13th Nov 2025 07:00

|

|

13 November 2025

AIM: AAU

ASX: AA2

HIGH-GRADE GOLD IN EXPANSION & INFILL DRILLING AT TAVSAN MINE

Ariana Resources plc (AIM: AAU, ASX: AA2, "Ariana" or the "Company"), the mineral exploration, development and production company with gold project interests in Africa and Europe, provides the following summary of the ongoing drilling programme at Tavsan Mine, western Türkiye (23.5% owned by Ariana).

Highlights:

· Assay results received from the 71-hole programme at Tavsan North Zone, designed to identify resource expansion opportunities and to complete infill drilling.

· Results include the following best intercepts:

o 5.10m @ 7.23g/t Au + 3.61g/t Ag (TAV-D002-25)

o 8.50m @ 3.70g/t Au + 2.09g/t Ag (TAV-D138B-25)

o 7.30m @ 4.02g/t Au + 4.81g/t Ag (TAV-D045-25) including 1.00m @ 21.54g/t Au + 8.31g/t Ag

· Mineralisation now confirmed to extend beyond the current JORC Resource, both at depth and along strike and in areas between planned pits

· Drilling is continuing in the Main and South Zone, and other areas across the Tavsan Mine region.

· A JORC Resource update will be completed at the end of the 15,000m programme at Tavsan, expected in Q3 2026.

To read a pdf version of the announcement, please click here: http://www.rns-pdf.londonstockexchange.com/rns/2675H_1-2025-11-12.pdf

Dr. Kerim Sener, Managing Director, commented:

"This is an excellent set of drilling results from the ongoing Tavsan diamond drilling programme. These results relate to the drilling recently completed in the Tavsan North zone, which will become the next open pit to be developed for the mine. The new data confirms our understanding of the geology and demonstrates the continuity of some higher-grade zones in this area.

"This is expected to facilitate an expansion of the Resource and ultimately the Reserve in this area, as we continue to work towards further increases to the expected total 8-year life of mine at Tavsan. The mine has already been in production from its Main Zone for almost two years and went operational through its heap-leach just last month."

The information contained within this announcement is deemed by the Company to constitute inside information as stipulated under the Market Abuse Regulations (EU) No. 596/2014 as it forms part of UK Domestic Law by virtue of the European Union (Withdrawal) Act 2018 ("UK MAR").

Tavsan North Zone Drilling

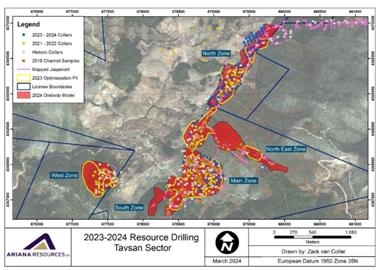

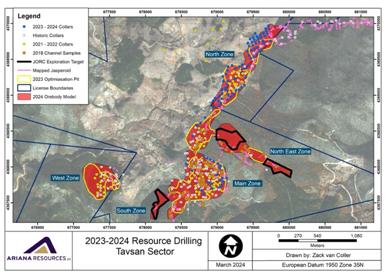

Since the start of drilling at Tavsan early this year, over 9,480m of HQ diamond drilling has been completed by Q3 2025. Of this, 5,345m of drilling was completed across 71 holes at the North Zone (Figure 1), with assay results obtained for all 71 holes as drilling continues, with results expected for other areas of the Tavsan Mine, specifically extensions of the Main and South zones.

Drilling has included infill holes to aid mine planning, but also drilling around the periphery of the currently defined resources, with mineralisation now confirmed to extend beyond the current resource outlines, both at depth and along strike. Tavsan contains a JORC 2012 Measured, Indicated and Inferred Resource of 7.65Mt at 1.26g/t for 311,000oz Au and 1.1Moz Ag. A resource update will be completed at the end of the drilling programme, currently expected in Q3 2026.

Key intercepts to date include:

· 5.10m @ 7.23g/t Au + 3.61g/t Ag from 76.0m in TAV-D002-25

· 8.50m @ 3.70g/t Au + 2.09g/t Ag from 50.7m in TAV-D138B-25

· 7.30m @ 4.02g/t Au + 4.81g/t Ag from 35.8m in TAV-D045-25

o including 1.00m @ 21.54g/t Au + 8.31g/t Ag from 41.5m

· 3.40m @ 5.01g/t Au + 5.44g/t Ag from 39.4m in TAV-D135-25

· 6.70m @ 2.42g/t Au + 1.94g/t Ag from 64.0m in TAV-D057-25

· 1.90m @ 8.41g/t Au + 2.38g/t Ag from 29.8m in TAV-D125-25

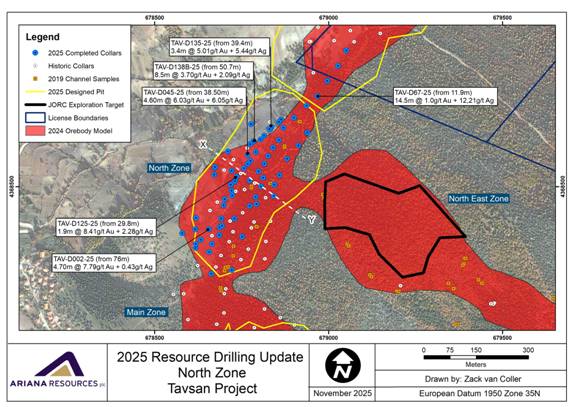

Figure 1: Plan view of Tavsan showing historic and recently completed drilling in the North Zone in relation to the currently defined resources, currently planned pit outlines and target areas.

The infill drilling in North Zone has confirmed the continuity of the high-grade domain, as previously modelled. Gaps in the previous model have also been drilled and have intercepted mineralisation at the expected depths.

The peripheral drilling has indicated a continuation of mineralisation deeper than previously modelled, extending the mineralised zone into an area of 90m (dip) by 200m (strike). Additionally, drilling in the areas between the currently planned pits has shown the continuation of mineralisation across these 50m by 125m gaps.

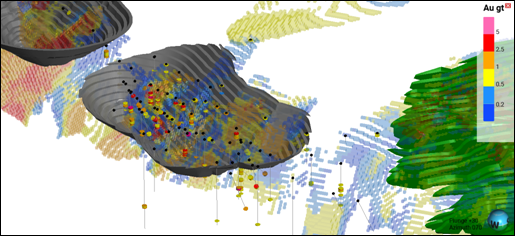

Figure 2: 3D view of Tavsan North Zone showing 2025 drilling within and around the currently planned pits (grey). The March 2024 block model is shown, coloured on the same scale as the assay results. Parts of the Main Zone (green) have been mined already. Drilling and assays are only shown for 2025 for simplicity and only intercepts greater than 0.5g/t Au are shown.

Significant gold intercepts were calculated for the 2025 Tavsan drilling using a 0.5g/t Au minimum cut-off and allowing for up to 1m internal dilution. Intercepts were calculated using Kiziltepe Mine Laboratory ("KML") data. All significant intercepts are provided in JORC Table 1, with intercepts above 5g/t Au x metres, which are considered material to the project listed in the table below.

Figure 3: Northwest-southeast cross-section through Tavsan North Zone, highlighting key 2025 drill intercepts and the geological interpretation for an approximate 200m swath.

