9th Feb 2026 07:00

9 February 2026

Cloudbreak Discovery Plc

('Cloudbreak', or 'the Company')

CDL Proceeds with acquisition of Paterson Project

Cloudbreak Discovery Plc (LSE: CDL), a London Stock Exchange Main Market listed company, is pleased to announce that it is proceeding with the acquisition of 90% of the Paterson Gold-Copper-Molybdenum Project, that covers 888km2 in the Paterson Province of Western Australia, located only 40km southwest of the Telfer Gold-Copper Mine operated by Greatland Gold Plc (Figure 1).

Highlights:

· The Paterson Project covers 888km2 of granted Exploration tenure, 40km south west of Greatland Gold Plc's (GGP London and ASX) Telfer Gold Copper Mine. Telfer has produced 15Moz of gold and combined with Havieron hosts a total of 10.2Moz Au in resources.

· Drilling last completed in 1987 with multiple significant drilling intercepts including:

o 17m @ 1.6% Cu, 317ppm Mo from 84m (87WDRC2)

▪ Including 9m @ 2.6% Cu, 456ppm Mo

o 9m @ 2.0% Cu, 0.14g/t Au, 272ppm Mo from 84m (87WDRC6)

▪ Including 5m @3.1% Cu, 0.20g/t Au, 430ppm Mo

o 11m @ 1.5% Cu, 0.10g/t Au, 181ppm Mo from 83m (87WDRC8)

▪ Including 7m @ 2.1% Cu, 0.15g/t Au, 250ppm Mo

o 13m @ 1.1% Cu, 0.29g/t Au from 107m (87WDRC14)

▪ Including 6m @ 2.0% Cu, 0.27g/t Au

o 8m @ 0.7% Cu, 310ppm Mo from 98m (87WDRC7)

▪ Including 1m @ 3.3% Cu, 0.22g/t Au, 560ppm Mo

· Historic exploration looking for copper not gold

· Significant drilling intercepts are shallow and can be targeted using reverse circulation ("RC") drilling

· Multiple geophysical targets identified which are yet to be drill tested

· Targets associated with magnetic lows and gravity highs

· Mobile MT, a technique utilised by Wishbone Gold Plc and the Telfer Mine in the Paterson Province, to be used over the Paterson Project area

· Paterson Project also surrounds the Kintyre Uranium Project owned by global major Cameco Corp. Kintyre hosts a total indicated resource of 53.5Mlb U3O8

Tom Evans, Cloudbreak's MD, commented; "I am excited and delighted we have been able to proceed with this fantastic opportunity to acquire this asset, in a jurisdiction with significant activity and recent proven success by Wishbone Gold Plc. Located only 40km southwest of the Telfer Gold-Copper Mine operated by Greatland Gold Plc.

Technological advances in geophysics since the 80's have improved greatly with the success of Mobile MT in the Paterson Province, we intend to start off with this geophysical survey, to use as another vector and data layer to refine and rank drill targets not only for copper but for gold as well.

I am excited, for the company and its shareholders, as we progress this great opportunity and I look forward to updating the market as our exploration programs progress."

Location

The Paterson Project (Figure 1) directly surrounds the Kintyre Uranium Deposit and is located 40km south-south-west of Greatland Gold Plc's Telfer Gold-Copper Mine.

