12th Feb 2026 07:00

8th Floor, 54 Jermyn Street, London, SW1Y 6LX. United Kingdom

Telephone: + 44 (0)20 7629 7772 Facsimile: + 44 (0)20 7629 7773

Email: [email protected]

12th February 2026

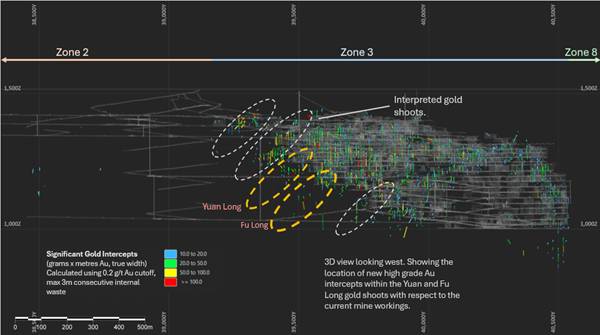

Gold Production, Expansion & Discovery

Griffin Mining Limited ("Griffin" or the "Company) is pleased to announce that gold production has successfully commenced in Zone III of the Yuan Long ("YL") orebody at the Caijiaying Mine, marking the transition into sustained gold production from gold only stopes. Initial stopes are contributing approximately 5-10% of total daily Caijiaying Mine production, establishing gold as a recurring feed source to the processing plant. The YL orebody remains open to the south and at depth, with further diamond drilling and underground development planned to expand the production footprint. Ongoing drilling continues to materially expand the contained gold of the YL system whilst also defining a new, high‑grade, Fu Long ("FL") feeder system, which the Company believes could potentially provide multiple avenues for near‑term growth and longer-term resource expansion.

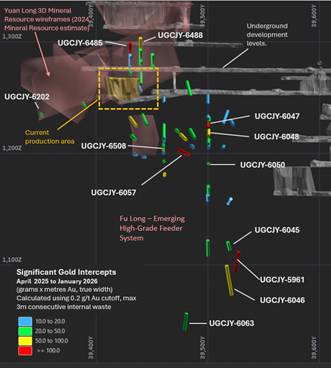

Drilling within the YL orebody continues to return high‑grade gold intercepts, at mineable widths, confirming strong continuity along strike and down‑plunge and supporting ongoing stope development and resource growth. Selected significant true‑width intercepts include:

· UGCJY‑6485: 6.0 m @ 31.5 g/t Au (including 0.6m @ 312g/t)

· UGCJY‑6488: 11.9 m @ 5.3 g/t Au (including 0.6m @ 92 g/t)

· UGCJY‑6202: 6.9 m @ 4.7 g/t Au (including 2.5m @ 11.8 g/t)

These results demonstrate the robust grade, thickness and continuity of the YL gold system.

Drilling within the Fu Long orebody has confirmed the presence of a distinct, high‑grade, feeder system which is interpreted to contribute to the broader YL-FL mineralised corridor. Selected true‑width intercepts include:

· UGCJY 6047: 5.9 m @ 71.2 g/t Au (including 0.8m @ 479.8 g/t, 4.7m @ 2.2 g/t, 13.0m @ 1.0 g/t)

· UGCJY 6508: 9.2 m @ 1.4 g/t Au (including 3.7 m @ 16.1 g/t, 1.0 m @ 53.5 g/t, 11.4m @ 3.6 g/t, 0.9 m @ 34.4 g/t, 4.3m @4.3 g/t)

· UGCJY-5961: 12.2m @ 8.3 g/t Au (including 5.3m @ 16 g/t)

· UGCJY‑6045: 6.8 m @ 5.9 g/t Au (including 0.5m @ 63.6 g/t)

· UCCJY-6048: 13.9m @ 5.8g/t Au (including 2.0 m @ 30.1 g/t, 10.5 m @ 3.7 g/t)

· UGCJY‑6063: 7.9 m @ 5.1 g/t Au

· UGCJY-6050: 15.7m @ 4.6 g/t Au (including 15.7m @ 34.6 g/t, 2.6 m @ 23.2 g/t)

· UGCJY-6057: 29.0m @ 4.0 g/t Au (including 5.1m @ 9.2 g/t)

· UGCJY-6046: 18.4m @ 3.3g/t Au

The identification of this feeder system introduces additional high‑grade gold growth and enhances long‑term production flexibility at the Caijiaying Mine.

Full detail of intercepts are set out further below in this announcement.