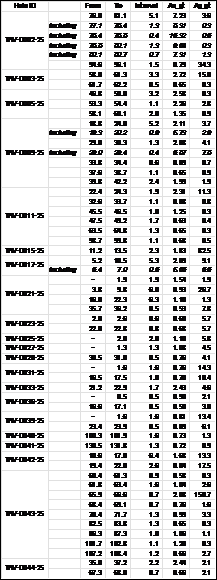

Hole ID | From (m) | To (m) | Interval (m) | Au g/t | Ag g/t |

TAV-D002-25 | 76.0 | 81.1 | 5.1 | 7.23 | 3.61 |

including 77.1 | 78.4 | 1.3 | 8.31 | 0.25 | |

including 78.4 | 78.8 | 0.4 | 16.32 | 0.60 | |

including 78.8 | 80.1 | 1.3 | 9.64 | 0.25 | |

TAV-D003-25 | 58.0 | 61.3 | 3.3 | 2.72 | 14.96 |

TAV-D005-25 | 46.8 | 50.0 | 3.2 | 2.58 | 0.25 |

TAV-D009-25 | 18.8 | 24.0 | 5.2 | 2.11 | 3.69 |

including 19.3 | 20.2 | 0.9 | 5.73 | 2.86 | |

TAV-D017-25 | 5.2 | 10.5 | 5.3 | 2.09 | 9.12 |

TAV-D021-25 | 3.8 | 9.8 | 6.0 | 0.93 | 26.75 |

16.0 | 22.3 | 6.3 | 1.10 | 1.33 | |

TAV-D042-25 | 10.6 | 17.0 | 6.4 | 1.68 | 13.32 |

TAV-D044-25 | 35.0 | 37.2 | 2.2 | 2.44 | 2.06 |

TAV-D045-25 | 35.8 | 43.1 | 7.3 | 4.02 | 4.81 |

including 41.5 | 42.5 | 1.0 | 21.54 | 8.31 | |

TAV-D057-25 | 64.0 | 70.7 | 6.7 | 2.42 | 1.94 |

TAV-D065-25 | 52.5 | 57.2 | 4.7 | 1.13 | 280.82 |

TAV-D067-25 | 11.9 | 26.3 | 14.5 | 1.00 | 12.21 |

TAV-D069-25 | 4.0 | 10.5 | 6.5 | 1.30 | 10.60 |

TAV-D118-25 | 20.4 | 23.8 | 3.4 | 2.04 | 1.15 |

TAV-D125-25 | 29.8 | 31.7 | 1.9 | 8.41 | 2.38 |

including 29.8 | 30.8 | 1.0 | 5.51 | 0.25 | |

including 30.8 | 31.7 | 0.9 | 11.63 | 4.75 | |

TAV-D135-25 | 39.4 | 42.8 | 3.4 | 5.01 | 5.44 |

including 39.4 | 40.7 | 1.3 | 8.37 | 0.25 | |

67.2 | 73.2 | 6.0 | 1.22 | 0.75 | |

75.8 | 81.7 | 5.9 | 1.13 | 1.20 | |

TAV-D138B-25 | 50.7 | 59.2 | 8.5 | 3.70 | 2.09 |

including 50.7 | 51.9 | 1.2 | 9.93 | 1.63 | |

TAV-D139-25 | 37.4 | 41.0 | 3.6 | 1.54 | 11.01 |

Table 1: Significant gold intercepts for the 2025 Tavsan drilling using a 0.5g/t Au minimum cut-off and allowing for up to 1m internal dilution. Only results above 5g/t Au x metres are considered material to the project and are listed here.

Sampling and Assaying Procedures

All diamond drill core from Tavsan has been logged and sampled at the Tavsan Mine site and analysed at the Kiziltepe Mine Laboratory ("KML"), where results are assessed systematically.

HQ-size drill-core samples from the drilling programme at Tavsan were cut in half by a diamond saw and sent for analysis in batches in line with the Company's quality control procedures. Core recovery for all drilling conducted at Tavsan during this 2025 campaign was 88%.

From this programme, a total of 2,476 sample results for 1,818 metres of sampled drill core has been returned from the KML (including 525 QA/QC samples). Samples are also being analysed by ALS Global in Izmir as an external laboratory check as part of the QA/QC procedures used for the project, with a minimum 10% check rate to be achieved by the end of the drilling programme.

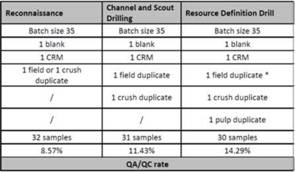

QA/QC sample insertion rates vary depending on the batch size accepted by the laboratory. During the 2021-2025 drilling, Zenit QA/QC protocol required 1 blank, 1 CRM, 1 field duplicate, 1 pulp duplicate and over 10% samples analysed at an external laboratory. Since October 2022, KML has been accredited by the Turkish Accreditation Agency (TÜRKAK) with 'TS EN ISO/IEC 17025:2017 General Requirements for the Competence of Experimental and Calibration Laboratory'.

All samples were assayed for gold using a 30g fire assay. Multi-element ICP was used for analyses of other elements. Reviews of the assay results have determined that all Quality Control and Quality Assurance samples (blanks, standards, field duplicates and pulp duplicates) passed the required quality control checks established by the Company, with duplicate samples showing excellent correlation. Laboratory sample preparation, assaying procedures and chain of custody are appropriately controlled. Zenit maintains an archive of half-core samples and a photographic record of all cores for future reference.

Tavşan Mineral Resource Estimate

MINERAL DOMAIN | CLASSIFICATION | TONNAGE(TONNES) | GRADE | CONTAINED METAL | ||

Au (g/t) | Ag (g/t) | Au (oz) | Ag (oz) | |||

High-grade DomainCut-off: 1.5g/t Au | Measured | 781,800 | 2.53 | 4.32 | 63,600 | 108,600 |

Indicated | 286,700 | 2.46 | 5.72 | 22,700 | 52,700 | |

Inferred | 94,600 | 2.35 | 5.74 | 7,100 | 17,400 | |

TOTAL | 1,163,000 | 2.50 | 4.78 | 93,400 | 178,700 | |

Low-grade DomainCut-off: 0.5g/t Au | Measured | 2,981,600 | 1.04 | 4.86 | 99,900 | 466,300 |

Indicated | 2,131,600 | 1.04 | 3.89 | 71,300 | 266,400 | |

Inferred | 1,373,900 | 1.05 | 4.37 | 46,300 | 192,900 | |

TOTAL | 6,487,100 | 1.04 | 4.44 | 217,600 | 925,700 | |

TOTAL | Measured | 3,763,300 | 1.35 | 4.75 | 163,500 | 574,900 |

Indicated | 2,418,300 | 1.21 | 4.10 | 94,000 | 319,100 | |

Inferred | 1,468,500 | 1.13 | 4.46 | 53,400 | 210,400 | |

TOTAL | 7,650,100 | 1.26 | 4.49 | 311,000 | 1,104,400 | |

Notes:

1. The Tavşan Mineral Resource Estimate is reported in accordance with the JORC Code. Reported using variable cut-off grades of low domain of 0.5g/t Au and high domain of 1.5g/t Au.

2. The Tavşan Mineral Resource Estimate is reported inclusive of Reserves.

3. Refer to sections 5.6.6 and 5.6.7 of the Independent Geologist's Report (IGR) for further information regarding the Tavşan Mineral Resource Estimate including the information required by ASX Listing Rule 5.8.

Tavşan Ore Reserves

CATEGORY | TONNAGE(MT) | GRADE | CONTAINED METAL | ||

Au (g/t) | Ag (g/t) | Au (oz) | Ag (oz) | ||

Proven | 2.5 | 1.46 | 5.02 | 116,400 | 401,100 |

Probable | 2.0 | 1.32 | 4.15 | 84,600 | 266,200 |

TOTAL | 4.5 | 1.40 | 4.63 | 200,900 | 667,300 |

Notes:

1. The Tavşan Ore Reserves are reported in accordance with the JORC Code. Reported using variable cut-off grades of low domain of 0.5g/t Au and high domain of 1.5g/t Au.

2. Refer to section 5.6.8 of the IGR for further information regarding the Tavşan Ore Reserves including the information required by ASX Listing Rule 5.9.

The Board of Ariana has approved this announcement and authorised its release.

Contacts:

Ariana Resources plc Michael de Villiers, Chairman Dr. Kerim Sener, Managing Director | Tel: +44 (0) 20 3476 2080 | |

Beaumont Cornish Limited (Nominated Adviser) Roland Cornish / Felicity Geidt | Tel: +44 (0) 20 7628 3396 | |

| ||

Zeus Capital (Joint Broker) Harry Ansell / Katy Mitchell

Fortified Securities (Joint Broker) Guy Wheatley

Yellow Jersey PR Limited (UK Financial PR) Dom Barretto / Shivantha Thambirajah / Bessie Elliot

M&C Partners (Aus Financial PR) Christina Granger / Ben Henri

Shaw and Partners Limited (Lead Manager - ASX) Damien Gullone

|

| Tel: +44 (0) 203 829 5000

Tel: +44 (0) 203 411 7773

Tel: +44 (0) 7983 521 488

Tel: +61 438 227 286

Tel: +61 (0)2 9238 1268

|

Beaumont Cornish Limited ("Beaumont Cornish") is the Company's Nominated Adviser and is authorised and regulated by the FCA. Beaumont Cornish's responsibilities as the Company's Nominated Adviser, including a responsibility to advise and guide the Company on its responsibilities under the AIM Rules for Companies and AIM Rules for Nominated Advisers, are owed solely to the London Stock Exchange. Beaumont Cornish is not acting for and will not be responsible to any other persons for providing protections afforded to customers of Beaumont Cornish nor for advising them in relation to the proposed arrangements described in this announcement or any matter referred to in it.