Figure 1: Location Plan

Exploration Completed

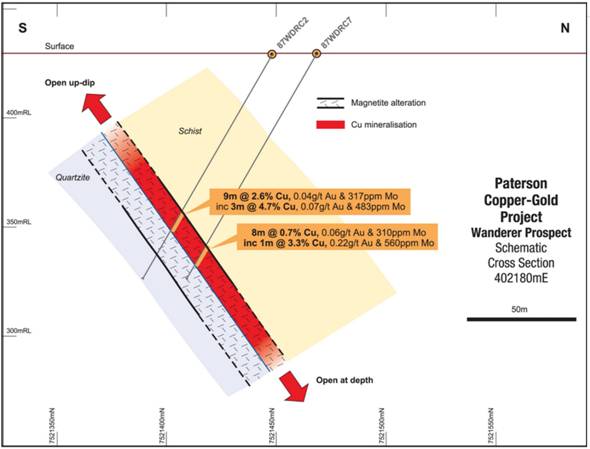

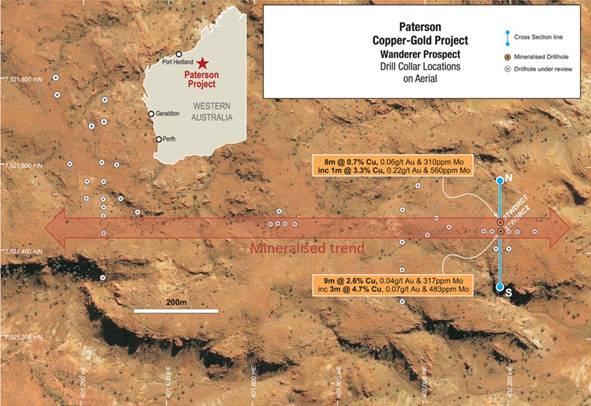

The Wanderer Prospect (Figure 2 and 3) was drilled between 1987 and 1990 by CRA (at significantly lower prevailing copper and gold prices) as part of its uranium exploration expenditure across its nearby Kintyre Project. The majority of drilling was only drilled to 100m from the surface, with multiple holes logged as ending in mineralisation. No follow‐up drilling has occurred in the 35 years since then. Forty-two drill holes were drilled at the Wanderer Prospect on E45/5358 tenement.

Multiple significant drilling intercepts include:

· 17m @ 1.6% Cu, 317ppm Mo from 84m (87WDRC2)

o Including 9m @ 2.6% Cu, 456ppm Mo

· 9m @ 2.0% Cu, 0.14g/t Au, 272ppm Mo from 84m (87WDRC6)

o Including 5m @3.1% Cu, 0.20g/t Au, 430ppm Mo

· 11m @ 1.5% Cu, 0.10g/t Au, 181ppm Mo from 83m (87WDRC8)

o Including 7m @ 2.1% Cu, 0.15g/t Au, 250ppm Mo

· 13m @ 1.1% Cu, 0.29g/t Au from 107m (87WDRC14)

o Including 6m @ 2.0% Cu, 0.27g/t Au

· 8m @ 0.7% Cu, 310ppm Mo from 98m (87WDRC7)

o Including 1m @ 3.3% Cu, 0.22g/t Au, 560ppm Mo

Figure 2: Wanderer Prospect Drill Section

Figure 3: Wanderer Prospect- Drill Collar Plan and Mineralised Trend

Tenure

The Project consists of three granted exploration licences E45/5358, E45/5391 and E45/6244 covering a land area of 888km2.

The ground is contiguous to the west of the Cottesloe base-metal project held by Wishbone Gold Plc.

Regional Geology

The Paterson Orogen is a 2,000km long arcuate belt of folded and metamorphosed sedimentary and igneous rocks that range in age from predominantly Palaeoproterozoic to Neoproterozoic with limited outcrops of Archaean rocks.

The eastern margin of the Paterson Orogen is masked by younger Proterozoic to Phanerozoic sedimentary rocks (Officer and Canning Basins) with sedimentary units of the late Proterozoic Savory Basin on-lapping to the southwest. The main outcropping stratigraphic packages across the bulk of the Paterson Project are the lowermost member of the Mesoproterozoic to Neoproterozoic Yeneena Group, the Coolbro Sandstone, and the Paleoproterozoic Rudall Metamorphic Complex.

Local Geology

The Paleoproterozoic Rudall Metamorphic Complex hosts the Central Tenements surrounding the Kintyre Uranium deposit. At and around Kintyre, the prospective Yandagooge Formation outcrops within the Yandagooge Inlier, consisting of a "basement high" of Rudall Metamorphic Complex surrounded by Neoproterozoic sandstone and Permian glacial tillite. The basement sequence has undergone a minimum of four deformation episodes and is unconformably overlain by Neoproterozoic sandstone and conglomerate deposits of the Yeneena Basin, which have seen at least one major deformation episode.