Chairman's Statement

Chairman Mladen Ninkov commented, "The continuing success of not only discovering more gold at the Caijiaying Mine, but also incorporating new discoveries into the production profile, confirms the quick nature in which newly discovered gold can be profitably extracted for the benefit of the Company and, ultimately, the shareholders. We look forward to further news in due course."

Further information

Griffin Mining Limited

Mladen Ninkov - Chairman Telephone: +44(0)20 7629 7772

Roger Goodwin - Finance Director

Panmure Liberum Limited - Nominated Adviser & Joint Broker Telephone: +44 (0)20 7886 2500

James Sinclair-Ford

Zak Wadud

Berenberg - Joint Broker Telephone: +44(0)20 3207 7800

Matthew Armitt

Jennifer Lee

This announcement contains inside information for the purposes of Article 7 of the Market Abuse Regulation (EU) No. 596/2014

Griffin Mining Limited's shares are quoted on the Alternative Investment Market (AIM) of the London Stock Exchange (symbol GFM)

The Company's news releases are available on the Company's web site: www.griffinmining.com

Appendix 1: Supporting Diagrams and Tables.

Figure 1. Long section looking west on the left and cross-section looking north on the right. All Yuan and Fu Long significant gold intercept traces (April 2025- January 2026). Significant intercepts are coloured by the sum of grams*metres Au values. 3D views, with semi-transparent Dec 2024 Mineral Resource wireframes (Not all significant intercept traces are annotated with grade information, refer to complete significant intercepts table (Appendix) for full details, and to Figure 2 for location diagram)

Figure 2: Long section looking west. Location of Yuan and Fu Long high-grade gold shoots and April 2025 to January 2026 significant intercepts with respect to current mine development at Caijiaying and previous high grade gold drilling intercepts.

2.1 Detailed significant intercepts table, April 2025 to January 2026, Yuan/Fu Long drilling

Site_ID | East (Mine) | North (Mine) | RL | Azi (Mine) | Dip | DEPTH FROM | Interval (m true width) | Au (g/t) | Au gram * metres (g*m Au) | Zn_% | Location & Comments |

UGCJY-5956 | 5035.2 | 39541 | 1190.8 | 256.3 | 24.2 | 83.8 | 11.5 | 1.3 | 14.9 | 0.59 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-5959 | 5035.1 | 39539.2 | 1190.2 | 258 | -20 | 92.0 | 10.6 | 1.1 | 11.5 | 0.09 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-5961 | 5035.2 | 39541 | 1190.8 | 257.2 | -55 | 98.0 | 12.2 | 8.3 | 100.3 | 0.06 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

incl. | 106.0 | 5.3 | 16.0 | 85.3 | |||||||

UGCJY-6041 | 5043.7 | 39500.8 | 1192.3 | 283.7 | 31.5 | 64.0 | 22.6 | 0.6 | 12.6 | 0.68 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-6042 | 5043.7 | 39500.8 | 1191.6 | 284.5 | 14.8 | 50.2 | 7.6 | 2.6 | 19.5 | 0.06 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-6045 | 5044.5 | 39500.3 | 1189.7 | 284.4 | -44 | 99.3 | 6.8 | 5.9 | 40.4 | 0.01 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

incl. | 99.3 | 0.5 | 63.6 | 33.2 | |||||||

UGCJY-6046 | 5044.8 | 39500.2 | 1189.8 | 285.3 | -54 | 111.0 | 18.4 | 3.3 | 59.9 | 0.40 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

incl. | 138.0 | 2.3 | 17.4 | 39.4 | |||||||

UGCJY-6047 | 5043.8 | 39500.1 | 1192.6 | 270.3 | 38.1 | 49.0 | 5.9 | 71.2 | 417.5 | 0.02 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

Incl. | 49.0 | 0.8 | 479.8 | 401.9 | |||||||

and | 62.0 | 4.7 | 2.2 | 10.1 | 0.02 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | |||||

and | 83.0 | 13.0 | 1.0 | 13.3 | 0.48 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | |||||

UGCJY-6048 | 5043.6 | 39500.1 | 1192.2 | 270.2 | 24.1 | 40.0 | 10.4 | 2.3 | 23.7 | 0.19 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

and | 58.0 | 13.9 | 5.8 | 80.6 | 0.47 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | |||||