About Ariana Resources plc:

Ariana is a mineral exploration, development and production company dual listed on AIM (AIM: AAU) and ASX (ASX: AA2), with an exceptional track record of creating value for its shareholders through its interests in active mining projects and investments in exploration companies. Its current interests include a major gold development project in Zimbabwe, gold-silver production in Türkiye and copper-gold-silver exploration and development projects in Kosovo and Cyprus.

For further information on the vested interests Ariana has, please visit the Company's website at www.arianaresources.com.

Zeus Capital Limited, Fortified Securities and Shaw and Partners Limited are the brokers to the Company and Beaumont Cornish Limited is the Company's Nominated Adviser.

Editors' Note:

The information that relates to Exploration Results are based upon information compiled by Miss Ruth Woodcock, Exploration Group Leader, Ariana Resources plc. Miss Woodcock is a member of Recognised Professional Organisations as defined by JORC 2012: a Chartered Geologist (CGeol, Geological Society of London) and European Geologist (EurGeol, European Federation of Geologists) and has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration and to the activity upon which she is reporting as a Competent Person as defined in the 2012 Edition of "The Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves." Ms. Bektas consents to the inclusion in this report of the matters based on the information compiled by her, in the form and context in which it appears.

Glossary of Technical Terms:

"Au" chemical symbol for gold;

"g/t" grams per tonne;

"JORC" Joint Ore Reserves Committee;

"k" thousand

"km" Kilometres;

"m" Metres;

"M" million

"oz" Troy ounces;

"t" tonnes;

Ends.