The dominant host-rock to mineralisation at Kintyre is a garnet-rich, chert-banded, calc-silicate magnetite schistose rock, sandwiched between carbonates and shales of the Yandagooge Formation. These are amphibolite facies metamorphosed rocks, later retrogressively metamorphosed to greenschist facies during or prior to the principal mineralisation phase. Late in syn-D3 or during D4 uranium-bearing, hydrothermal fluids were introduced into the system, depositing pitchblende within northeast dipping dilational zones developed in the S3 cleavage.

In the Kintyre area, the Yandagooge Inlier is surrounded by Coolbro Sandstone, which comprises a thick quartz sandstone sequence with intercalated carbonaceous mudstone and shale interbeds (Jackson & Andrew, 1990). The Coolbro Sandstone, which represents the basal formation of the low-grade metamorphic Neoproterozoic Yeneena Supergroup, exhibits a strong slaty cleavage and has been isoclinally folded and deformed around NW trending axes.

The Central Tenements around the Kintyre deposit are predominantly covered by outcropping northwest-southeast trending, northerly dipping, and folded Coolbro sandstone. Aeolian sand covers areas in the west-central and southeast portions of the tenement. It is believed that these areas are directly underlain by an inlier of the Yandagooge Formation Rudall Metamorphics (Jackson & Andrew, 1990). Rudall Metamorphics outcrop in the west-central area and near the south-eastern corner of the tenement. The north eastern edge of the tenement has outcropping northwest-southeast trending, northerly dipping, and folded Broadhurst Formation.

Exploration Potential and Prospectivity

The Paterson Province hosts several major copper and gold operations, including the Nifty copper mine and the world-class Telfer gold mine. More recently, several new copper-gold discoveries have been made at Winu (Rio Tinto) and Havieron (Greatland Resources PLC�).

Our team reviewed compilation of available geophysical data reprocessed using modern techniques highlights multiple anomalies, including a large "bullseye" magnetic anomaly at Wanderer Prospect within the Central Tenements. The Wanderer Copper-Gold Prospect, first discovered by CRA in 1987, reveals the presence of significant copper, gold and molybdenum values in a wide zone of iron‐oxide alteration extending across more than 1 km of strike. In addition, geochemical assemblage (Cu-Au-Mo) is potentially indicative of a porphyry intrusion as the source of mineralisation. Several other targets with low-magnetics/high gravity signatures have been identified.

At a regional scale, the Paterson Province has potential for large intrusive-related copper and gold targets undercover, requiring geophysical methods, such as Mobile MT by Expert Geophysics Limited, that has been successfully used in the Paterson Province as means of primary target identification.

A review of geophysical and structural data (Figure 4), has identified several compelling exploration opportunities around the existing Wanderer copper-gold project.

Figure 4: RTP Magnetics Left and Gravity Right, illustrating numerous coincident magnetic low and gravity high targets

Deal Terms

Cloudbreak has agreed to acquire a 90% interest in the project via the issue of 330,000,000 shares to Mammoth Minerals Ltd (ASX:M79, "Mammoth").

Under revised terms of the Agreement, Mammoth is to receive:

· 100,000,000 Shares at a deemed issue price of GBP0.0001 per Share at Completion (Completion Consideration Shares);

· 57,500,000 Shares at a deemed issue price of GBP0.0001 per Share if the Tranche 1 Milestone is satisfied on or before 31 December 2029 (Tranche 1 Deferred Consideration Shares);

· 57,500,000 Shares at a deemed issue price of GBP0.0001 per Share if the Tranche 2 Milestone is satisfied on or before 31 December 2029 (Tranche 2 Deferred Consideration Shares);

· 57,500,000 Shares at a deemed issue price of GBP0.0001 per Share if the Tranche 3 Milestone is satisfied on or before 31 December 2029 (Tranche 3 Deferred Consideration Shares); and

· 57,500,000 Shares at a deemed issue price of GBP0.0001 per Share if the Tranche 4 Milestone is satisfied on or before 31 December 2029 (Tranche 4 Deferred Consideration Shares)

Deferred Consideration Shares | Milestone |

Tranche 1 Deferred Consideration Shares | Completion of the following at the Tenements: (a) heritage surveys; (b) assessment of historic tracks; (c) mobile camp setup; (d) renaissance rock chip sampling; and (e) litho-structural mapping, (collectively, Tranche 1 Milestone). |