Incl. | 60.0 | 2.0 | 30.1 | 59.8 | |||||||

and | 88.5 | 10.5 | 3.7 | 38.6 | 0.24 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | |||||

UGCJY-6049 | 5043.7 | 39499.9 | 1191.3 | 270.4 | 12.2 | 64.7 | 16.1 | 0.9 | 14.5 | 0.17 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

and | 5043.7 | 39499.9 | 1191.3 | 92.0 | 7.6 | 3.8 | 29.2 | 0.01 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | ||

UGCJY-6050 | 5043.7 | 39499.9 | 1191 | 270.4 | -0.2 | 57.0 | 11.3 | 1.9 | 21.1 | 0.06 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

and | 80.9 | 15.7 | 4.6 | 72.5 | 0.03 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | |||||

incl. | 93.3 | 2.6 | 23.2 | 59.8 | |||||||

UGCJY-6051 | 5044 | 39500 | 1190.6 | 84.0 | 26.1 | 1.9 | 48.9 | 0.35 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | ||

UGCJY-6052 | 5044.2 | 39500 | 1190.1 | 270.3 | -25 | 65.0 | 7.7 | 1.7 | 12.9 | 0.01 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-6053 | 5044.2 | 39500 | 1190.1 | 269 | -46 | 95.4 | 11.0 | 1.9 | 20.6 | 0.02 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-6054 | 5043.9 | 39500.1 | 1192.7 | 255.1 | 43.6 | 85.0 | 17.1 | 1.2 | 21.1 | 0.39 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-6055 | 5043.7 | 39500 | 1192.1 | 256 | 25.3 | 50.0 | 18.3 | 2.2 | 40.9 | 0.09 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

incl. | 57.0 | 1.0 | 18.6 | 18.0 | |||||||

UGCJY-6056 | 5043.6 | 39499.9 | 1191.3 | 256.4 | 14.8 | 55.0 | 7.7 | 1.5 | 12.0 | 0.02 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

and | 83.0 | 18.1 | 3.7 | 67.5 | 0.03 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | |||||

incl. | 86.0 | 2.9 | 14.2 | 41.0 | |||||||

and | 110.0 | 7.7 | 2.9 | 22.1 | 0.99 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | |||||

UGCJY-6057 | 5043.6 | 39499.9 | 1191 | 254.8 | 7.1 | 64.0 | 29.0 | 4.0 | 117.4 | 0.02 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

incl. | 92.0 | 5.1 | 9.2 | 46.9 | |||||||

UGCJY-6063 | 5044.8 | 39500 | 1189.7 | 254.7 | -61 | 152.0 | 7.9 | 5.1 | 40.5 | 0.14 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-6192 | 5073.4 | 39459.2 | 1191.8 | 260.7 | 20.2 | 96.0 | 26.7 | 0.9 | 23.9 | 0.08 | Resource Infill Drilling. True thickness (20.4 g*m Inside 2024 Resource, 3.5 g*m Outside 2024 Resource) |

UGCJY-6197 | 5102 | 39418.4 | 1191.9 | 259.9 | 16.9 | 169.0 | 15.4 | 2.7 | 41.5 | 0.62 | Resource Infill Drilling. True thickness (37.9 g*m Inside 2024 Resource, 3.6 g*m Outside 2024 Resource) |

incl. | 170.0 | 1.9 | 18.7 | 35.9 | |||||||

UGCJY-6202 | 5124.5 | 39378.7 | 1192.2 | 260.2 | 13.9 | 173.3 | 6.9 | 4.7 | 32.5 | 0.03 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

incl. | 178.0 | 2.5 | 11.8 | 30.0 | |||||||

UGCJY-6404 | 4947 | 39460.5 | 1273.3 | 89 | -57 | 56.0 | 12.9 | 1.7 | 22.5 | 0.16 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-6406 | 4946.1 | 39450.6 | 1275.7 | 90.8 | 34.4 | 5.0 | 10.5 | 2.5 | 25.8 | 0.08 | Resource Infill Drilling. True thickness (14.9 g*m Inside 2024 Resource, 10.9 g*m Outside 2024 Resource) |