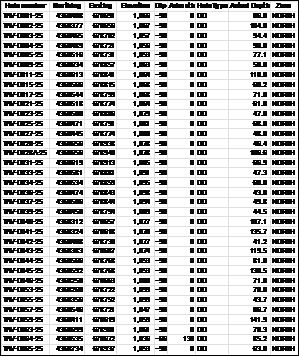

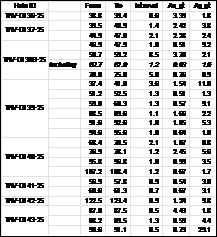

Collars Table for Tavsan North Zone 2025

Hole ID | Easting | Northing | Elevation | Azimuth | Dip | Depth |

TAV-D001-25 | 678691 | 4368408 | 1,066 | 0 | 90 | 86.0 |

TAV-D002-25 | 678656 | 4368377 | 1,067 | 0 | 90 | 104.0 |

TAV-D003-25 | 678702 | 4368465 | 1,057 | 0 | 90 | 94.4 |

TAV-D004-25 | 678721 | 4368489 | 1,056 | 0 | 90 | 90.0 |

TAV-D005-25 | 678731 | 4368516 | 1,053 | 0 | 90 | 77.1 |

TAV-D009-25 | 678857 | 4368634 | 1,063 | 0 | 90 | 50.0 |

TAV-D011-25 | 678841 | 4368613 | 1,064 | 0 | 90 | 110.0 |

TAV-D015-25 | 678815 | 4368566 | 1,068 | 0 | 90 | 60.2 |

TAV-D017-25 | 678799 | 4368544 | 1,068 | 0 | 90 | 71.0 |

TAV-D021-25 | 678774 | 4368518 | 1,064 | 0 | 90 | 61.0 |

TAV-D023-25 | 678806 | 4368500 | 1,079 | 0 | 90 | 47.0 |

TAV-D025-25 | 678791 | 4368471 | 1,081 | 0 | 90 | 68.0 |

TAV-D027-25 | 678774 | 4368445 | 1,080 | 0 | 90 | 48.0 |

TAV-D028-25 | 678938 | 4368656 | 1,078 | 0 | 90 | 46.4 |

TAV-D028A-25 | 678940 | 4368656 | 1,078 | 0 | 90 | 106.6 |

TAV-D031-25 | 678913 | 4368619 | 1,085 | 0 | 90 | 66.9 |

TAV-D033-25 | 678881 | 4368581 | 1,091 | 0 | 90 | 47.3 |

TAV-D034-25 | 678859 | 4368534 | 1,095 | 0 | 90 | 60.0 |

TAV-D036-25 | 678843 | 4368474 | 1,098 | 0 | 90 | 43.0 |

TAV-D037-25 | 678844 | 4368506 | 1,094 | 0 | 90 | 49.8 |

TAV-D039-25 | 678794 | 4368450 | 1,089 | 0 | 90 | 44.5 |

TAV-D040-25 | 678657 | 4368312 | 1,077 | 0 | 90 | 107.1 |

TAV-D041-25 | 678618 | 4368324 | 1,070 | 0 | 90 | 135.7 |

TAV-D042-25 | 678730 | 4368408 | 1,077 | 0 | 90 | 41.2 |

TAV-D043-25 | 678687 | 4368383 | 1,074 | 0 | 90 | 119.5 |

TAV-D044-25 | 678768 | 4368566 | 1,053 | 0 | 90 | 81.0 |

TAV-D045-25 | 678768 | 4368592 | 1,053 | 0 | 90 | 130.5 |

TAV-D046-25 | 678663 | 4368250 | 1,080 | 0 | 90 | 71.0 |

TAV-D053-25 | 678722 | 4368260 | 1,099 | 0 | 90 | 70.0 |

TAV-D055-25 | 678752 | 4368356 | 1,099 | 0 | 90 | 43.7 |

TAV-D057-25 | 678721 | 4368546 | 1,047 | 0 | 90 | 86.7 |

TAV-D059-25 | 678619 | 4368411 | 1,059 | 0 | 90 | 141.9 |

TAV-D063-25 | 678901 | 4368699 | 1,061 | 0 | 90 | 70.3 |

TAV-D064-25 | 678672 | 4368535 | 1,036 | 130 | 66 | 85.2 |

TAV-D065-25 | 678937 | 4368734 | 1,053 | 0 | 90 | 63.0 |

TAV-D066-25 | 678673 | 4368555 | 1,033 | 0 | 90 | 39.3 |

TAV-D066A-25 | 678674 | 4368557 | 1,032 | 0 | 90 | 98.5 |

TAV-D067-25 | 678968 | 4368761 | 1,066 | 0 | 90 | 30.0 |

TAV-D068-25 | 678997 | 4368805 | 1,078 | 0 | 90 | 47.0 |

TAV-D069-25 | 679027 | 4368849 | 1,085 | 130 | 45 | 55.0 |

TAV-D070-25 | 678711 | 4368602 | 1,036 | 0 | 90 | 215.9 |

TAV-D071-25 | 679051 | 4368893 | 1,085 | 130 | 45 | 63.0 |

TAV-D117-25 | 678776 | 4368575 | 1,053 | 125 | 45 | 66.2 |

TAV-D118-25 | 678791 | 4368600 | 1,053 | 120 | 45 | 68.0 |

TAV-D119-25 | 678826 | 4368589 | 1,065 | 120 | 45 | 50.8 |

TAV-D120-25 | 678816 | 4368566 | 1,068 | 120 | 45 | 40.0 |

TAV-D121-25 | 678757 | 4368553 | 1,052 | 125 | 45 | 60.0 |

TAV-D122-25 | 678813 | 4368526 | 1,075 | 120 | 45 | 40.0 |

TAV-D123-25 | 678694 | 4368388 | 1,075 | 115 | 62 | 50.1 |

TAV-D124-25 | 678686 | 4368361 | 1,078 | 115 | 45 | 50.0 |

TAV-D125-25 | 678736 | 4368529 | 1,052 | 125 | 45 | 53.6 |

TAV-D126-25 | 678665 | 4368335 | 1,077 | 110 | 45 | 55.2 |

TAV-D127-25 | 678719 | 4368506 | 1,052 | 125 | 45 | 60.1 |

TAV-D128-25 | 678633 | 4368347 | 1,072 | 110 | 47 | 85.0 |

TAV-D129-25 | 678724 | 4368475 | 1,058 | 120 | 50 | 50.0 |

TAV-D130-25 | 678618 | 4368378 | 1,068 | 110 | 45 | 105.1 |

TAV-D131-25 | 678699 | 4368447 | 1,060 | 120 | 52 | 61.5 |

TAV-D132-25 | 678778 | 4368680 | 1,037 | 120 | 55 | 109.3 |

TAV-D133-25 | 678870 | 4368670 | 1,059 | 120 | 45 | 108.4 |

TAV-D134-25 | 678864 | 4368694 | 1,054 | 120 | 84 | 86.0 |

TAV-D135-25 | 678837 | 4368673 | 1,053 | 120 | 83 | 87.9 |

TAV-D136-25 | 678858 | 4368687 | 1,054 | 120 | 61 | 55.0 |

TAV-D137-25 | 678833 | 4368666 | 1,053 | 120 | 61 | 73.0 |

TAV-D138-25 | 678785 | 4368631 | 1,047 | 120 | 45 | 16.7 |

TAV-D138A-25 | 678830 | 4368667 | 1,053 | 120 | 45 | 20.3 |

TAV-D138B-25 | 678784 | 4368631 | 1,047 | 120 | 45 | 84.3 |

TAV-D139-25 | 678815 | 4368647 | 1,052 | 115 | 62 | 112.5 |

TAV-D140-25 | 678805 | 4368636 | 1,052 | 120 | 86 | 119.6 |

TAV-D141-25 | 678775 | 4368622 | 1,047 | 120 | 72 | 119.6 |

TAV-D142-25 | 678580 | 4368366 | 1,067 | 100 | 63 | 130.1 |

TAV-D143-25 | 678619 | 4368335 | 1,070 | 79 | 59 | 100.0 |

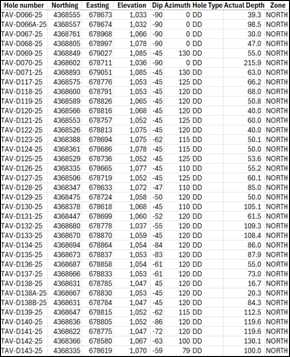

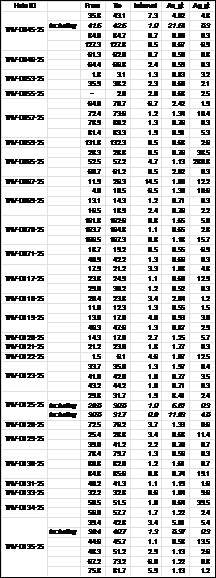

Intercepts Table for Tavsan North Zone

Gold intercepts for the 2025 Tavsan drilling using a 0.5g/t Au minimum cut-off and allowing for up to 1m internal dilution.