Tranche 2 Deferred Consideration Shares | Completion of the following at the Tenements: (a) soil sampling; and (b) track construction, (collectively, Tranche 2 Milestone). |

Tranche 3 Deferred Consideration Shares | Completion of ground IP/magnetics of select prospects at the Tenements (Tranche 3 Milestone). |

Tranche 4 Deferred Consideration Shares | Completion of the following at the Tenements: (a) RC drilling of select prospects; and/or (b) diamond drilling of select prospects, With a total of 3000m drilled (collectively, Tranche 4 Milestone). |

Mammoth is to retain a 10% free carried interest in the Project until the completion of a Definitive Feasibility Study with a positive NPV.

This announcement contains information which, prior to its disclosure, was inside information as stipulated under Regulation 11 of the Market Abuse (Amendment) (EU Exit) Regulations 2019/310 (as amended).

For additional information please contact:

Cloudbreak Discovery PLC | Peter Huljich, Chairman Tom Evans, Managing Director | Tel: +44 207 887 6139 Tel: +44 7851 703440 |

AlbR Capital Limited (Financial Adviser) | David Coffman / Dan Harris | Tel: +44 207 469 0930 |

Marex Financial (Broker) | Angelo Sofocleous / Keith Swann / Matt Bailey | Tel: +44 (0) 207 655 6000 Email: [email protected] |

Competent Persons Statement

The Information in this report that relates to exploration results, mineral resources or ore reserves is based on information compiled by Mr Edward Mead, who is a Fellow of the Australasian Institute of Mining and Metallurgy. Mr Mead is a consultant to Cloudbreak Discovery Plc and employed by Doraleda Pty Ltd. Mr Mead has sufficient experience which is relevant to the style of mineralisation and type of deposits under consideration and to the activity that he is undertaking to qualify as a Competent Person as defined in the 2012 edition of the `Australian Code for Reporting Exploration Results, Mineral Resources and Ore Reserves' (the JORC Code). Mr Mead consents to the inclusion of this information in the form and context in which it appears in this report.

Table 1: Significant Assays (>0.3% Cu or 0.3ppm Au)