UGCJY-6407 | 4946.1 | 39450.5 | 1275 | 89.5 | 9.4 | 3.9 | 14.7 | 2.5 | 36.4 | 0.12 | Resource Infill Drilling. True thickness (6.5 g*m Inside 2024 Resource, 29.9 g*m Outside 2024 Resource) |

incl. | 7.0 | 1.7 | 11.6 | 20.2 |

| ||||||

UGCJY-6411 | 4944.7 | 39440 | 1276 | 91.1 | 37.4 | 12.0 | 8.6 | 3.2 | 27.4 | 0.14 | Resource Infill Drilling. True thickness (2.1 g*m Inside 2024 Resource, 25.3 g*m Outside 2024 Resource) |

incl. | 22.0 | 1.6 | 13.6 | 22.0 | |||||||

UGCJY-6412 | 4944.7 | 39440 | 1275.4 | 90.6 | 16 | 17.0 | 8.9 | 2.7 | 23.7 | 0.02 | Resource Infill Drilling. True thickness (Entire intercept outside 2024 Resource) |

incl. | 20.0 | 1.3 | 15.8 | 21.0 | |||||||

UGCJY-6413 | 4944.9 | 39439.9 | 1273.7 | 89.5 | -33 | 3.1 | 18.8 | 1.7 | 31.6 | 0.02 | Resource Infill Drilling. True thickness (7.2 g*m Inside 2024 Resource, 24.5 g*m Outside 2024 Resource) |

UGCJY-6416 | 4943.9 | 39430.2 | 1276 | 89.8 | 30.6 | 0.0 | 15.1 | 1.2 | 17.8 | 0.98 | Resource Infill Drilling. True thickness (0.8 g*m Inside 2024 Resource, 17 g*m Outside 2024 Resource) |

UGCJY-6417 | 4944 | 39430.2 | 1274.6 | 88.2 | -11 | 5.2 | 14.0 | 2.4 | 33.1 | 0.07 | Resource Infill Drilling. True thickness (14.2 g*m Inside 2024 Resource, 18.8 g*m Outside 2024 Resource) |

UGCJY-6430 | 4946.6 | 39460.5 | 1273.3 | 89.3 | -70 | 24.3 | 2.2 | 5.3 | 11.8 | 0.07 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-6485 | 4943.7 | 39430.3 | 1276.7 | 16.5 | 6.0

| 31.5 | 188.0 | 0.02 | Resource Infill Drilling. True thickness (10.7 g*m Inside 2024 Resource, 177.3 g*m Outside 2024 Resource) | ||

Incl. | 22.0 | 0.6 | 312.0 | 176.7 | |||||||

UGCJY-6486 | 4944 | 39430.2 | 1274.8 | 89 | 7.3 | 1.7 | 8.8 | 1.5 | 13.6 | 0.52 | Resource Infill Drilling. True thickness (0.4 g*m Inside 2024 Resource, 13.1 g*m Outside 2024 Resource) |

and | 16.6 | 4.8 | 2.8 | 13.5 | 0.27 | Resource Infill Drilling. True thickness (Entire intercept inside 2024 Resource) | |||||

incl. | 16.6 | 0.6 | 15.2 | 9.4 | |||||||

UGCJY-6488 | 4944.4 | 39440 | 1276.6 | 15.0 | 11.9 | 5.3 | 62.8 | 0.17 | Resource Infill Drilling. True thickness (61.2 g*m Inside 2024 Resource, 1.6 g*m Outside 2024 Resource) | ||

incl. | 15.0 | 0.6 | 92.0 | 57.1 | |||||||

UGCJY-6491 | 5073.5 | 39460.3 | 1192.4 | 255 | 18.7 | 100.1 | 23.2 | 2.2 | 51.0 | 0.01 | Resource Infill Drilling. True thickness (50.5 g*m Inside 2024 Resource, 0.5 g*m Outside 2024 Resource) |

incl. | 111.0 | 2.7 | 12.6 | 33.6 | |||||||

UGCJY-6492 | 5073 | 39460.7 | 1191.7 | 255.3 | 11.5 | 104.0 | 16.4 | 1.4 | 22.6 | 0.03 | Resource Infill Drilling. True thickness (3.4 g*m Inside 2024 Resource, 19.4 g*m Outside 2024 Resource) |

UGCJY-6493 | 5072.8 | 39460.7 | 1191.6 | 256.3 | 4 | 70.7 | 7.2 | 1.5 | 11.0 | 0.01 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

and | 103.0 | 9.7 | 2.0 | 19.1 | 0.08 | Resource Infill Drilling. True thickness (Entire Intercept on 2024 Resource Boundary) | |||||