Hole ID |

| From | To | Interval | Au g/t | Ag g/t |

TAV-D002-25 | 76.0 | 81.1 | 5.1 | 7.23 | 3.61 | |

including | 77.1 | 78.4 | 1.3 | 8.31 | 0.25 | |

including | 78.4 | 78.8 | 0.4 | 16.32 | 0.60 | |

including | 78.8 | 80.1 | 1.3 | 9.64 | 0.25 | |

including | 80.1 | 80.7 | 0.7 | 7.31 | 1.32 | |

94.6 | 96.1 | 1.5 | 0.79 | 34.33 | ||

TAV-D003-25 | 58.0 | 61.3 | 3.3 | 2.72 | 14.96 | |

61.7 | 62.2 | 0.5 | 0.65 | 0.25 | ||

TAV-D005-25 | 46.8 | 50.0 | 3.2 | 2.58 | 0.25 | |

53.3 | 54.4 | 1.1 | 2.26 | 2.76 | ||

58.1 | 60.1 | 2.0 | 1.35 | 0.86 | ||

TAV-D009-25 | 18.8 | 24.0 | 5.2 | 2.11 | 3.69 | |

including | 19.3 | 20.2 | 0.9 | 5.73 | 2.86 | |

29.0 | 30.3 | 1.3 | 2.88 | 4.11 | ||

including | 29.0 | 29.4 | 0.4 | 6.87 | 7.76 | |

33.8 | 34.4 | 0.6 | 0.89 | 0.67 | ||

37.6 | 38.7 | 1.1 | 0.65 | 0.87 | ||

39.8 | 42.2 | 2.4 | 1.99 | 1.88 | ||

TAV-D011-25 | 22.4 | 24.3 | 1.9 | 2.31 | 11.32 | |

32.6 | 33.7 | 1.1 | 0.88 | 0.77 | ||

45.5 | 46.5 | 1.0 | 1.25 | 0.25 | ||

47.5 | 49.2 | 1.7 | 0.63 | 0.41 | ||

63.5 | 64.8 | 1.3 | 0.65 | 0.25 | ||

98.7 | 99.8 | 1.1 | 0.68 | 0.52 | ||

TAV-D015-25 | 11.2 | 13.5 | 2.3 | 1.83 | 82.49 | |

TAV-D017-25 | 5.2 | 10.5 | 5.3 | 2.09 | 9.12 | |

including | 6.4 | 7.0 | 0.6 | 5.66 | 6.59 | |

TAV-D021-25 | 0.0 | 1.9 | 1.9 | 1.54 | 1.92 | |

3.8 | 9.8 | 6.0 | 0.93 | 26.75 | ||

16.0 | 22.3 | 6.3 | 1.10 | 1.33 | ||

35.7 | 36.2 | 0.5 | 0.53 | 7.83 | ||

TAV-D023-25 | 2.0 | 2.6 | 0.6 | 0.60 | 5.69 | |

22.0 | 22.8 | 0.8 | 0.68 | 5.67 | ||

TAV-D025-25 | 0.0 | 2.0 | 2.0 | 1.10 | 5.82 | |

TAV-D027-25 | 0.0 | 1.3 | 1.3 | 1.08 | 4.45 | |

TAV-D028-25 | 30.5 | 31.0 | 0.5 | 0.76 | 4.06 | |

TAV-D031-25 | 0.0 | 1.6 | 1.6 | 0.76 | 14.34 | |

16.5 | 17.5 | 1.0 | 0.70 | 10.36 | ||

TAV-D033-25 | 21.2 | 22.9 | 1.7 | 2.43 | 4.60 | |

TAV-D036-25 | 0.0 | 0.5 | 0.5 | 0.90 | 2.14 | |

16.6 | 17.1 | 0.5 | 0.50 | 2.99 | ||

TAV-D039-25 | 0.0 | 1.6 | 1.6 | 0.81 | 13.36 | |

23.4 | 23.9 | 0.5 | 0.89 | 6.05 | ||

TAV-D040-25 | 100.3 | 101.9 | 1.6 | 0.73 | 1.31 | |

TAV-D041-25 | 130.5 | 131.8 | 1.3 | 0.72 | 0.92 | |

TAV-D042-25 | 10.6 | 17.0 | 6.4 | 1.68 | 13.32 | |

19.4 | 22.0 | 2.6 | 0.84 | 17.51 | ||

TAV-D043-25 | 60.4 | 61.3 | 0.9 | 0.58 | 0.25 | |

61.8 | 63.4 | 1.6 | 1.04 | 2.58 | ||

65.9 | 66.6 | 0.7 | 2.08 | 150.69 | ||

68.4 | 69.1 | 0.7 | 0.76 | 1.57 | ||

70.4 | 71.7 | 1.3 | 0.99 | 3.33 | ||

82.5 | 83.8 | 1.3 | 0.65 | 0.25 | ||

86.3 | 87.3 | 1.0 | 1.06 | 1.13 | ||

101.7 | 102.8 | 1.1 | 1.20 | 0.25 | ||

107.2 | 108.4 | 1.2 | 0.66 | 2.67 | ||

TAV-D044-25 | 35.0 | 37.2 | 2.2 | 2.44 | 2.06 | |

67.3 | 68.0 | 0.7 | 0.66 | 2.13 | ||

TAV-D045-25 | 35.8 | 43.1 | 7.3 | 4.02 | 4.81 | |

including | 41.5 | 42.5 | 1.0 | 21.54 | 8.31 | |

84.0 | 84.7 | 0.7 | 0.80 | 0.25 | ||

127.3 | 127.8 | 0.5 | 0.67 | 6.93 | ||

TAV-D046-25 | 61.3 | 62.0 | 0.7 | 0.50 | 0.80 | |

64.4 | 66.8 | 2.4 | 0.59 | 0.25 | ||

TAV-D053-25 | 1.8 | 3.1 | 1.3 | 0.83 | 3.18 | |

35.9 | 38.2 | 2.3 | 0.60 | 2.11 | ||

TAV-D055-25 | 0.0 | 2.0 | 2.0 | 0.68 | 2.54 | |

TAV-D057-25 | 64.0 | 70.7 | 6.7 | 2.42 | 1.94 | |

72.4 | 73.6 | 1.2 | 1.34 | 10.42 | ||

78.9 | 80.2 | 1.3 | 0.76 | 0.25 | ||

81.4 | 83.3 | 1.9 | 0.91 | 5.28 | ||

TAV-D059-25 | 131.8 | 132.3 | 0.5 | 0.68 | 2.64 | |

TAV-D065-25 | 28.3 | 28.8 | 0.5 | 0.76 | 38.49 | |

52.5 | 57.2 | 4.7 | 1.13 | 280.82 | ||

60.7 | 61.2 | 0.5 | 2.02 | 0.25 | ||

TAV-D067-25 | 11.9 | 26.3 | 14.5 | 1.00 | 12.21 | |

TAV-D069-25 | 4.0 | 10.5 | 6.5 | 1.30 | 10.60 | |

13.1 | 14.3 | 1.2 | 0.71 | 0.25 | ||

16.5 | 18.9 | 2.4 | 0.76 | 2.22 | ||

TAV-D070-25 | 161.8 | 162.6 | 0.8 | 1.65 | 5.00 | |

163.7 | 164.8 | 1.1 | 0.65 | 2.75 | ||

166.5 | 167.3 | 0.8 | 1.18 | 15.66 | ||

TAV-D071-25 | 18.7 | 19.2 | 0.5 | 0.55 | 6.93 | |

40.9 | 42.2 | 1.3 | 0.66 | 0.25 | ||

TAV-D117-25 | 17.9 | 21.2 | 3.3 | 1.08 | 4.78 | |

23.8 | 24.9 | 1.1 | 0.60 | 12.88 | ||

29.0 | 30.2 | 1.2 | 0.52 | 0.25 | ||

TAV-D118-25 | 20.4 | 23.8 | 3.4 | 2.04 | 1.15 | |

TAV-D119-25 | 11.0 | 12.3 | 1.3 | 0.55 | 1.51 | |

13.0 | 17.0 | 4.0 | 0.93 | 2.96 | ||

46.3 | 47.6 | 1.3 | 0.87 | 2.88 | ||

TAV-D120-25 | 14.3 | 17.0 | 2.7 | 1.25 | 5.73 | |

TAV-D121-25 | 21.2 | 23.0 | 1.8 | 1.77 | 0.25 | |

TAV-D122-25 | 1.5 | 6.1 | 4.6 | 1.07 | 12.47 | |

TAV-D123-25 | 33.7 | 35.0 | 1.3 | 1.97 | 0.41 | |

41.0 | 42.0 | 1.0 | 0.77 | 3.46 | ||

43.2 | 44.2 | 1.0 | 0.71 | 0.25 | ||

TAV-D125-25 | 29.8 | 31.7 | 1.9 | 8.41 | 2.38 | |

including | 29.8 | 30.8 | 1.0 | 5.51 | 0.25 | |

including | 30.8 | 31.7 | 0.9 | 11.63 | 4.75 | |

TAV-D128-25 | 72.5 | 76.2 | 3.7 | 1.33 | 0.56 | |

TAV-D129-25 | 25.4 | 28.8 | 3.4 | 0.68 | 11.35 | |

39.0 | 41.2 | 2.2 | 0.70 | 0.70 | ||

TAV-D130-25 | 78.4 | 79.7 | 1.3 | 0.56 | 0.25 | |

80.8 | 82.0 | 1.2 | 1.61 | 0.72 | ||

84.8 | 85.6 | 0.8 | 0.74 | 19.09 | ||

TAV-D131-25 | 40.2 | 41.3 | 1.1 | 1.19 | 1.61 | |

TAV-D133-25 | 32.2 | 32.8 | 0.6 | 1.04 | 9.64 | |

TAV-D134-25 | 50.5 | 51.5 | 1.0 | 0.64 | 39.49 | |

56.0 | 57.7 | 1.7 | 1.22 | 2.41 | ||

TAV-D135-25 | 39.4 | 42.8 | 3.4 | 5.01 | 5.44 | |

including | 39.4 | 40.7 | 1.3 | 8.37 | 0.25 | |

44.6 | 45.7 | 1.1 | 0.58 | 13.50 | ||

48.3 | 51.2 | 2.9 | 1.13 | 2.59 | ||

67.2 | 73.2 | 6.0 | 1.22 | 0.75 | ||

75.8 | 81.7 | 5.9 | 1.13 | 1.20 | ||

TAV-D136-25 | 38.8 | 39.4 | 0.6 | 3.39 | 1.82 | |

TAV-D137-25 | 39.5 | 40.9 | 1.4 | 2.42 | 3.82 | |

44.9 | 47.0 | 2.1 | 2.28 | 2.40 | ||

TAV-D138B-25 | 46.9 | 47.9 | 1.0 | 0.51 | 9.20 | |

50.7 | 59.2 | 8.5 | 3.70 | 2.09 | ||

including | 50.7 | 51.9 | 1.2 | 9.93 | 1.63 | |

70.0 | 75.0 | 5.0 | 0.76 | 0.93 | ||

TAV-D139-25 | 37.4 | 41.0 | 3.6 | 1.54 | 11.01 | |

51.2 | 52.5 | 1.3 | 0.51 | 1.29 | ||

59.0 | 60.3 | 1.3 | 0.57 | 9.12 | ||

88.5 | 89.6 | 1.1 | 1.66 | 2.17 | ||

91.6 | 92.6 | 1.0 | 1.85 | 5.30 | ||

94.6 | 95.6 | 1.0 | 0.64 | 0.98 | ||

TAV-D140-25 | 68.4 | 70.5 | 2.1 | 1.07 | 0.83 | |

76.9 | 78.1 | 1.2 | 2.45 | 5.64 | ||

95.8 | 96.8 | 1.0 | 0.99 | 3.54 | ||

107.2 | 108.4 | 1.2 | 0.67 | 1.69 | ||

TAV-D141-25 | 56.9 | 57.8 | 0.9 | 0.54 | 3.04 | |

60.6 | 61.3 | 0.7 | 0.67 | 3.06 | ||

TAV-D142-25 | 122.5 | 123.4 | 0.9 | 1.24 | 9.79 | |

TAV-D143-25 | 87.0 | 87.5 | 0.5 | 4.43 | 1.80 | |

88.2 | 89.5 | 1.3 | 0.59 | 4.43 | ||

90.6 | 91.1 | 0.5 | 0.79 | 29.05 |

Editors' Note:

The information that relates to Exploration Results are based upon information compiled by Miss Ruth Woodcock, Exploration Group Leader, Ariana Resources plc. Miss Woodcock is a member of Recognised Professional Organisations as defined by JORC 2012: a Chartered Geologist (CGeol, Geological Society of London) and European Geologist (EurGeol, European Federation of Geologists) and has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration and to the activity upon which she is reporting as a Competent Person as defined in the 2012 Edition of "The Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves." Ms. Bektas consents to the inclusion in this report of the matters based on the information compiled by her, in the form and context in which it appears.

Glossary of Technical Terms:

"Au" chemical symbol for gold;

"g/t" grams per tonne;

"Global Resources" Total project resources, both contained within pits and outside, including mineralisation with potential for underground development;

"JORC" Joint Ore Reserves Committee;

"k" thousand

"km" Kilometres;

"m" Metres;

"M" million

"oz" Troy ounces;

"t" tonnes;

Ends.