Hole | From (m) | To (m) | Interval (m) | Cu % | Au | Mo ppm |

87WDRC1 | 25 | 28 | 3 | 0.30% | 0 | 6 |

87WDRC10 | 53 | 54 | 1 | 0.31% | 0.25 | 350 |

87WDRC12 | 111 | 115 | 4 | 0.70% | 0.35 | 18 |

87WDRC13 | 101 | 102 | 1 | 0.34% | 0.07 | 34 |

87WDRC13 | 102 | 103 | 1 | 0.35% | 0.09 | 40 |

87WDRC13 | 105 | 106 | 1 | 1.11% | 0.12 | 18 |

87WDRC13 | 108 | 109 | 1 | 0.45% | 0.04 | 33 |

87WDRC13 | 109 | 110 | 1 | 0.88% | 0.06 | 37 |

87WDRC13 | 110 | 111 | 1 | 0.63% | 0.16 | 43 |

87WDRC13 | 111 | 112 | 1 | 0.83% | 0.09 | 38 |

87WDRC14 | 77 | 78 | 1 | 1.22% | 0.15 | 145 |

87WDRC14 | 107 | 110 | 3 | 0.56% | 0.17 | 74 |

87WDRC14 | 110 | 112 | 2 | 0.25% | 0.65 | 18 |

87WDRC14 | 114 | 115 | 1 | 2.11% | 0.59 | 26 |

87WDRC14 | 115 | 116 | 1 | 1.17% | 0.17 | 29 |

87WDRC14 | 116 | 118 | 2 | 2.68% | 0.28 | 22 |

87WDRC14 | 118 | 120 | 2 | 1.82% | 0.15 | 30 |

87WDRC17 | 0 | 5 | 5 | 0.01% | 0.38 | 21 |

87WDRC2 | 84 | 85 | 1 | 0.53% | 0.02 | 460 |

87WDRC2 | 88 | 89 | 1 | 0.89% | 0.04 | 280 |

87WDRC2 | 89 | 90 | 1 | 1.15% | 0.04 | 1270 |

87WDRC2 | 90 | 91 | 1 | 1.68% | 0.03 | 1000 |

87WDRC2 | 91 | 92 | 1 | 4.00% | 0.09 | 610 |

87WDRC2 | 92 | 93 | 1 | 3.61% | 0.06 | 620 |

87WDRC2 | 93 | 94 | 1 | 6.51% | 0.06 | 220 |

87WDRC2 | 94 | 95 | 1 | 1.20% | 0.01 | 15 |

87WDRC2 | 95 | 97 | 2 | 2.34% | 0.03 | 44 |

87WDRC2 | 97 | 99 | 2 | 0.52% | 0.03 | 40 |

87WDRC2 | 99 | 101 | 2 | 0.32% | 0.01 | 49 |

87WDRC22 | 75 | 80 | 5 | 0.62% | 0.16 | 13 |

87WDRC22 | 80 | 85 | 5 | 0.10% | 0.3 | 9 |

87WDRC24 | 70 | 73 | 3 | 0.33% | 0.04 | 34 |

87WDRC24 | 73 | 77 | 4 | 0.71% | 0.09 | 41 |

87WDRC24 | 77 | 80 | 3 | 0.61% | 0.06 | 30 |

87WDRC26 | 82 | 86 | 4 | 0.68% | 0.09 | 28 |

87WDRC3 | 83 | 84 | 1 | 0.45% | 0.01 | 7 |

87WDRC3 | 85 | 86 | 1 | 0.52% | 0.07 | 140 |

87WDRC3 | 86 | 88 | 2 | 0.42% | 0.03 | 69 |

87WDRC6 | 84 | 85 | 1 | 5.18% | 0.29 | 620 |

87WDRC6 | 85 | 86 | 1 | 2.60% | 0.22 | 720 |

87WDRC6 | 86 | 87 | 1 | 2.56% | 0.21 | 350 |

87WDRC6 | 87 | 88 | 1 | 2.31% | 0.18 | 290 |

87WDRC6 | 88 | 89 | 1 | 3.05% | 0.11 | 169 |

87WDRC6 | 89 | 90 | 1 | 1.01% | 0.1 | 81 |

87WDRC6 | 90 | 91 | 1 | 0.57% | 0.04 | 59 |

87WDRC6 | 91 | 92 | 1 | 0.42% | 0.03 | 42 |

87WDRC6 | 92 | 93 | 1 | 0.72% | 0.04 | 121 |

87WDRC7 | 98 | 103 | 5 | 0.31% | 0.01 | 46 |

87WDRC7 | 103 | 104 | 1 | 3.27% | 0.22 | 560 |

87WDRC7 | 104 | 105 | 1 | 0.71% | 0.08 | 360 |

87WDRC7 | 105 | 106 | 1 | 0.34% | 0.09 | 1330 |

87WDRC8 | 83 | 84 | 1 | 0.88% | 0.11 | 200 |

87WDRC8 | 84 | 85 | 1 | 2.01% | 0.26 | 280 |

87WDRC8 | 85 | 86 | 1 | 2.18% | 0.14 | 178 |

87WDRC8 | 86 | 87 | 1 | 2.02% | 0.15 | 260 |

87WDRC8 | 87 | 88 | 1 | 3.23% | 0.18 | 420 |

87WDRC8 | 88 | 89 | 1 | 2.59% | 0.11 | 210 |

87WDRC8 | 89 | 90 | 1 | 1.81% | 0.08 | 200 |

87WDRC8 | 90 | 92 | 2 | 0.39% | 0.01 | 43 |

87WDRC8 | 92 | 94 | 2 | 0.70% | 0.03 | 77 |

88WDD03 | 89 | 90 | 1 | 0.67% | 0.04 | 53 |

88WDD03 | 90 | 91 | 1 | 0.36% | 0.03 | 40 |

88WDD03 | 190 | 191 | 1 | 0.61% | 0.08 | 78 |

88WDD03 | 191 | 192 | 1 | 0.43% | 0.06 | 87 |

88WDRC27 | 43 | 44 | 1 | 0.19% | 0.99 | 24 |

88WDRC28 | 58 | 62 | 4 | 0.48% | 0 | 11 |

88WDRC36 | 90 | 95 | 5 | 0.32% | 0.02 | 9 |

88WDRC36 | 95 | 100 | 5 | 0.46% | 0.1 | 20 |

Table 2: Collar location and Hole Type

Hole ID | Easting | Northing | RL (m) | Total Depth (m) | Dip | Azimuth | Hole Type |