Incl. | 110.0 | 1.0 | 17.0 | 16.4 | |||||||

UGCJY-6507 | 5073.1 | 39460.7 | 1191.7 | 269.5 | 14.2 | 86.0 | 7.8 | 1.6 | 12.5 | 0.04 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-6508 | 5073 | 39460.8 | 1191.6 | 270 | 7.1 | 65.8 | 9.2 | 1.4 | 12.6 | 0.02 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

and | 87.0 | 3.7 | 16.1 | 60.2 | 0.02 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | |||||

incl. | 89.0 | 1.0 | 53.5 | 53.5 | |||||||

and | 105.0 | 11.4 | 3.6 | 41.2 | 0.01 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | |||||

incl. | 110.0 | 0.9 | 34.4 | 30.6 | |||||||

and | 122.3 | 4.3 | 4.3 | 18.3 | 0.26 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) | |||||

UGCJY-6509 | 5072.9 | 39460.6 | 1191.1 | 269.8 | 1.2 | 86.8 | 12.3 | 3.8 | 46.7 | 0.02 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

UGCJY-6599 | 5072.9 | 39460.6 | 1190.9 | 269.9 | -6.3 | 87.0 | 12.5 | 4.3 | 53.3 | 0.05 | Resource Extension Drilling. True thickness (Entire intercept outside 2024 Resource) |

incl. | 90.4 | 4.2 | 8.4 | 34.8 |

Competent Persons' Statements and JORC Compliance Statements

Information in this announcement that relates to new underground diamond drill results is based on and fairly represents information and supporting documentation compiled by Mr Paul Benson (BSc). Mr Benson has over 30 years of industry experience and is a full-time employee of Hebei Hua Ao Mining Industry Company Limited ("Hebei Hua Ao"). Griffin Mining Limited owns a 88% equity interest in Hebei Hua Ao which is the operating Company of the Caijiaying Mine. Mr Benson has been Geology Manager with Griffin Mining Limited and Hebei Hua Ao for more than 9 years and is a Member of the Australian Institute of Mining and Metallurgy (AusIMM). Mr Benson has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (2012 JORC Code). Mr Benson consents to the inclusion in this announcement of all technical statements based on his information in the form and context in which they appear.

JORC Code, 2012 Edition - Table 1

Section 1: Sampling Techniques and Data

Criteria | JORC Code explanation | Commentary |

Sampling techniques | Nature and quality of sampling (e.g. cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as downhole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. | The sample database is made up of surface diamond (DD) and reverse circulation (RC) drilling, underground diamond drilling and representative continuous chip sampling of underground development walls. |

Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. | Diamond core was cut in half using a diamond saw, with the cut line determined by the core orientation line or by mineralisation angles when ori-line is absent. RC samples were split through a riffle splitter. Underground development drive & cross-cut wall samples were collected using a rock hammer with best efforts made to collect representative ~1m samples | |

Aspects of the determination of mineralisation that are Material to the Public Report. In cases where 'industry standard' work has been done this would be relatively simple (e.g. 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases, more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (e.g. submarine nodules) may warrant disclosure of detailed information. | Diamond holes were sampled after standard logging and photography. Sampling intervals were 0.5-1.5 m with 1.0 m being the most common interval. RC drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 50 g charge for fire assay and a 20 g charge for base metal assay. | |

Drilling techniques | Drill type (e.g. core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc.) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc.). | Drilling was completed using a face sampling hammer or NQ2/BQ size diamond core. All holes were surveyed upon completion of drilling using single/multi-shot electronic or mechanical survey cameras. |

Drill sample recovery | Method of recording and assessing core and chip sample recoveries and results assessed. | Core recovery is measured for diamond core by measuring the length of core for each core run. This is recorded in a table called GEOTECH. There is no recovery recorded for RC holes, but these constitute only 50 holes within the Mineral Resource and have been mainly used to provide information about the depth of overburden. There are no RC hole data for the Yuan/Fu Long high-grade gold domain work reported here. |

Measures taken to maximise sample recovery and ensure representative nature of the samples. | Diamond coring is carried out using equipment in good working order to ensure no loss of core. Any core loss during drilling is noted on a core block placed into the core tray and then discussed with the geologist. Core loss is generally rare and related to fault zones away from mineralisation. RC sample recovery was maximised by using a modern rig with sufficient air to keep the hole dry. | |

Relationship between sample recovery and grade/sample bias. | This analysis was not carried out because core recovery has generally been high through the mineralised zones. | |