JORC Table 1 - Tavsan

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

Criteria | JORC Code explanation | Commentary |

Sampling techniques | · Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. · Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. · Aspects of the determination of mineralisation that are Material to the Public Report. · In cases where 'industry standard' work has been done this would be relatively simple (eg 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information. | · Reverse circulation (RC) chips were collected at 1 m intervals and in some cases over 0.5 m intervals over the mineralised zone. The chips were collected into plastic sample bags from a cyclone to ensure maximum recovery. The samples were split using a standard riffle-splitter to around 0.25 to 0.5 kg per sample. · Diamond drill core is cut using a diamond rock saw, and half-core samples are taken in lithologically appropriate intervals, ranging from 0.5 m to 3 m in length, with additional sampling extending before and after mineralisation. Diamond core void of mineralisation was not a priority for the company and therefore not all core has been sampled once mineralisation controls were established. Core recovery is recorded into the database. For diamond core duplicate sample analysis, half core samples were cut into two quarter core samples, one as the primary sample and the other for duplicate analysis. Half core always remains in the core box. · Samples from the initial exploration programmes were sent to an ISO accredited ALS Chemex in Vancouver, British Columbia for Au and Ag analysis by fire assay and latterly to a similar ALS laboratory in Izmir, which is still used as an external laboratory for QA/QC purposes. · Samples are now prepared and analysed at Zenit's own internal Kiziltepe Mine Laboratory, for Au (fire assay), Ag (AAS), and 4-acid digest for all other elements. · Under normal operational procedures, sampling undertaken during early-stage exploration or reconnaissance is submitted to the laboratory for 30g fire assay analysis. However, sampling undertaken on more advanced or resource stage projects are submitted for 50 g fire assay analysis, where it is expected that the larger sample mass will provide marginally more representative results. · As of January 2022, the Kiziltepe Mine Laboratory houses two ICP-OES (PerkinElmer Avio 550 and PerkinElmer Optima 8000) instruments, two Atomic Absorption Spectrometers (PerkinElmer's PinAAcle 900F), three drying ovens, three crushers, three pulverisers and seven furnaces. In addition, since October 2022 the Kiziltepe Mine Laboratory has been accredited by the Turkish Accreditation Agency (TÜRKAK) with "TS EN ISO/IEC 17025:2017 General Requirements for the Competence of Experimental and Calibration Laboratories". · Portable X-ray Fluorescence (pXRF) analysis is typically used on 1m intervals on all drill core not sampled for assaying. This is primarily for geological modelling purposes. · Some pulp rejects from assayed samples are also analysed using pXRF analysis. This data is not used for mineral resource estimation purposes, but rather for internal evaluations conducted by the exploration team. pXRF certified reference standards are used on a regular basis in line with company procedures. · Rock-saw channel sampling was completed in early 2020 over 60 outcrops of mapped mineralised jasperoid to support the resource. A petrol powered dual bladed diamond saw was used to cut 35 millimetre (mm) thick channels to represent halved HQ core. · Historic drilling and sampling procedures (pre-2000) were not available, but work undertaken was completed by reputable exploration companies, so it is assumed that sampling was completed in line with industry standards at the time. This data amounts to less than 15% of the drilling database to date. In 2008 Ariana Resources successfully completed check assaying of 42 coarse reject material samples to test historical drilling to provide additional confidence to historical Quality Assurance and Quality Control (QA/QC) procedures. |

Drilling techniques | · Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). | · In total 26,074.7 m of drilling across 480 drill holes has been completed across the Tavsan deposit. Additionally 1,169 m has been sampled across 156 rocksaw channels. · Diamond drillholes comprise a combination of PQ and HQ diameter (standard tube). Drilling on the project can be summarised as follows: o 2025 - 71 diamond holes for 5,345.0 m (Tavsan North to 17 October 2025) o 2024 - 3 diamond holes for 741.4 m o 2023 - 99 diamond holes for 7,808.2 m o 2022 - 61 diamond holes for 4,037.2 m o 2021 - 71 diamond holes for 2,173.7 m o 2019 - 4 diamond holes for 90.5 m (Tavsan Far North) o 2006 - 87 RC (13.3 centimetre) holes for 1,611 m o 2004 - 35 PQ diamond holes for 1,419 m o 1997 - 8 diamond holes for 341m, 7 RC holes for 543 m o 1988 - 34 RC holes for 1,965 m · All historic holes were drilled by Ranger (1988), Teck Cominco (1997) and, Pusula Madencilik (Odyssey's 100% Turkish subsidiary) and their various contractors prior to the acquisition of the project by Ariana Resources plc and latterly Zenit Madencilik San. ve. Tic. A.Ş. |

Drill sample recovery | · Method of recording and assessing core and chip sample recoveries and results assessed. · Measures taken to maximise sample recovery and ensure representative nature of the samples. · Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. | · Diamond drillcore recoveries were monitored and recorded into the sampling database. No recovery was calculated for RC drilling conducted at Tavsan. · Select historic drill holes were examined for core recovery at the site, which was deemed to be satisfactory. · Overall core recovery for 2021/2022 diamond drilling was 88% for 2,854 measurements, with 95% of drilling showing over 70% recovery. Core recovery for the 2023 diamond drilling programme was 89%, with 94 % drilling showing over 70% recovery. Core recovery for the 2025 drilling programme to date is 88% (Tavsan North Zone). · There is no correlation between sample recovery and grade. |

Logging | · Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. · Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. · The total length and percentage of the relevant intersections logged. | · All diamond core holes were logged lithologically (regardless of the presence of mineralisation) using a coded logging system for rock type, mineralisation, grain size, colour, alteration and any other relevant observations. · Mineralised zones were identified from observation of mineralogy and lithological characteristics. Portable XRF analysis was conducted post drilling, to provide supporting geochemical data for non-sampled regions in all drilling prior to 2023. Areas identified as geochemically anomalous by pXRF were further sampled. The pXRF was calibrated with the calibration disks on a regular basis. · Logging is qualitative in the comments section and quantitative (scales 1 to 3 or percentages) in the attributes such as alteration or mineralisation. · Logging of RC samples was carried out on washed samples with geological characteristics recorded to a database. · All diamond drill core trays are photographed (dry and wet) before sampling. Representative samples of RC chips are taken for each trip tray and photographed. |

Sub-sampling techniques and sample preparation | · If core, whether cut or sawn and whether quarter, half or all core taken. · If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. · For all sample types, the nature, quality and appropriateness of the sample preparation technique. · Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. · Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling. · Whether sample sizes are appropriate to the grain size of the material being sampled. | · Core samples were cut using an electric circular diamond saw with water supply for dust suppression. Half core remains in the core tray for reference. · RC sampling: Samples were collected at 1 m intervals and split using a two-stage riffle splitter, running each sample through the splitter twice. Wet intervals were sub-sampled with scoop or spear. Samples were oven-dried at the laboratory if necessary. Although every metre was sampled from top to bottom of each hole, metres which were clearly unmineralised were not assayed. · Sample preparation technique is appropriate to the mineralisation style. · Splitting and sample preparation conducted on samples at the Kiziltepe Mine Laboratory: o Drying at 105°C o Crushing whole sample to ≤2 mm o Splitting of crushed sample to analyse o Pulverising sub-sample to 80% passing ≤75 μm |

Quality of assay data and laboratory tests | · The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. · For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. · Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established. | · A quality control (QA/QC) programme was instituted at the beginning of the drill programmes, which consisted of inserting a field duplicate and uncertified/certified reference material samples into the sample stream. No field blanks were inserted. Uncertified standards were typically inserted (1:16 to 1:20 samples), during Odyssey's drilling campaigns. These were determined to not be reliable enough to measure accuracy at the laboratory. Odyssey's own QA/QC programme has significant shortcomings, but the lab performance is adequate to support a mineral resource estimation. Standard and duplicate samples for QA/QC were taken by ALS Izmir and performance was noted as good. Reporting of ALS's internal QA/QC samples have found the results to fall within the 95% confidence interval assigned to them, as per the lab's internal monitoring standards. · All suitable measures were taken to ensure that samples were suitably representative. · QA/QC procedures employed in all drill programmes prior to 2019 included the insertion of certified reference standards (1:22), blank samples (1:22), pulp and crush duplicates (2:22) to monitor the accuracy and precision of laboratory data when samples were submitted to ALS Global, Izmir. Insertion rate of 18%. · In drill programmes since 2019, samples have been submitted in batches of 35 to ALS Global, Izmir, to include 1 blank, 1 CRM, 1 field duplicate and 1 pulp duplicate. Insertion rate of 11%.