87WDRC1 | 402140 | 7521450 | 430 | 104 | -60 | 180 | RC |

87WDRC2 | 402180 | 7521450 | 430 | 120 | -60 | 180 | RC |

87WDRC3 | 402220 | 7521450 | 430 | 120 | -60 | 180 | RC |

87WDRC4 | 402200 | 7521410 | 430 | 120 | -60 | 180 | RC |

87WDRC5 | 402170 | 7521410 | 430 | 120 | -60 | 180 | RC |

87WDRC6 | 402160 | 7521450 | 430 | 116 | -60 | 180 | RC |

87WDRC7 | 402180 | 7521470 | 430 | 120 | -60 | 180 | RC |

87WDRC8 | 402200 | 7521450 | 430 | 109 | -60 | 180 | RC |

87WDRC9 | 402260 | 7521450 | 430 | 98 | -60 | 180 | RC |

87WDRC10 | 402060 | 7521460 | 430 | 89 | -60 | 180 | RC |

87WDRC11 | 402030 | 7521480 | 430 | 120 | -60 | 180 | RC |

87WDRC12 | 402010 | 7521440 | 430 | 120 | -60 | 180 | RC |

87WDRC13 | 401250 | 7521520 | 450 | 120 | -90 | 0 | RC |

87WDRC14 | 401250 | 7521480 | 450 | 120 | -90 | 0 | RC |

87WDRC15 | 401210 | 7521520 | 450 | 114 | -90 | 0 | RC |

87WDRC16 | 401250 | 7521560 | 450 | 109 | -90 | 0 | RC |

87WDRC17 | 401290 | 7521520 | 450 | 115 | -90 | 0 | RC |

87WDRC18 | 401330 | 7521490 | 450 | 119 | -90 | 0 | RC |

87WDRC19 | 401170 | 7521600 | 450 | 120 | -90 | 0 | RC |

87WDRC20 | 401210 | 7521560 | 450 | 120 | -90 | 0 | RC |

87WDRC21 | 401250 | 7521440 | 450 | 120 | -90 | 0 | RC |

87WDRC22 | 401642 | 7521465 | 450 | 98 | -60 | 180 | RC |

87WDRC23 | 401658 | 7521465 | 450 | 100 | -60 | 180 | RC |

87WDRC24 | 401675 | 7521465 | 450 | 100 | -60 | 180 | RC |

87WDRC25 | 401700 | 7521465 | 450 | 96 | -60 | 180 | RC |

87WDRC26 | 401662 | 7521493 | 450 | 100 | -60 | 180 | RC |

88WDRC27 | 401245 | 7521605 | 450 | 80 | -60 | 240 | RC |

88WDRC28 | 401280 | 7521600 | 450 | 81 | -60 | 240 | RC |

88WDRC29 | 401220 | 7521690 | 450 | 69 | -60 | 250 | RC |

88WDRC30 | 401140 | 7521760 | 451 | 54 | -60 | 250 | RC |

88WDRC31 | 401135 | 7521800 | 448 | 69 | -60 | 240 | RC |

88WDRC32 | 401250 | 7521750 | 450 | 106 | -90 | 0 | RC |

88WDRC33 | 401250 | 7521700 | 440 | 87 | -60 | 200 | RC |

88WDRC34 | 401250 | 7521335 | 450 | 105 | -90 | 0 | RC |

88WDRC35 | 401950 | 7521360 | 430 | 106 | -90 | 0 | RC |

88WDRC36 | 401950 | 7521285 | 450 | 106 | -90 | 0 | RC |

88WDRC37 | 401950 | 7521425 | 440 | 106 | -90 | 0 | RC |

87WDD01 | 401950 | 7521500 | 415 | 287.7 | -61 | 181 | DD |

87WDD02 | 401985 | 7521555 | 440 | 117 | -70 | 180 | DD |

88WDD03 | 401250 | 7521500 | 420 | 212.7 | -90 | 0 | DD |

88WDD04 | 402180 | 7521480 | 434 | 200.8 | -90 | 0 | DD |

90WDD05 | 401950 | 7521425 | 440 | 409.9 | -90 | 0 | DD |

APPENDIX 1: JORC INFORMATION

The following Tables are provided to ensure compliance with the JORC Code (2012 Edition) requirements for the reporting of Exploration Results at Firetail Project, Patersons. Western Australia

Section 1: Sampling Techniques and Data

(Criteria in this section applies to all succeeding sections)

Criteria | JORC Code explanation | Commentary |

Sampling techniques | Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. Aspects of the determination of mineralisation that are Material to the Public Report. In cases where 'industry standard' work has been done this would be relatively simple (eg 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases, more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information. | The historic drilling was completed between 1987 to 1990 by CRA exploration. The assay results have been digitised from the final report A47265. No description of sampling techniques were described in the report. It is assumed the sampling was completed to industry standards at that time. RC drill holes have been sampled with 2-10m composites and areas where mineralisation was visually confirmed sampling was reduced to 1m intervals. The most common composite width in unmineralized areas is 5m. The size of the diamond drill core was not described in the report. Sample widths in drill holes 87WDD01-02 and 88WDD03-04 ranged from 0.5m to 7m. In unmineralized lithologies samples are typically 2m-5m and in mineralised areas samples mostly 1m. In drill hole 90WDD05 samples were over large widths ranging from 6.9m to 13.1m with an average sample width of 9.8m. Due to the large intervals it is assumed that a quarter core or similar (<25%) of the core was assayed in this hole. |