Logging | Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. | All RC samples were geologically logged to record weathering, regolith, rock type, colour, alteration, mineralisation, structure and texture and any other notable features that are present. All diamond core was logged for structure and geologically logged using the same system as that for RC. The logging information was recorded into Microsoft (MS) Excel format on paper and then transferred into the company's drilling database once the log was complete. Since 2017 core logging has been directly into MS Excel sheets on laptop computers. |

Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. | Logging was qualitative; however, the geologists also record visual quantitative mineral percentage ranges for the sulphide minerals present. Diamond core was photographed wet one core tray at a time using a standardised photography jig. Samples from RC holes were archived in standard 20 m plastic chip trays. | |

The total length and percentage of the relevant intersections logged. | All holes and intersections have been logged. | |

Subsampling techniques and sample preparation | If core, whether cut or sawn and whether quarter, half or all core taken. | Core samples were taken from half core, cut using a diamond core saw. The remainder of the core was retained in core trays tagged with a hole number and metre mark. Since 2016 small diameter (BQ) underground holes (dominantly grade control holes) have been whole core sampled, to remove the need for core cutting and to increase the sample weight. |

If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. | RC samples were cone split to a nominal 2.5 kg to 3 kg sample weight. The drilling method was designed to maximise sample recovery and delivery of a clean, representative sample into the calico bag. Where possible all RC samples were drilled dry to maximise recovery. The use of a booster and auxiliary compressor provide dry sample for depths below the water table. Sample condition was recorded (wet, dry or damp) at the time of sampling and recorded in the database. Samples were collected in a pre-numbered calico bag bearing a unique sample ID. Samples were crushed to 75 µm at the laboratory and riffle split (if required) to a maximum 3 kg sample weight. Gold analysis was determined by a 50 g fire assay with an inductively coupled plasma-optical emission spectrometry (ICP-OES) or atomic absorption spectroscopy (AAS) finish. | |

For all sample types, the nature, quality and appropriateness of the sample preparation technique | The assay laboratories' sample preparation procedures follow industry best practice, with techniques and practices that are appropriate for this style of mineralisation. Pulp duplicates were taken at the pulverising stage and selective repeats conducted at the laboratories' discretion. | |

Quality control procedures adopted for all subsampling stages to maximise representivity of samples. | Cut lines are marked on diamond drill core to ensure that the core to minimise bias when cutting. The RC drilling was carried out several years ago, and no documentation remains on QAQC of subsampling. RC samples are not material to the Mineral Resource estimate (MRE) or to this announcement. | |

Measures taken to ensure that the sampling is representative of the in-situ material collected, including for instance results for field duplicate/second-half sampling. | Hua Ao inserts approximately three standards and three blanks for every 100 samples. Field duplicates were collected from the cone splitter on the rig for RC samples at a frequency of one duplicate every 20 samples, excluding the 100th sample as this was a standard. Diamond core field duplicates are not taken. Regular reviews of the sampling are carried out by the supervising geologist and senior field staff, to ensure all procedures were followed and best industry practice carried out. | |

Whether sample sizes are appropriate to the grain size of the material being sampled. | The sample sizes were appropriate for the type, style and consistency of mineralisation encountered during this phase of exploration. | |

Quality of assay data and laboratory tests | The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. | The assay method and laboratory procedures were appropriate for this style of mineralisation. The fire assay technique was designed to measure total gold in the sample. |

For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. | No geophysical tools, spectrometers were used. Handheld x-ray fluorescence (XRF) instruments are used; however, the values were only used to support geological modelling of the lithology. The values were not used for grade estimation. | |

Nature of quality control procedures adopted and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established. | The QAQC process described above was sufficient to establish acceptable levels of accuracy and precision. All results from assay standards and duplicates were scrutinised to ensure they fell within acceptable tolerances. | |

Verification of sampling and assaying | The verification of significant intersections by either independent or alternative company personnel. | Primary data is sent in digital format to the company's Database Administrator (DBA) as often as was practicable. The DBA imports the data into a GeoBank (MS SQL) database, with assay results merged into the database upon receipt from the laboratory. Once loaded, data was extracted for verification by the geologist in charge of the project. |

The use of twinned holes. | Twinned holes have not been drilled at Caijiaying because the MRE is predominantly based on diamond drillholes with demonstrated good recovery through the ore zones. Several years of production give confidence to the geometry and persistence of mineralisation. | |

Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. | All primary data is collected on paper logs, which are filed and stored. Procedures are documented for data recording and entry. Data from paper logs is transferred to MS Excel files and then imported into GeoBank drillhole database. A back up of the database is maintained in ERM's Perth office. Since 2017, logging has been directly into MS Excel tables on a laptop. These files are transferred to a server. The server has a backup system. | |

Discuss any adjustment to assay data. | No adjustments were made to any current or historical data. If data could not be validated to a reasonable level of certainty it was not used in any resource estimations. | |

Location of data points | Accuracy and quality of surveys used to locate drillholes (collar and downhole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. | Surface RC drill collars were surveyed after completion, using a differential global positioning system (GPS) instrument. Downhole RC surveys were completed using a mechanical single-shot survey camera. Underground holes were surveyed by mine surveyors using a total station theodolite. Downhole surveys were completed using single/multi-shot electronic survey instruments or single-shot survey camera. Downhole surveys are recorded relative to magnetic north. Corrections are made, depending on the year of survey, for magnetic declination, to give azimuths in terms of the Hua Ao mine grid system. |

Specification of the grid system used. | All coordinates and bearings use the Hua Ao mine grid system. | |

Quality and adequacy of topographic control. | The quality of the topographic control is considered to be sufficient. The mine is in operation and has a site-based survey department. Their work is of good quality, supported by development breakthroughs occurring as expected; being able to connect two drives being developed towards each other and so on. | |

Data spacing and distribution | Data spacing for reporting of Exploration Results. | The data spacing is irregular, with a clustering in the main part of the mine, but average spacings are approximately 40 m x 40 m. |

Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. | Refer to December 2024 Mineral Resource estimation report. Resource extension drilling is designed to produce data density suitable for future Mineral Resource estimation updates. | |

Sample compositing | Sample composites have not been used. | |

Orientation of data in relation to geological structure | Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. | Drilling was designed based on known geological models, underground mapping, verified historical data, cross-sectional and 3D interpretation. Drillholes oriented at right angles to strike of deposit, with dip optimised for drill capabilities and the dip of the orebody. |

If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. | This is not considered to be a material factor because of the style of mineralisation and the use of underground drill fans to intersect the mineralisation at various angles. | |

Sample Security | The measures taken to ensure sample security. | All samples were reconciled against the sample submission with any omissions or variations reported to back to the logging geologists. All samples were bagged in a tied numbered calico bag, grouped into green plastic bags. The bags were placed into cages with a sample submission sheet and delivered directly from site to the SGS and Intertek laboratories in Beijing and Tianjin by HHA personnel. |

Audits or reviews | The results of any audits or reviews of sampling techniques and data. | An audit of the underground mining geology systems, including sampling, was carried out in 2018 by Aaron Meakin of CSA Global. This included work on ideal sample spacing. In general, this audit supported current practice. |

Section 2: Reporting of Exploration Results

Criteria | JORC Code explanation | Commentary |

Mineral tenement and land tenure status | Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. | All exploration was conducted on tenements 100% owned by Hebei Hua Ao or its related companies. The leases are the Hua Ao Mining Licence (Zone II and III) and the Hua Ao Retention Licence (Zone V and VIII). The Zone II and III Mining Licence has been granted with a term through to 28th August 2054. See Company Announcement "Renewal of Caijiaying Mining Licence to 2054" dated 19th January 2026.

|

The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. | All tenements are in good standing. The Zone III mining licence extends down to 1000 mRL. There are processes in place in Chinese mining law to allow this to be extended deeper. | |

Exploration done by other parties | Acknowledgment and appraisal of exploration by other parties. | All exploration has been undertaken by Hua Ao or the Third Geological Brigade of Hebei who now form part of the Hua Ao Joint Venture. |

Geology | Deposit type, geological setting and style of mineralisation. | Distal magmatic hydrothermal skarn-style mineralisation at Caijiaying is believed to be related to a Jurassic igneous event that affected the 2.3 billion-year-old metamorphic basement rocks. Base metal and gold mineralisation associated with Jurassic intrusives have replaced favourable horizons in the metamorphic rocks, most notably calcsilicates and marble. Porphyry sills and dykes intruding along faults have then cut across the sequence. |