· Since 2019, samples have been submitted to Kiziltepe Mine Laboratory in batches of 20 to include 1 field blank, 1 CRM, 1 field duplicate and 1 pulp duplicate. Insertion rate of 20%. The Kiziltepe Mine Laboratory adds an additional duplicate sample which is a split of the 19th sample of each batch. Further to this the laboratory adds 4 internal standards for their own instrumental QA/QC checks. · In addition to routine QA/QC procedures, 59% of all Tavsan drill samples from the 2021/2022 programme were duplicated to submit to ALS Global, Izmir, as check samples at an external laboratory to confirm internal Kiziltepe Mine Laboratory results, whilst the laboratory expansion was taking place and while laboratory procedures and instrumentation was being checked internally. For the 2023 programme, 10% of all drill samples were duplicated to submit to ALS Global, Izmir, as check samples at an external laboratory to confirm internal Kiziltepe Mine Laboratory results. · The overall quality of QA/QC procedures is considered adequate to ensure the validity of the data used for resource estimation purposes. · The handheld portable XRF is an Olympus Vanta. A series of 10 blank and certified reference material samples are used to check the quality of the pXRF data. These are scanned at a rate of 1 blank and 1 CRM for every 100 samples. The device does not require further calibration. |

Verification of sampling and assaying | · The verification of significant intersections by either independent or alternative company personnel. · The use of twinned holes. · Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. · Discuss any adjustment to assay data. | · Significant intercepts were inspected by Mr. Joe Hirst (Tetra Tech Competent Person) during the site inspection in 2018. Data input has been completed in accordance with company procedures, which have been reviewed by Tetra Tech during their MRE in 2018 and 2020. · Data verification was also independently completed in 2006 by Mr. Antoine Yassa of P & E Mining Consultants Inc. during an earlier phase of exploration. 12 check samples were taken. Results were deemed satisfactory and demonstrated that the grade of gold is very similar in most instances, to what was originally reported by Odyssey. · Prior to resource estimation, below detection limit assay results have been replaced with values of zero. · Primary data, data entry procedures, data verification and data storage protocols are in line with industry best-practice. · All samples (30 g or 50 g) are analysed using fire assay with AAS (Au-AA23) and aqua regia with ICP-AES (ME-ICP41). · All samples before 2019 were submitted to the internationally accredited laboratory of ALS Global in Izmir, Turkey (ISO 9001:2008 accredited). · Samples taken in 2019 - 2025 have been submitted to Kiziltepe Mine Laboratory (TS EN ISO/IEC 17025:2017 accredited since October 2022), with minimum 10% also selected for check assays at ALS Global in Izmir throughout the sampling programme. Samples are chosen from areas suspected to be mineralised. · Since early 2021 the Kiziltepe Mine Laboratory has undergone expansion to deal with increased sample capacity. Initial verification of assay results from newly installed laboratory instruments is still undergoing internal review. Check results from the external laboratory (ALS Izmir) have been received and reviewed, demonstrating that received assay data and associated QA/QC samples fall within expected levels. Evaluations of incoming check data for the Zenit and ALS laboratories will continue to be assessed. |

Location of data points | · Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. · Specification of the grid system used. · Quality and adequacy of topographic control. | · All collar positions were located initially by hand-held GPS (Garmin Etrex 10 and 30) and later surveyed by a professional surveyor using DGPS equipment. All coordinates are recorded in UTM ED50 35N. · Down hole surveys were not completed at Tavsan as holes were typically drilled vertically. However, drill holes were surveyed, where possible, by open hole methods at 20 m intervals from surface, during a project review in 2015; using a Flexit down hole multi-shot survey device. · All holes were surveyed in the 2021/2022, 2023/2024 and 2025 drilling programmes using a standard Electronic Multi-shot Magnetic survey deviation tool (Devico PeeWee). · Topographic data is collected by DGPS. Additionally, 5 m and 25 m contours were generated from ortho-rectified WorldView satellite imagery. |

Data spacing and distribution | · Data spacing for reporting of Exploration Results. · Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. · Whether sample compositing has been applied. | · The Resource area has been drilled as access allows, resulting in an irregular data spacing, typically between 25 m and 80 m between collars (average collar spacing between all zones is 35 m). · Samples were composited to 1 m prior to estimation. · 281 diamond drill holes (16,611 m), 128 RC drill holes (4,115 m) and 156 rock-saw channels (1,169 m) were used to model the mineralisation in the most recent MRE (March 2024). · Since the MRE, 71 diamond holes has been drilled at Tavsan North Zone for 5,345 m. · Sample compositing has not been applied at the sampling stage. · Sample spacing and distribution is sufficient to establish the geological and grade continuity required for modelling and resource estimation. |

Orientation of data in relation to geological structure | · Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. · If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. | · The mineralisation is primarily outcropping at surface and has been drilled primarily vertically, with full intersections. Some inclined holes have been drilled between -80 and -40 degrees of dip, primarily stepped off from the mineralisation to delineate the edges of the mineralisation at depth. · No sampling bias is observed from the orientation of drilling with regards to the mineralised structures. True thickness with respect to apparent thickness is well understood as most intersections are normal to the mineralisation. · No biases are expected from the drilling direction. |

Sample security | · The measures taken to ensure sample security. | · Samples are stored in a secure location (Balikoy Depot, and more recently the Tavsan mine site) in a clean area free of any contamination. Full chain of custody documentation is used when transferring the samples to the laboratory and has been overseen by the responsible company geologist. · In drilling programmes pre-2019 the measures taken to ensure sample security for samples used for analysis and QA/QC include the following: o Chain of Custody is demonstrated by both Company and ALS Global or Kiziltepe Mine Laboratory in the delivery and receipt of sample materials. o Upon receipt of samples, ALS Global delivers by email to the Company's designated QC Manager, confirmation that each batch of samples has arrived, with its tamper-proof seal intact, at the allocated sample preparation facility. o Any damage to or loss of samples within each batch (e.g., total loss, spillage or obvious contamination), must also be reported to the Company in the form of a list of samples affected and detailing the nature of the problem(s). · In all drilling programmes since 2020, the majority of samples have been analysed by the Kiziltepe Mine Laboratory. Samples are delivered securely from the drill site to the laboratory by the exploration team and are securely held at the laboratory in the fenced off and guarded mine site, with no unauthorised access. |

Audits or reviews | · The results of any audits or reviews of sampling techniques and data. | · In 2020 Tetra Tech reviewed the protocols and procedures adopted and found the various aspects sufficient to support mineral resource estimation. Tetra Tech completed an independent analysis of the QA/QC data completed by Odyssey, and whilst there are shortcomings, the ALS lab QA/QC programme was robust. The data is deemed appropriate for resource estimation. · Ariana has implemented QA/QC programmes covering all aspects of sample location and collection that meets or exceeds the currently accepted industry standards. · Ariana implemented a QA/QC programme based on international best practice during the initial exploration work and subsequent drilling programmes. The company has continued to review and refine the QA/QC programme as these exploration campaigns have progressed. · Zenit continues to implement QA/QC programmes based on international best practice during the drilling programmes. |

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

Criteria | JORC Code explanation | Commentary |

Mineral tenement and land tenure status | · Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. · The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. | · The Tavsan Property consists of four operating licenses owned by Zenit Madencilik San. ve Tic. A.S. ("Zenit") Joint Venture ("JV") with Proccea Construction Co. and Ozaltin Holding A.S. (23.5% owned by Ariana). Licence numbers: o Örencik license no: 12743, due date of 11.06.2029. o Kavaklı license no: 59770, due date of 11.06.2029. o Dağardı license no: 70484, due date of 10.01.2030. o Evciler license no: 72400, due date of 26.01.2035. · In 2008, Ariana acquired the Project for US $500,000 in cash and 3 million shares in the Company at 5 pence per share from Odyssey Resources Limited and a retained royalty of up to 2% on future gold production payable to Teck Resources Limited. This royalty has since been transferred to Sandstorm Gold Ltd. · There are no known impediments to current operations. |