Drilling techniques | Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). | RC and diamond drilling techniques were used. Drilling specifics were not described in the historic report (A47265). No surveys were tabulated in the report. |

Drill sample recovery | Method of recording and assessing core and chip sample recoveries and results assessed. Measures taken to maximise sample recovery and ensure representative nature of the samples. Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. | Drilling specifics were not described in the report. |

Logging | Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. The total length and percentage of the relevant intersections logged. | Drill holes were all logged to an appropriate standard. Logging details include, lithologies, texture, minerals, colour and magnetic susceptibility. |

Sub-sampling techniques and sample preparation | If core, whether cut or sawn and whether quarter, half or all core taken. If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. For all sample types, the nature, quality and appropriateness of the sample preparation technique. Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. Measures taken to ensure that the sampling is representative of the in-situ material collected, including for instance results for field duplicate/second-half sampling. Whether sample sizes are appropriate to the grain size of the material being sampled. | It is assumed CRA utilised industry standards sampling procedures. Sampling techniques were not described in the historic report. Some of the sample intervals are not appropriate for base metal and gold mineralisation due to the large sample widths. The sample widths and also standard hole depths reflect the target horizon as basement and the likely target commodity as uranium. Any sub-sampling was purely "out of interest" at the time. Large sampling intervals in this style of mineralisation has likely diluted the grade of the base metals and precious metals. |

Quality of assay data and laboratory tests | The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established. | The analytical methods and laboratory were not described in the historic report (A47265). It is assumed CRA use a reputable laboratory. The Au assays were presented as ppm. Drill holes 87WDRC1-26 had a lower detection limit of 0.003ppm and drill holes 88WDRC27-37 had a lower detection limit of 0.005ppm. 28 other elements were assayed using an unknown technique. The lower detection limit for Cu is unknown, but the lowest value is 3ppm. The lower detection limit for Mo is 3ppm. |

Verification of sampling and assaying | The verification of significant intersections by either independent or alternative company personnel. The use of twinned holes. Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. Discuss any adjustment to assay data. | No verification has been completed on the significant intersections. •CRA was a well-known exploration company in Western Australia and found and drilled many prospects. The exploration completed on the Wanderer Prospect was conducted over 3 field seasons and multiple drill holes have been drilled through the mineralised system confirming the grade and widths. |