Drillhole information | A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drillholes: · easting and northing of the drillhole collar · elevation or RL (Reduced Level - elevation above sea level in metres) of the drillhole collar · dip and azimuth of the hole · downhole length and interception depth · hole length. | Greenfield exploration results are not being reported. All drilling related to this announcement has been completed from underground using drill cuddies on varying mine levels, with hole fans drilled up and down dip as well as fanning laterally. The significant intercepts table contains 3D collar co-ordinates, drill hole azimuth and dip for 2025-26 drilling reported here for the Yuan/Fu-Long high-grade gold domain. |

If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case. | NOTE: This announcement relates to 2025-2026 drilling results into a single high-grade gold domain (Yuan Long and Fu Long Lode) within the Caijiaying Zn-Pb-Ag-Au mine. Yuan Long and Fu Long are two of at least five interpreted high grade gold domains at Caijiaying and are the only gold zones that currently has significant new drilling beneath the existing Mineral Resource. Following the recent dramatic increase in gold price and thus the potential in-ground value of high-grade gold domains at Caijiaying, additional resource extension drilling has been designed to better define these structurally controlled gold-rich shoots with the aim to increase gold-rich mining inventory. This announcement aims to demonstrate the nature and continuity of one of the high-grade gold domains at Caijiaying for which there is material new drilling data. Caijiaying is an operating Zn-Pb-Ag-Au mine Exploration results are not routinely reported by the Company unless they reflect a potentially materially different mineralisation style or grade profile. It is not possible to present all historic exploration and resource extension drilling data here. Please refer to the December 2024 MRe for more detailed consolidated information on Mineral Resources and geological context. | |

Data aggregation methods | In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (e.g. cutting of high grades) and cut-off grades are usually Material and should be stated. | Significant intercepts reported here are calculated using a 0.2 g/t Au lower cutoff and a maximum 3m consecutive internal waste. No upper cutoff grade has been applied.

|

Where aggregate intercepts incorporate short lengths of high-grade results and longer lengths of low-grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. | Shorter high-grade intervals within significant intercepts are reported as "incl." Au values and intervals in the significant intercept table. Significant intercepts are presented as (length) weighted average grades and as grams * metres values for the intercept. (for example a 2 metre significant intercept containing 1m @ 10 g/t Au and 1m @ 20 g/t Au would be reported as a 30g*m Au intercept comprising 2m @ 15 g/t Au, incl. 1m @ 20 g/t Au) | |

The assumptions used for any reporting of metal equivalent values should be clearly stated. | Metal equivalent values are not reported here. | |

Relationship between mineralisation widths and intercept lengths | These relationships are particularly important in the reporting of Exploration Results. | |

If the geometry of the mineralisation with respect to the drillhole angle is known, its nature should be reported. | Most holes were drilled approximately orthogonal to mineralisation (+/- 10 degrees); where reported drill holes are not approximately orthogonal to mineralisation an estimated true width is provided based on 3D interpretation of the drill intercept. | |

If it is not known and only the downhole lengths are reported, there should be a clear statement to this effect (e.g. 'downhole length, true width not known'). | ||

Diagrams | Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drillhole collar locations and appropriate sectional views. | All drilling reported here has been completed from underground drill cuddy locations with drill holes fanning up and down as well as laterally. As such, it is difficult to provide serial cross sections, drill hole collar plans etc. 3D long sections and selected horizontal level plan slice views are provided (to the extent possible given the geometry and density of the drilling) in Appendix 2 to demonstrate the mineralisation trends and continuity.

|

Balanced reporting | Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. | Significant intercepts have been reported for all 2025-26 drill holes into the Yuan Long and Fu Long gold domains below the limit of underground development and mining in this zone. No results have been reported outside this domain, and any 2025 drilling into the upper part of Yuan Long (above the 1320m RL) that has since been mined has been excluded. |

Other substantive exploration data | Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. | This data has been covered in detail in the Dec 2024 Mineral Resource estimation report. Refer to Company Announcement "Exceptional Gold Mineralisation At The Caijiaying Mine" dated 15th April 2025. |

Further work | The nature and scale of planned further work (e.g. tests for lateral extensions or depth extensions or large-scale step-out drilling). | Underground drilling is ongoing across the mine site with eight underground drill rigs delivering a mixture of grade control, resource extension and infill drilling, as well as some deeper and more distal conceptual exploration targeting. |

Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. | Areas interpreted to be prospective for down plunge extensions of the high-grade gold domains are highlighted in figures. Discussion of ongoing routine Zn-Pb-Ag-Au resource extension drilling is beyond the scope of this announcement. |

Related Shares:

Griffin Mining