Exploration done by other parties | · Acknowledgment and appraisal of exploration by other parties. | A summary of exploration activities at Tavsan: · 1980s - Initially discovered by Australian company Ranger. · 1988 - Ranger drilled 34 RC holes totalling 1960.5 m in the primary mineralisation zone. Ranger completed no further work. · 1995 - The MTA (Turkish government exploration agency) sampled the primary ore zone. · 1996 - Teck Cominco Ltd acquired the property and conducted several systematic surface sampling programmes yielding an average grade 2.3 g/t Au at surface. · 1997 - Teck Cominco Ltd initiated a 341 m DD programme for 8 holes (TD01 - TD10). 265 samples were sent for Inductively Coupled Plasma (ICP) and fire assay using a 30-gram aliquot. A RC programme totalling 543 m for 7 holes (T05 - T14) was run concurrently with the DD programme. 362 RC chip samples were analysed for gold using fire assay on a 30-gram aliquot. · 2003 - Pusula Madencilik, Odyssey Resources Ltd's 100% owned subsidiary company in Turkey acquired the Tavsan property from Cominco. · 2004 - Odyssey completed the first of a 3-phase drilling programme. Phase 1 totalled 1,067.7 m and consisted of 20 DD holes (OD1 - OD20). Phase 2 consisted of 15 DD holes (OD21 - OD35), totalling 351 m. · 2005 - Odyssey undertook a surface sampling programme on 11 surface-exposed gold mineralised jasperoid zones. · 2006 - Odyssey completed Phase 3 of drilling with the addition of 87 RC holes (ODX36-ODX131) totalling 1,611 m. · 2008 - Ariana Resources acquired the Tavsan project. · 2010 - Tavsan is added into the Zenit portfolio. |

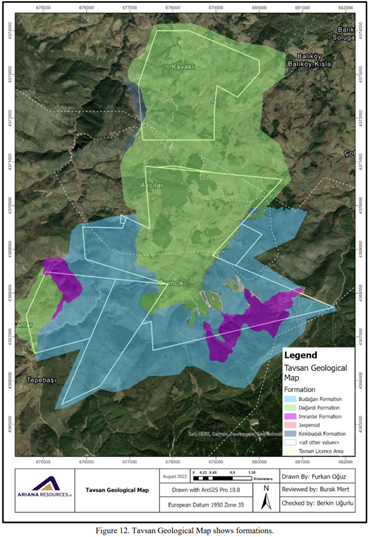

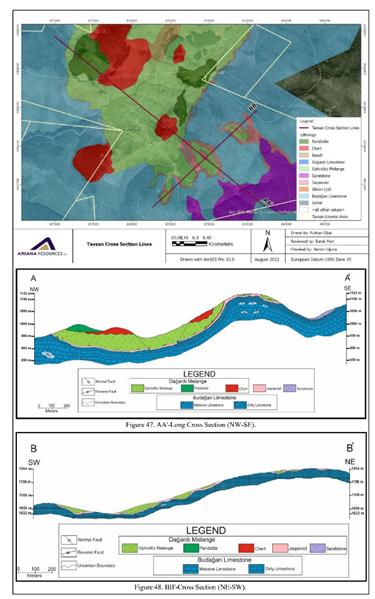

Geology | · Deposit type, geological setting and style of mineralisation. | · The property is located in the Izmir-Ankara suture zone in north-western Anatolia. The formations present span from Jurassic to Tertiary and typically comprise metamorphosed sedimentary sequences, displaying intense compressional tectonic features. · The Property includes an upper thrust plate of Late Cretaceous ophiolitic rocks (Dagardi Melange), jasperoid gold-bearing silicification along the thrust surface and a footwall of Jurassic-Cretaceous Budagan Formation massive, a massive micritic limestone. · Through the summer of 2022, the Ariana team completed remapping of the Tavsan license area to 1:2,000 and 1:5,000 scale (See Diagrams). |

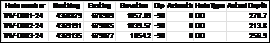

Drill hole Information | · A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes: o easting and northing of the drill hole collar o elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar o dip and azimuth of the hole o down hole length and interception depth o hole length. · If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case. | · No new exploration data is included in this report. All relevant data has been reported in press releases to AIM. · The purpose of the 2019 to 2020 rock-saw channel sampling programme was to provide a further increase in the confidence of the resource classification, and to reduce planned infill drilling meters for future resource development work. The sampling included areas that are were classified as part of the JORC Exploration Target and Inferred Resource, with a view to improving confidence in the resource estimate and an improvement in the resource classification. A total of 751 samples (including 118 QA/QC samples), averaging a length of 1.8 m were extracted during the sampling activities. Of these samples, 676 were sent to the Kiziltepe Mine Laboratory for gold and silver fire assay only. A further 76 samples were sent to ALS in Izmir for gold and silver fire assay and multi-element ICP analysis. The channel sampling makes up only 6% of the drilling database. · Infill resource drilling and exploration drilling was completed in 2022-2023. · 2024 collars:

· 2025 Tavsan North Zone collars:

|

Data aggregation methods | · In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated. · Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. · The assumptions used for any reporting of metal equivalent values should be clearly stated.

| · Metal equivalents have not been used in this estimate. · No aggregation has been applied beyond the standard 1 m sampling interval honouring lithological changes down to 30 cm. · Significant down-hole intercepts for the Tavsan 2025 drilling programme, using a 0.5 g/t Au minimum cut-off and allowing for 1 m internal dilution: |

Relationship between mineralisation widths and intercept lengths | · These relationships are particularly important in the reporting of Exploration Results. · If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. · If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg 'down hole length, true width not known'). | · The majority of the drillholes were advanced vertically. Some holes were advanced at between -80 and -40 degrees from horizontal to intersect dipping structures, or to delineate at depth. The mineralised horizons are commonly flat-lying to gently dipping. As such, the true width is generally represented by the intersection length. However, recorded intercept widths are down hole length and should not be regarded as true widths. · Three-dimensional wireframe models have been generated for sample selection to constrain the resource estimate. This process eliminates any bias imparted by oblique intercepts.

|

Diagrams | · Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views. |

|

Balanced reporting | · Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. | · Full balanced reporting of exploration results has been undertaken and is disclosed within the technical report and press releases to AIM. · Intercepts depths stated in the drill hole information but not stated in the data aggregation methods section are lower grade intersections. Widths of intercepts are stated. |

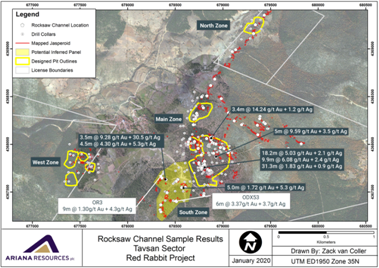

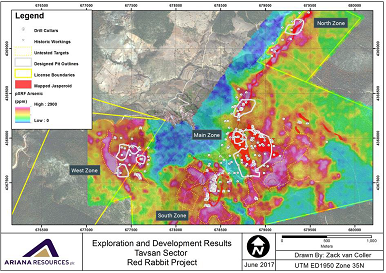

Other substantive exploration data | · Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. | · In 2022 Ariana completed a 41km2 geological mapping project across the Tavsan licenses. This work included pXRF analysis of lithological units, petrography analysis, thin section and magnetic susceptibility studies. · In 2017 Ariana completed an extensive high-resolution (25 m by 25 m) portable X-ray Fluorescence (pXRF) soil survey. This work was completed in order to better define and characterise targets for a second phase of resource-development and to improve confidence in targeting for further resource drilling. Sixteen target areas were highlighted by the 8,265 soil samples collected, covering an area of approximately 5 square kilometres (km2).

|

Further work | · The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling). · Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. | · Further surface sampling and drilling work for Tavsan East Zone. · Further surface exploration to test the anomaly linking West Zone to South Zone. · Further investigation of the deeper high grade intercepts at North Zone.

|

NOTE: Sections 3 and 4 aren't provided here as no mineral resources or ore reserves are being reported. Section 5 is not relevant to this work as there is no estimation or reporting of diamonds or other gemstones in this project.

Related Shares:

Ariana