Location of data points | Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. Specification of the grid system used. Quality and adequacy of topographic control. | No description of how the drill holes were surveyed is in the historic report (A47265). The drill holes were most likely surveyed by a professional surveyor. Grid system is AMG84 Zone 51. Quality and adequacy of topographic control was not described in the historic report. |

Data spacing and distribution | Data spacing for reporting of Exploration Results. Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. Whether sample compositing has been applied. | Data spacing and distribution is sufficient for an exploration project. Further drilling is required to understand the geology and mineralisation potential. Sample compositing has been applied to all drill holes and is described in detail in the Sampling Techniques section of this Table 1. Data not designed for, and is not suitable for an MRE. |

Orientation of data in relation to geological structure | Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. | Drilling appears to be intersecting the mineralised horizon at a roughly perpendicular angle. Further drilling is needed to fully understand the geometry of the mineralisation. There appears to be no apparent sample bias. |

Sample security | The measures taken to ensure sample security. | Sample security not known. |

Audits or reviews | The results of any audits or reviews of sampling techniques and data. | Results have been added to a database and reviewed. |

Section 2: Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section)

Criteria | JORC Code explanation | Commentary |

Mineral tenement and land tenure status | Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. | The prospect is located on granted Exploration licenses, E45/5358, E45/5391 and E45/6244 that cover 888km2. A Heritage Agreement has been signed with the Martu people, as the Traditional Owners on which the Wanderer Prospect sits. |

Exploration done by other parties | Acknowledgment and appraisal of exploration by other parties. | Wanderer was first recognised by CRA as a high priority radiometric anomaly in 1986 and was confirm with anomalous base metals and Au rock chips that year. Over the next 4 years to 1990 CRA completed partial soils over the prospect, rock chipping, ground magnetics, IP, and drilling. No further base metals or gold exploration has been completed over the area since 1990. Uranium exploration has been active over the project area and Cameco has completing most of the work which includes ground gravity and ground radiometrics over the Wanderer prospect. |

Geology | Deposit type, geological setting and style of mineralisation. | The Paterson Copper-Gold Project lies within the Paterson Province of Western Australia and comprises two lithological packages; the Rudall Metamorphic Complex ('RMC') and the Yeneena Group. The RMC contains orthogneiss and metasediments overlying an Archaean or younger Proterozoic basement. A large fault passes through the project separating the RMC in the South West from the younger Yeneena Group in the North East. The Yeneena Group comprises a basal Coolbro Sandstone +/- shale and carbonaceous mudstone. Overlying this is the Broadhurst Formation which contains carbonaceous shale, sandstone, dolomite and limestone. Late tertiary and quaternary regolith sequences comprising colluvium, alluvium, calcrete and aeolian sands overlie these bedrock packages in areas where significant erosion and weathering of the underlying bedrock has taken place. |

Drill hole Information | A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes: easting and northing of the drill hole collar elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar dip and azimuth of the hole down hole length and interception depth hole length. If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case. | Significant drill results and all collar locations included within the release. |

Data aggregation methods | In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated. Where aggregate intercepts incorporate short lengths of high-grade results and longer lengths of low-grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. The assumptions used for any reporting of metal equivalent values should be clearly stated. | Significant intersections (>0.3% Cu or 0.3ppm Au) have been calculated with a minimum of 1m downhole length. No metal equivalent values are reported |

Relationship between mineralisation widths and intercept lengths | These relationships are particularly important in the reporting of Exploration Results. If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg 'down hole length, true width not known'). | Drilling appears to be intersecting the mineralised horizon at a roughly orthogonal angle |

Diagrams | Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views. | Appropriate Diagrams included in this release |

Balanced reporting | Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. | Significant exploration drill results are included in this Report. |

Other substantive exploration data | Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. | To date, only exploration drilling and geophysical and geochemical surveys (and associated activities) have been undertaken on the project. No other modifying factors have been investigated at this stage |

Further work | The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling). Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. | Further work to include Mobile Mt and will include further systematic exploration drilling. |

Related Shares:

Cloudbreak