to the grain size of the material being sampled. | · All core sawn half and sampled as 1m intervals · All core sampled, crushed and pulverised · Sampling considered appropriate for grain size of material · Sample standards, blanks and duplicates performed by laboratory |

Quality of assay data and laboratory tests | · The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. · For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. · Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established. | · The samples were submitted to a commercial independent laboratory in Perth, Australia (Intertek) · 1m samples were analysed 25g fire assay ICPOES - Au (FA25/OE04), 4 acid digest ICPMS 48 elements (4A/MS48) · The techniques are considered quantitative in nature · Laboratory provides standards, blanks and duplicates · The standards are considered satisfactory |

Verification of sampling and assaying | · The verification of significant intersections by either independent or alternative company personnel. · The use of twinned holes. · Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. · Discuss any adjustment to assay data. | · Sample results reviewed by the Company's consultants · No adjustments have been made to the assay data |

Location of data points | · Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. · Specification of the grid system used. · Quality and adequacy of topographic control. | · Core hole collar locations located by handheld GPS to an accuracy of 4m. · Elevation data Lidar controlled for GPS location · Locations are given in GDA94 Zone 50 projection |

Data spacing and distribution | · Data spacing for reporting of Exploration Results. · Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. · Whether sample compositing has been applied. | · The two core holes are located 825m apart and are considered early stage exploration · Sample compositing has not been applied |

Orientation of data in relation to geological structure | · Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. · If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. | · The core drilling is considered at high angle to geological dip, but may be at low angle to regional and local structural features · The two core holes are considered early stage exploration and the relationship between mineralized structures and drilling orientation is unknown |

Sample security | · The measures taken to ensure sample security. | · All core palletised and plastic shrink wrapped prior to transport to laboratory. |

Audits or reviews | · The results of any audits or reviews of sampling techniques and data. | · No audits have been completed. · Review of laboratory QAQC data has been carried out by geological consultants |

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

Criteria | JORC Code explanation | Commentary |

Mineral tenement and land tenure status | · Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. · The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. | · All drilling located within E08/3497 owned by Juno Gold Pty Ltd 80% and Callum Baxter 20%. · Juno Gold Pty Ltd a 100% subsidiary of Geo Exploration Limited · Native Title Agreement with Jidi Jidi Aboriginal Corporation executed |

Exploration done by other parties | · Acknowledgment and appraisal of exploration by other parties. | · Historical Exploration predominantly carried out by Pasminco Exploration between 1993-1996 · Pasminco targeted shallow SEDEX/Stratiform zinc mineralisation · HD001 core hole by Pasminco 1993 targeted large scale magnetic + gravity response |

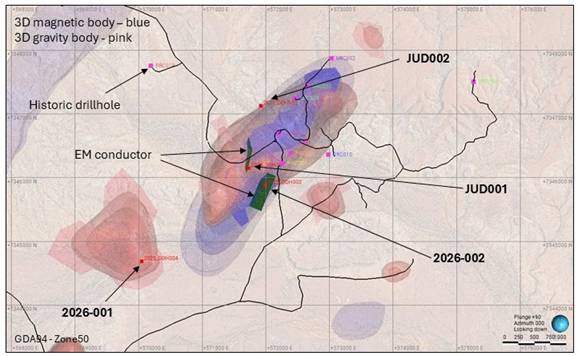

Geology | · Deposit type, geological setting and style of mineralisation. | · Targeted mineralisation - Intrusion Related Gold System (IRGS) · Basement early Proterozoic Capricorn Orogen carbonate rich metasediments with overlying meso-Proterozoic carbonates and shales of Edmund and Collier Basins · Large, kilometre scale magnetic and gravity response at high angle to geological strike |

Drill hole Information | · A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes: - easting and northing of the drill hole collar - elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar - dip and azimuth of the hole - down hole length and interception depth - hole length. · If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case. | · Drill hole location and direction information provided in the report |

Data aggregation methods | · In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated. · Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. · The assumptions used for any reporting of metal equivalent values should be clearly stated. | · No data aggregation methods used in report |

Relationship between mineralisation widths and intercept lengths | · These relationships are particularly important in the reporting of Exploration Results. · If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. · If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg 'down hole length, true width not known'). | · The relationship of the geometry of the mineralisation and drill hole angle is not known

|

Diagrams | · Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views. | · Diagrams in report were prepared to highlight important information relevant to this announcement |

Balanced reporting | · Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. | · All anomalous results are provided in the body of the report · The report is considered balanced and provided in context |

Other substantive exploration data | · Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. | · Other relevant exploration data has been reported in previous market releases listed below

- Exploration Joint Venture 14 August 2024 - Additional Ownership 16 September 2024 - Commencement of Airborne Geophysical Survey 7 October 2024 - Aeromagnetic Results 14 November 2024 - Gravity Survey - 25 November 2024 - Lidar Acquisition - 9 December 2024 - Lidar Data Delivery - 8 January 2025 - Magnetic and Gravity Data - 16 January 2025 - Exploration Licence Application - 19 February 2025 - Results of Geophysical Modelling - 28 May 2025 - Results of Electrical Geophysics - 24 July 2025 - Drilling Update - 19 September 2025 - Drilling Update - 23 October 2025

|

Further work | · The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling). · Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. | · Further work to include review of analytical data from JUD001 and JUD002 with geological and geophysical information. · Additional drill holes are currently proposed as shown in diagram in report. |

Related Shares:

GEO Exploration Limited